Flexible substrate package-based shielding structure and manufacturing process thereof

A flexible substrate and shielding structure technology, applied in the fields of magnetic field/electric field shielding, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc. Conducive to miniaturization, easy heat dissipation, good reliability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

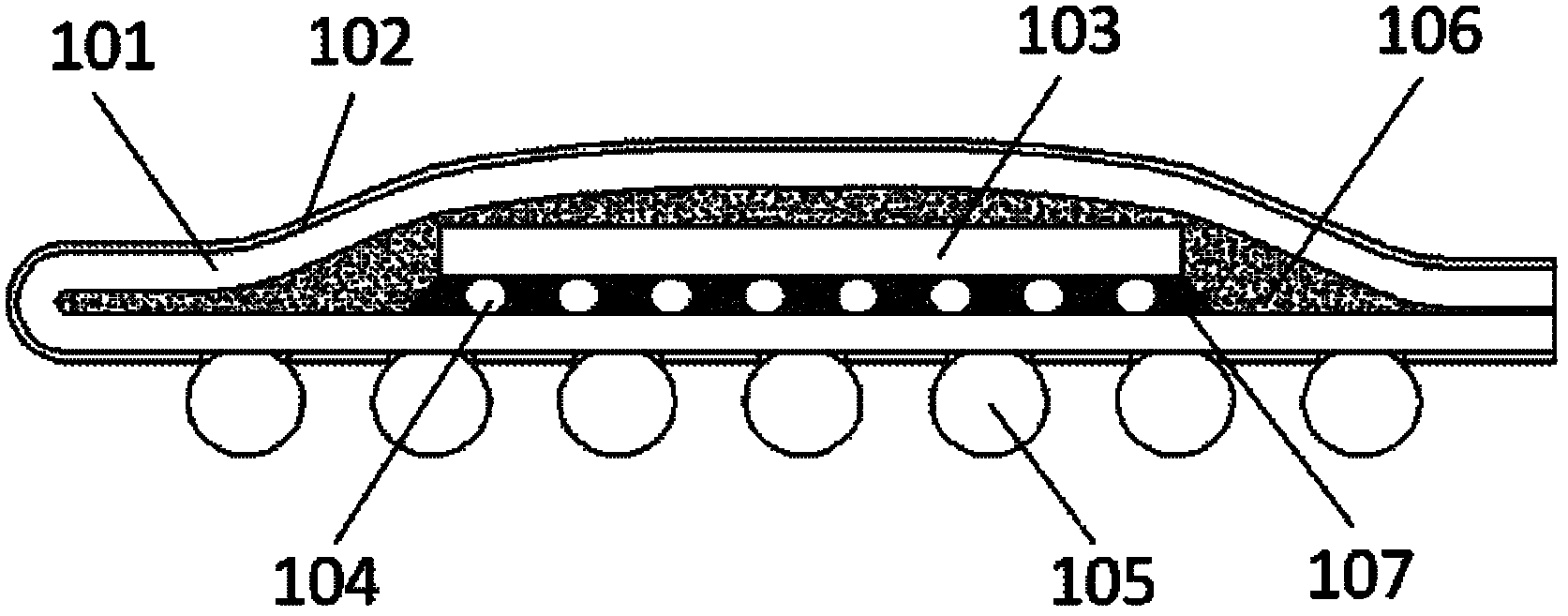

[0043] figure 1 is a cross-sectional view of a single-layer shielding structure based on a flexible substrate package according to the first embodiment of the present invention. Such as figure 1 As shown, the bare chip 103 is bonded on the flexible substrate 101 in a Flip-chip manner, and the underfill glue 107 is used to protect the Flip-Chip bumps 104 . The shielding layer 102 is located on the flexible substrate 101 and is connected to the substrate ground / power circuit or directly connected to the ground / power BGA solder ball 105 through conductive vias. The material of the shielding layer is a metal film such as copper or coated with shielding glue. The shielding glue includes common shielding glue and new colloids containing high magnetic permeability and high conductivity micro-particles such as iron, cobalt, nickel or corresponding alloys. A potting compound 106 such as plastic compound is filled between the folded flexible substrate 101 and the bare chip 103 to fix th...

