Novel copolymer based on naphthalene nucleus, preparation method thereof and ternary electric storage device prepared therefrom

A storage device and copolymer technology, applied in the field of ternary electrical storage devices, can solve the problems of unclear storage mechanism and lack of functional materials, and achieve the effects of mature device fabrication process, great value and stable device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

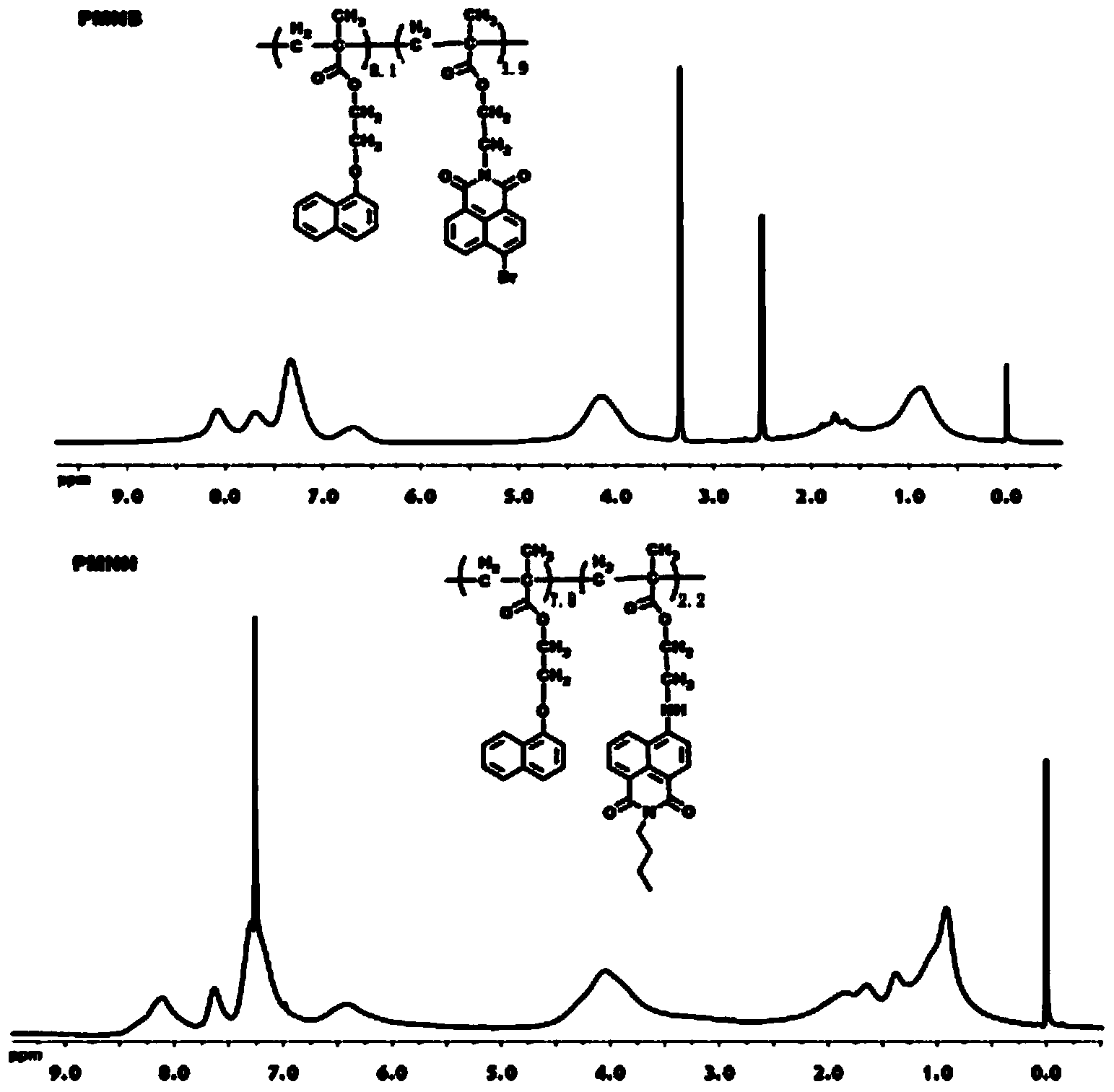

[0036] The synthesis of embodiment one and two kinds of novel copolymers PMNB and PMNN based on naphthalene ring, its synthetic steps are as follows:

[0037] (1) Synthesis of 2-(1-naphthyl ether)-ethanol:

[0038] Add 14.0g KOH, 2.88g (20mmol) of 1-naphthol, and 80ml of DMF into a 100mL round-bottom flask, react for 45min, add 2.8mL (40mmol) of 2-chloroethanol dropwise, raise the temperature to 110°C for 10h, pour into water to wash, Extracted 3 times with dichloromethane, anhydrous Na 2 SO 4 Dry and remove the solvent by rotary evaporation. The obtained product was subjected to column chromatography (petroleum ether: ethyl acetate = 10:1). Freeze at low temperature to obtain pale pink solid, yield: 90%.

[0039] 1H-NMR(DMSO,400MHz),δ(ppm):3.87(m,2H),4.16(d,J=4.49Hz,2H),4.99(s,1H),6.96(m,1H),7.36-7.56 (m,4H),7.86(d,J=6.68Hz,1H),8.26(s,1H).

