High-temperature-resistant radar and infrared compatible stealth coating and preparation method thereof

A high-temperature-resistant, infrared technology, applied in coatings, devices for coating liquid on surfaces, and pre-treated surfaces, etc., can solve the problem of ensuring the uniform distribution of radar absorbers, the repeatability of microstructure, and the stability and reliability of coating quality Low performance, difficult engineering application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

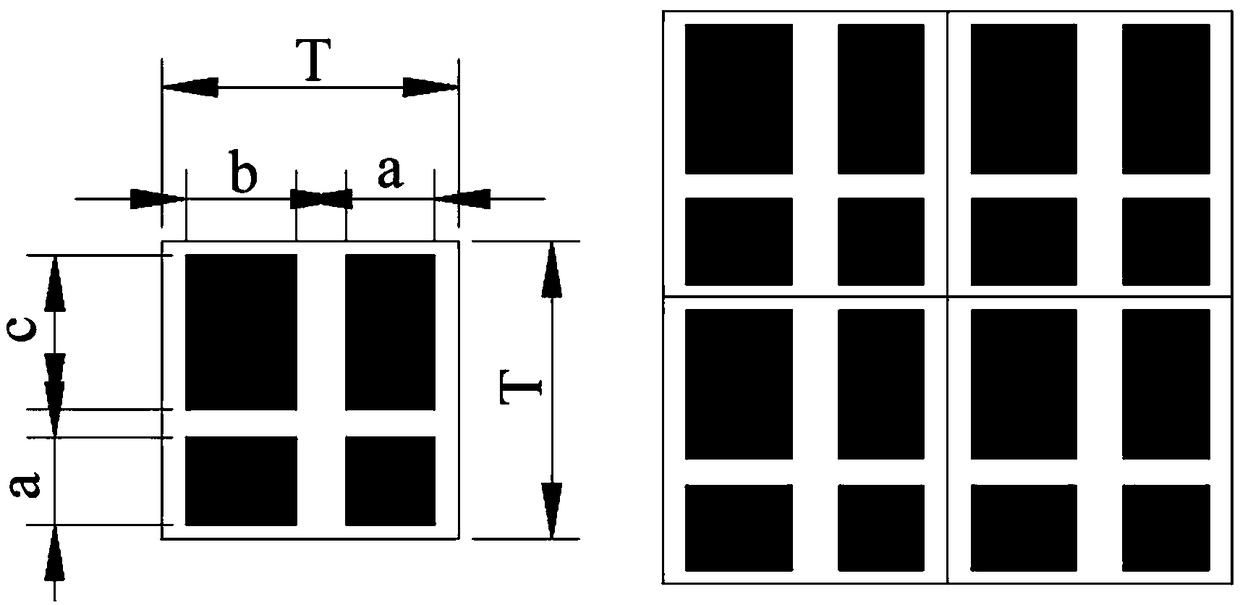

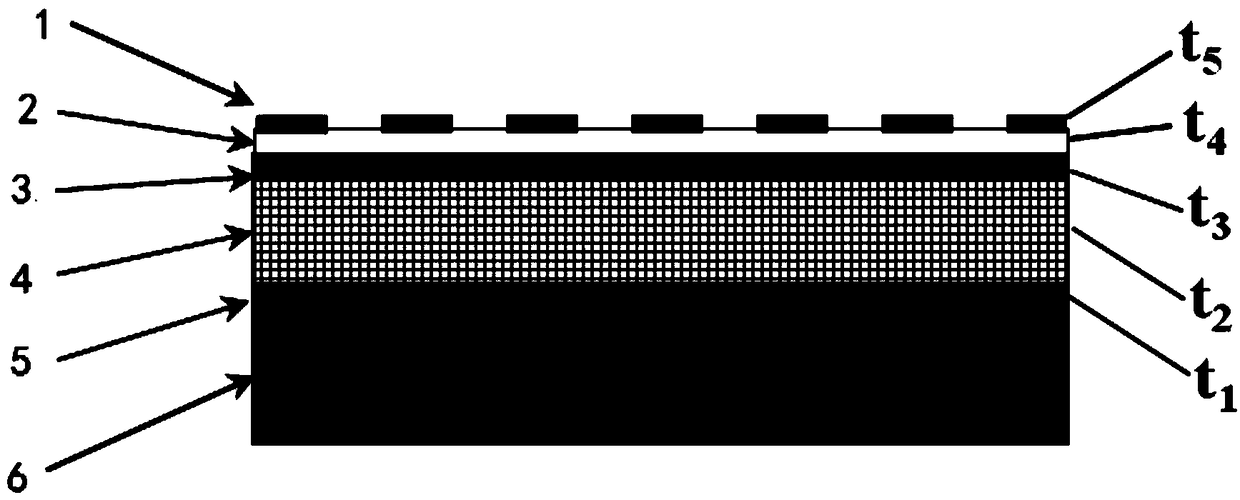

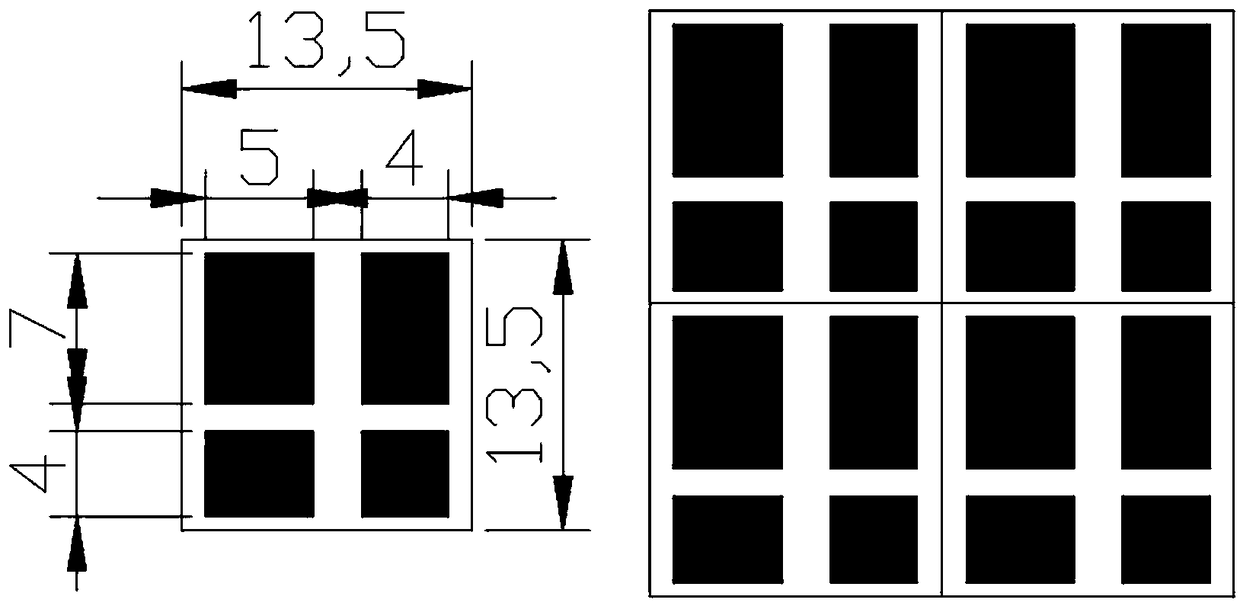

[0056] A high temperature resistant radar and infrared compatible stealth coating of the present invention, the high temperature resistant radar and infrared compatible stealth coating is located on the metal substrate 6, the high temperature resistant radar and infrared compatible stealth coating is a layered structure, such as figure 2 As shown, from the inside to the outside, it includes a metal bonding layer 5 (CoCrAlY alloy coating), a ceramic absorbing layer 4 (Al 2 o 3 - Ni-based ceramic materials, Ni and Al 2 o 3 The mass ratio is 40:60), chip resistance type high temperature periodic structure layer 3, ceramic isolation layer 2 (8YSZ ceramic material) and infrared low emissivity frequency selective surface layer 1;

[0057] The chip resistance type high temperature periodic structure layer 3 is arranged with Bi 2 o 3 -SiO 2 -B 2 o 3 It is a high-temperature resistance coating with low melting point lead-free glass as the binding phase and molybdenum disilicide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com