Variable rotating equivalent inertia mass damper

A technology of inertial mass and damper, which is applied in the field of energy dissipation and vibration reduction of engineering structures, to achieve clear functional divisions, prolong service time, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

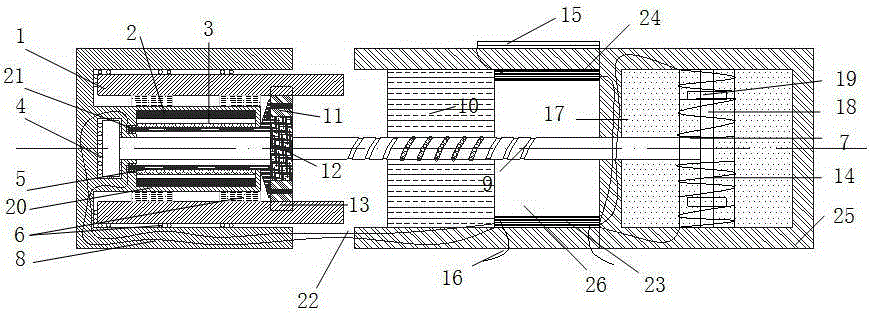

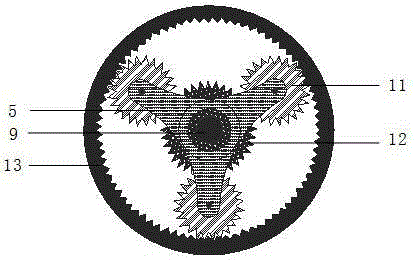

[0031] Such as Figure 1-4 As shown, the present invention is a variable rotation equivalent inertial mass damper, which includes a main energy dissipation element, a translation / rotation conversion device, a planetary gear set speed change device, a secondary energy dissipation element, a cylindrical rotating mass 1, a control Circuit, working state circuit, left sleeve 8, right sleeve 25 form. Said, translation / rotation conversion device comprises screw rod 9, ball nut 10 and thrust bearing 4;

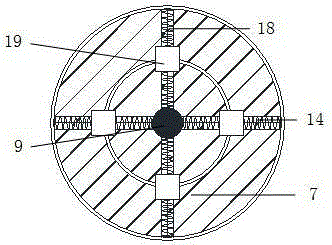

[0032] The left sleeve 8 is equipped with a planetary gear set speed change device, secondary energy-consuming elements and a cylindrical rotating mass 1; the cylindrical rotating mass 1 is fixed between the inner cylinder 20 of the left sleeve and the outer cylinder 8 of the left sleeve by a roller 6, There are tooth marks 13 in the part close to the right end, and the inner cylinder of the left sleeve is equipped with secondary energy-consuming elements, planetary gear set speed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com