Preparation method of polymer nanofiber membrane containing perfluorinated sulfonic acid

A nanofiber membrane, perfluorosulfonic acid technology, applied in the direction of conjugated synthetic polymer rayon, synthetic polymer rayon chemical post-treatment, fiber treatment, etc., can solve the problem of reducing the weight ratio activity of perfluorosulfonic acid, Can not be effectively used, not easy to stretch and other problems, to achieve the effect of controllable macro size, low equipment cost, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of perfluorosulfonic acid / polyacrylonitrile nanofiber membrane

[0047] 1) Prepare polymer solution

[0048] Weigh 2.5g of polyacrylonitrile (PAN) and dissolve it in 14.0g of N,N-dimethylacetamide (DMAc), add 2.5g of perfluorosulfonic acid (PFSA), and magnetically stir in a water bath at 60°C until uniform to obtain an organic solution ;

[0049] 2) Preparation of organic-inorganic suspension

[0050] Add 1.0 g of calcium carbonate (CaCO 3 ) nanoparticles, ultrasonic treatment for 2 hours and magnetic stirring at room temperature for 12 hours to obtain a uniform organic-inorganic suspension;

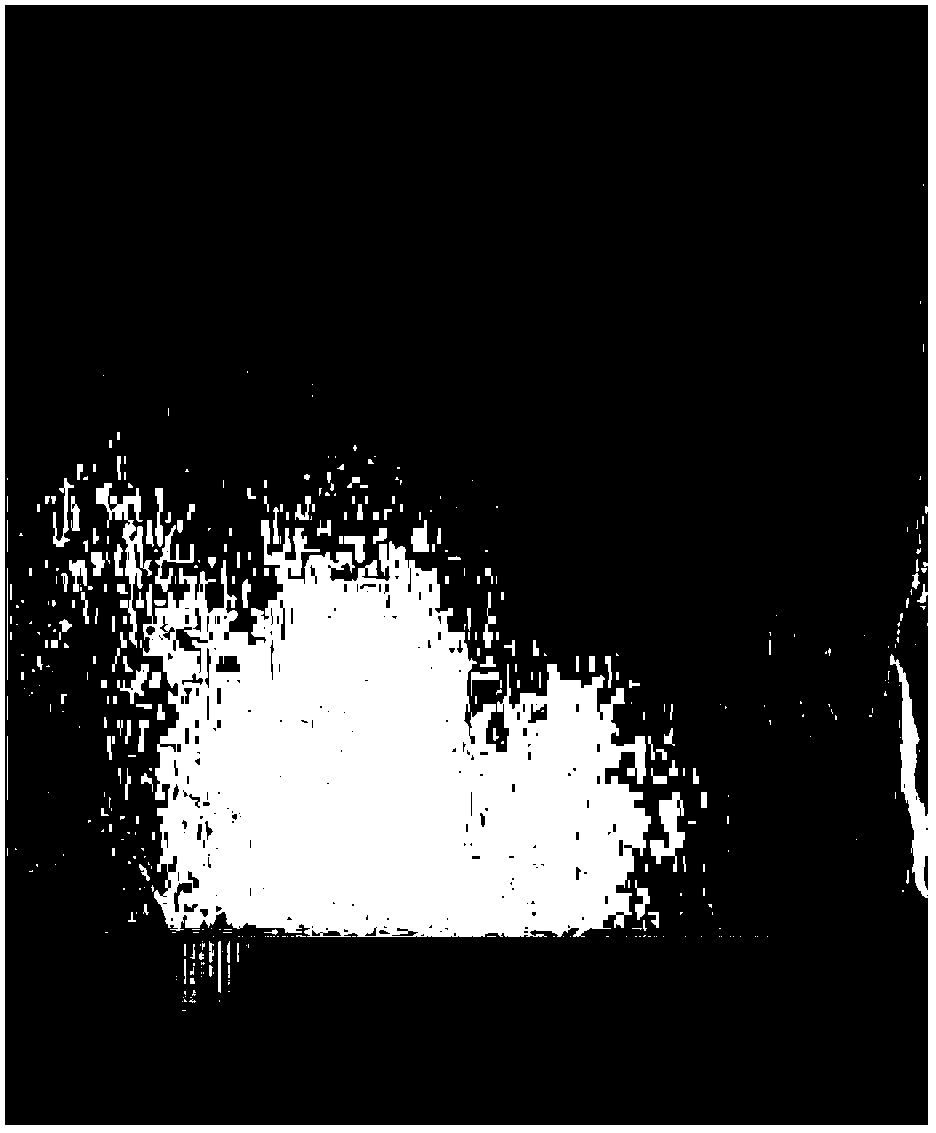

[0051] 3) Preparation of nanofibrous membranes containing inorganic particles

[0052] The above-mentioned organic-inorganic suspension was left to defoam for 12 hours, and then transferred to an electrospinning device for spinning. The conditions were: power supply voltage 15kV, feed rate 0.5ml / h, adjust receiver and spinneret (inner diameter 0.4mm) The distance be...

