Aqueous lithium (sodium) ion battery mixed negative material

A technology for ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of small theoretical capacity of lithium titanium phosphate, serious hydrogen evolution problem, low specific energy, etc., and achieve low production cost, high safety, Effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

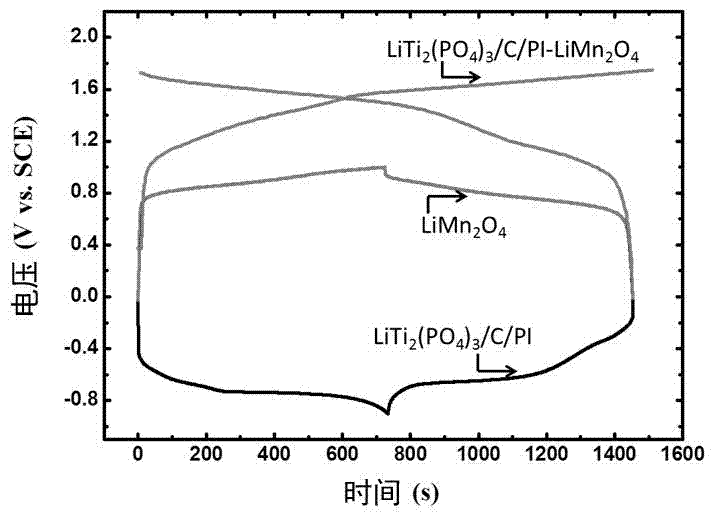

Embodiment 1

[0016] The mixed anode material uses 1, 4, 5, 8 naphthalene tetracarboxylic dianhydride as the substrate and polyimide (PI) polymerized with ethylenediamine, carbon-coated LiTi 2 (PO 4 ) 3 , acetylene black (conductive material), the mixed mass ratio of the three is LiTi 2 (PO 4 ) 3 : PI: acetylene black = 60:30:10, the mixing method is grinding mixing. After the mixing is completed, add a binder with a mass ratio of 5% of the total mass to mix the slurry, then evenly coat it on the stainless steel mesh current collector, and press it into an electrode after drying. The positive electrode material adopts spinel type LiMn for commercial lithium-ion batteries 2 O 4 . The composition of the positive electrode is based on LiMn 2 O 4 : carbon black: binder = 85:5:10 weight ratio mixed slurry, evenly coated on the stainless steel mesh current collector, dried and pressed into electrodes. In this embodiment, the actual capacity of the positive electrode material is 100 mAh / ...

Embodiment 2

[0018] The mixed anode material uses 1, 4, 5, 8 naphthalene tetracarboxylic dianhydride as the substrate and polyimide (PI) polymerized with ethylenediamine, carbon-coated LiTi 2 (PO 4 ) 3 , acetylene black (conductive material), the mixed mass ratio of the three is LiTi 2 (PO 4 ) 3 : PI: acetylene black = 50:30:20, the mixing method is grinding mixing. After the mixing is completed, add a binder with a mass ratio of 5% of the total mass to mix the slurry, then evenly coat it on the stainless steel mesh current collector, and press it into an electrode after drying. The positive electrode material adopts spinel type LiMn for commercial lithium-ion batteries 2 O 4 . The composition of the positive electrode is based on LiMn 2 O 4: carbon black: binder = 85:5:10 weight ratio mixed slurry, evenly coated on the stainless steel mesh current collector, dried and pressed into electrodes. In this embodiment, the actual capacity of the positive electrode material is 100 mAh / g...

Embodiment 3

[0020] The mixed anode material uses 1, 4, 5, 8 naphthalene tetracarboxylic dianhydride as the substrate and polyimide (PI) polymerized with ethylenediamine, carbon-coated LiTi 2 (PO 4 ) 3 , acetylene black (conductive material), the mixed mass ratio of the three is LiTi 2 (PO 4 ) 3 : PI: acetylene black = 30:50:20, the mixing method is grinding mixing. After the mixing is completed, add a binder with a mass ratio of 5% of the total mass to mix the slurry, then evenly coat it on the stainless steel mesh current collector, and press it into an electrode after drying. The positive electrode material adopts spinel type LiMn for commercial lithium-ion batteries 2 O 4 . The composition of the positive electrode is based on LiMn 2 O 4 : carbon black: binder = 85:5:10 weight ratio mixed slurry, evenly coated on the stainless steel mesh current collector, dried and pressed into electrodes. In this embodiment, the actual capacity of the positive electrode material is 100 mAh / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com