[0040] (2) Synthesis of 4-bromo-N-(2-hydroxy-ethyl)-1,8-naphthalimide:

[0041] Add 2.76g (10mmol) 4-bromo-1,8-naphthalene anhyd...

Embodiment 2

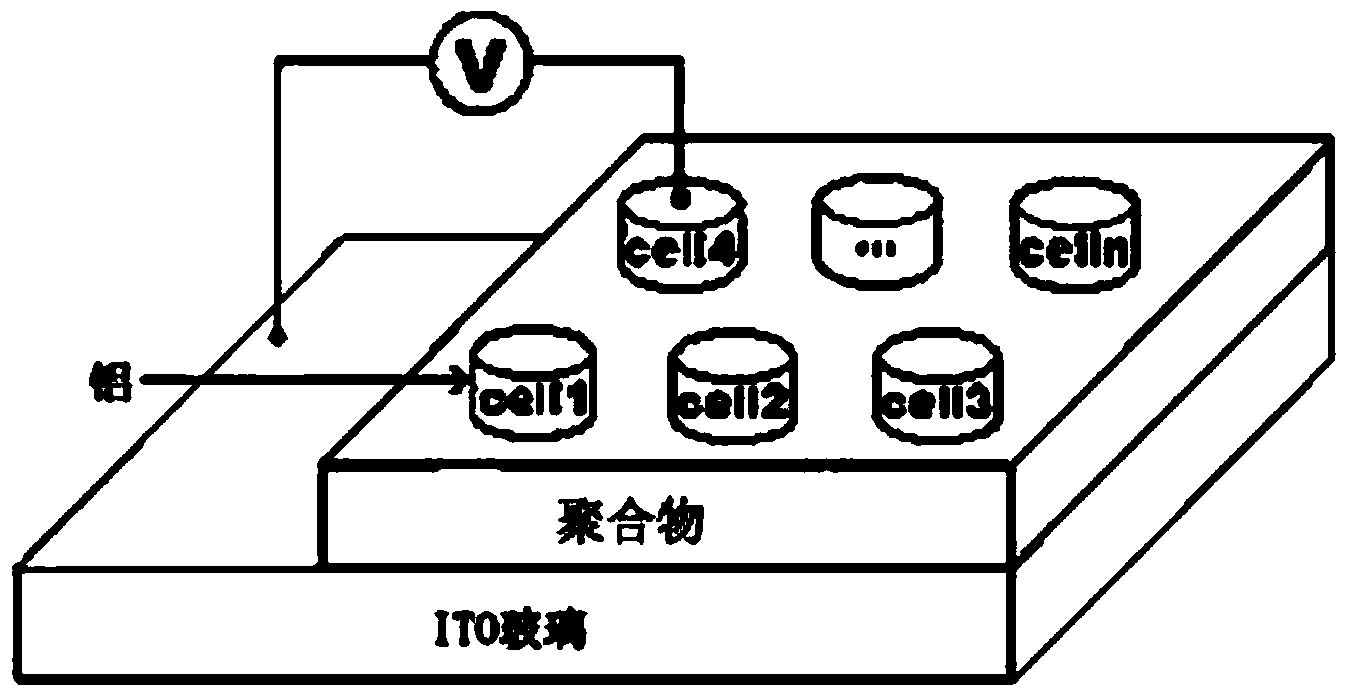

[0057] Taking the polymer PMNB obtained in Example 1 as an electrical storage active material as an example, an electrical storage device with a sandwich structure was prepared, and the manufacturing procedure was as follows: the ITO conductive glass was cleaned with water, acetone, and isopropanol in ultrasonic waves for 10 to 30 minutes, respectively. , blow dry as the organic material deposition substrate and place it in a spin-coating apparatus; take 10-15 mg of polymer and dissolve it in re-distilled cyclohexanone, and spin-coat it at 2000 rpm in an air environment. After completion, put the device into Remove the solvent in a vacuum oven at 40°C. We can control the thickness of the organic film between 40 and 150 nm through the concentration of the polymer solution and the rotational speed of the spin coating; For the metal mask, hang a certain amount of aluminum wire on the tungsten wire of the vacuum coating machine, and then vacuum again until the vacuum degree in the ...

Embodiment 3

[0059] Figure 4 It represents the current flowing through the device when a continuous voltage is applied between the upper and lower electrodes for scanning. When a continuous voltage from 0 to –6.0V is applied to a point on the device, the current through the device is around –2.0V and –3.5 There are two instantaneous jumps around V, indicating that the device has gone through a transition from a low conduction state ("0" or OFF state) to an intermediate conduction state ("1" or ON1 state) to a high conduction state ("2" or ON2 state) transition (first scan). For PMNN, in the subsequent scan from 0 to -6.0V, the memory cell still maintains its high conduction state (second scan). The third scan is a 0 to –2.5V scan of another memory cell with a threshold voltage of –2.0V. In subsequent scans from 0 to –2.0V, the cell remains in an intermediate conduction state (“1”) even after power is turned off (fourth scan), when the voltage continues to increase to –6.0V, around –3.2V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com