Embodiment 2

[0057] Preparation of perfluorosulfonic acid / polyvinyl alcohol nanofiber membrane

[0058] 1) Prepare polymer solution

[0059] Weigh 2.0g of methanol, 4.0g of n-propanol, 14.0g of deionized water, stir at room temperature to form a uniform mixed solvent; take 1.2g of polyvinyl alcohol (PVA: 1799) and 3.0g of perfluorosulfonic acid (PFSA), heat at 95°C Dissolve, magnetically stir until uniform, and obtain an organic solution;

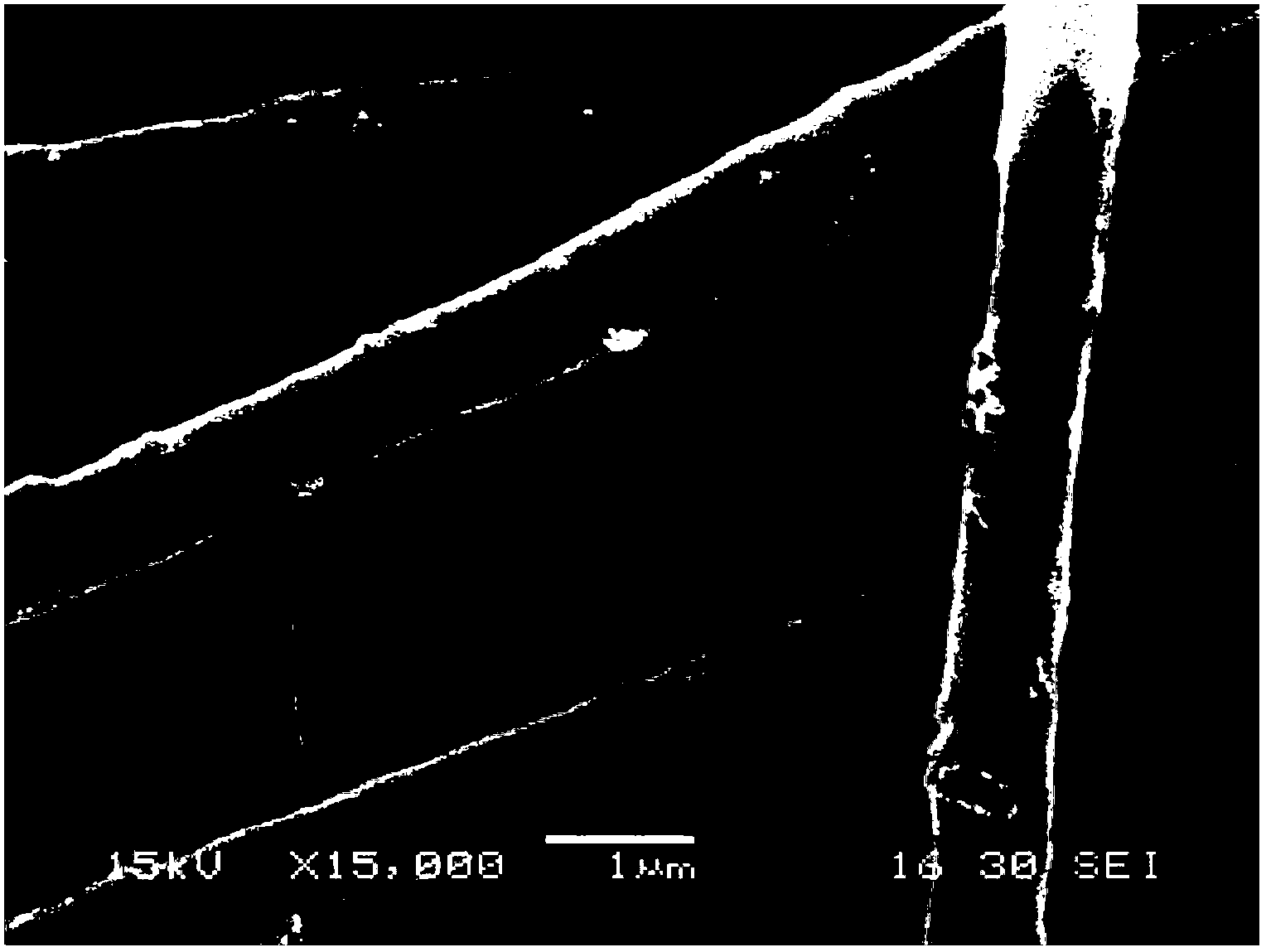

[0060] 2) Preparation of nanofibrous membrane

[0061] The above solution is cooled to room temperature, left standing for defoaming for 24h, and transferred to an electrospinning device for spinning, the conditions are: power supply voltage 18kV, feed rate 0.3ml / h, adjust receiver and spinneret (inner diameter 0.4mm) The distance between them is 10cm, and the perfluorosulfonic acid / polyvinyl alcohol nanofibrous membrane ( figure 2 );

[0062] The obtained nanofibrous membrane has a thickness of about 50 μm and a specific surface area of 32 m 2 ...