no. 2 example

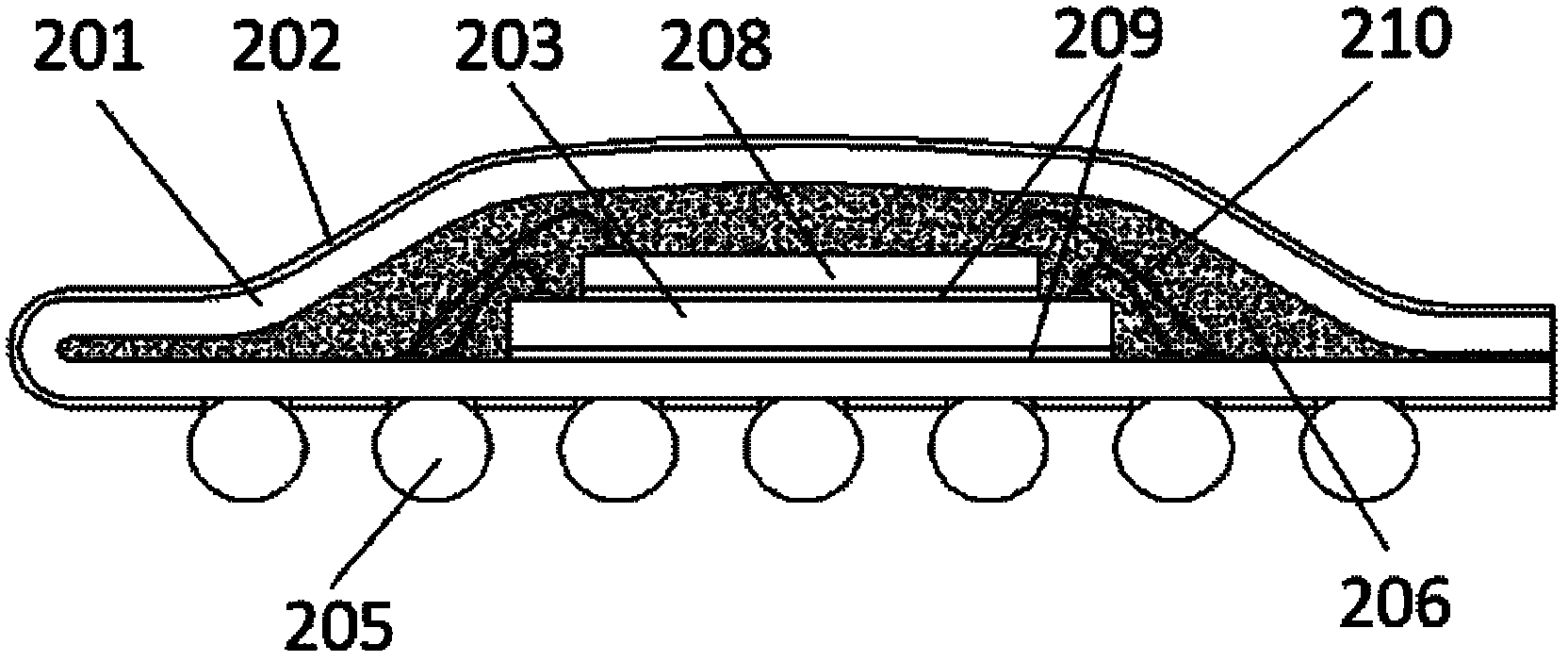

[0045] figure 2 is a cross-sectional view of a single-layer shielding structure based on flexible substrate packaging according to the second embodiment of the present invention. Such as figure 2 As shown, the bare chip 203 is fixed on the chip 208 through the adhesive 209, the bare chip 208 is fixed on the flexible substrate 201 through the adhesive, the shielding layer 202 is located on the flexible substrate 201, and is grounded / connected to the substrate through the conductive via hole The power circuit is connected or directly connected to the ground / power BGA ball 205 . The material of the shielding layer is a metal film such as copper or coated with shielding glue. The shielding glue includes common shielding glue and new colloids containing high magnetic permeability and high conductivity micro-particles such as iron, cobalt, nickel or corresponding alloys. A potting compound 206 such as plastic compound is filled between the folded flexible substrate 201 and the b...