Embodiment 3

[0064] Preparation of perfluorosulfonic acid / polyethersulfone nanofiber membrane

[0065] 1) Prepare polymer solution

[0066] Weigh 3.0g of polyethersulfone (PES) and dissolve it in 14.0g of N,N-dimethylacetamide (DMAc), add 1.0g of perfluorosulfonic acid (PFSA), and magnetically stir in a water bath at 60°C until uniform to obtain an organic solution ;

[0067] 2) Prepare an organic solution containing additives

[0068] Under the condition of strong stirring, slowly add 2.0 g of ethanol dropwise to the above organic solution, and after the dropwise addition is completed, keep magnetic stirring at room temperature for 12 hours to obtain a uniform organic solution containing additives;

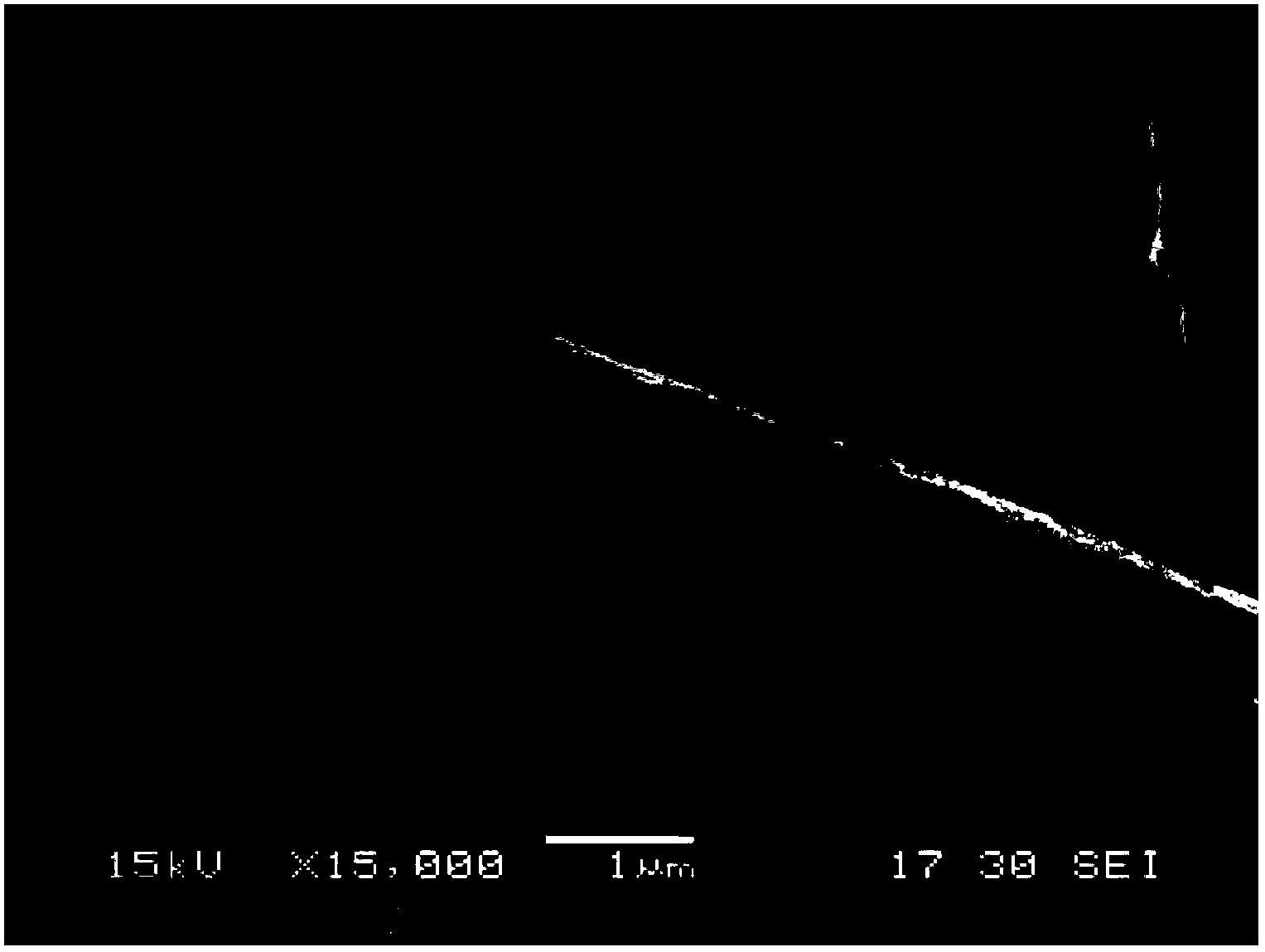

[0069] 3) Preparation of perfluorosulfonic acid / polyethersulfone nanofiber membrane

[0070] The above-mentioned organic solution is statically defoamed, and then transferred to an electrospinning device for spinning, the conditions are: power supply voltage 16kV, feed rate 0.8ml / h, adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com