no. 3 example

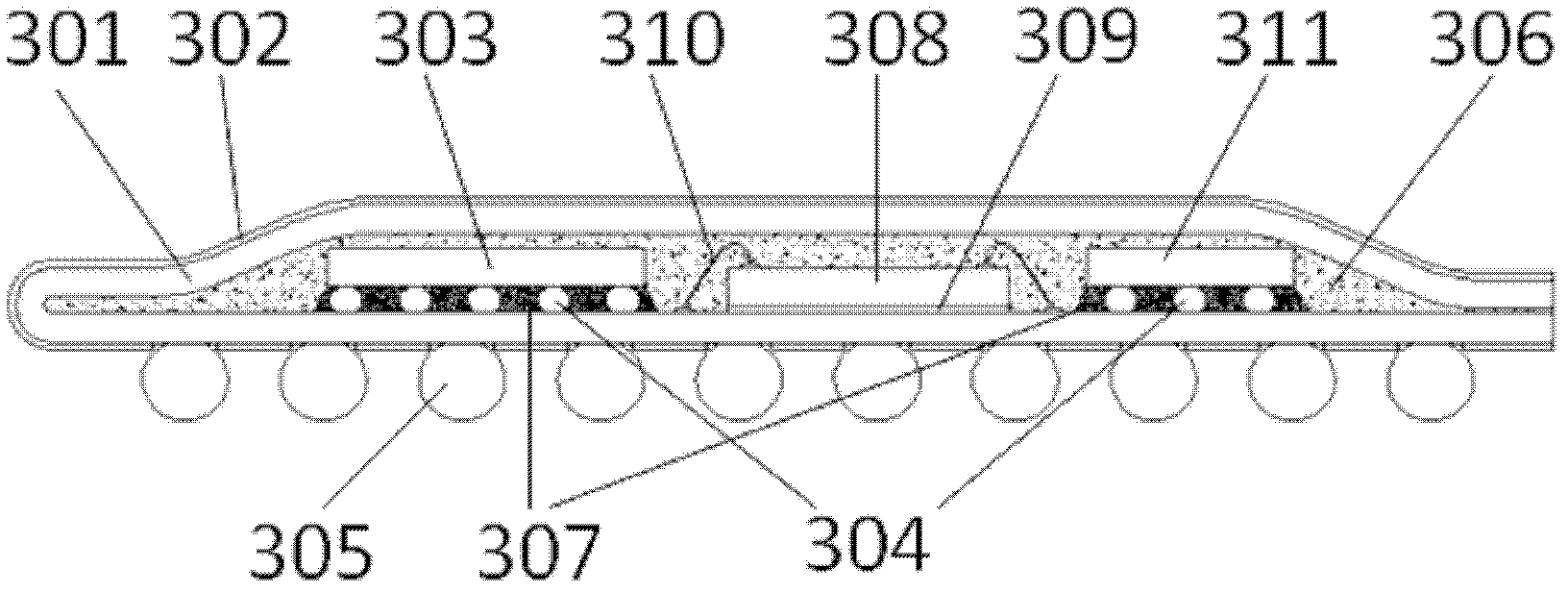

[0047] image 3 is a cross-sectional view of a single-layer shielding structure based on flexible substrate packaging according to the third embodiment of the present invention. Such as image 3 As shown, the bare chips 301 and 311 are bonded on the flexible substrate 301 in a Flip-chip manner, the underfill glue 307 is used to protect the Flip-Chip bumps 304, and the bare chip 308 is fixed on the flexible substrate 301 by an adhesive 309. The shielding layer 302 is located on the flexible substrate 301 and connected to the substrate ground / power circuit or directly connected to the ground / power BGA solder ball 305 through conductive vias. The material of the shielding layer is a metal film such as copper or coated with shielding glue. The shielding glue includes common shielding glue and new colloids containing high magnetic permeability and high conductivity micro-particles such as iron, cobalt, nickel or corresponding alloys. A potting compound 306 such as plastic compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com