Package structure of micro LED display module

A display module and packaging structure technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problem that the resolution of the display screen cannot be further improved, and achieve the effect of improving color stability, improving display resolution, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

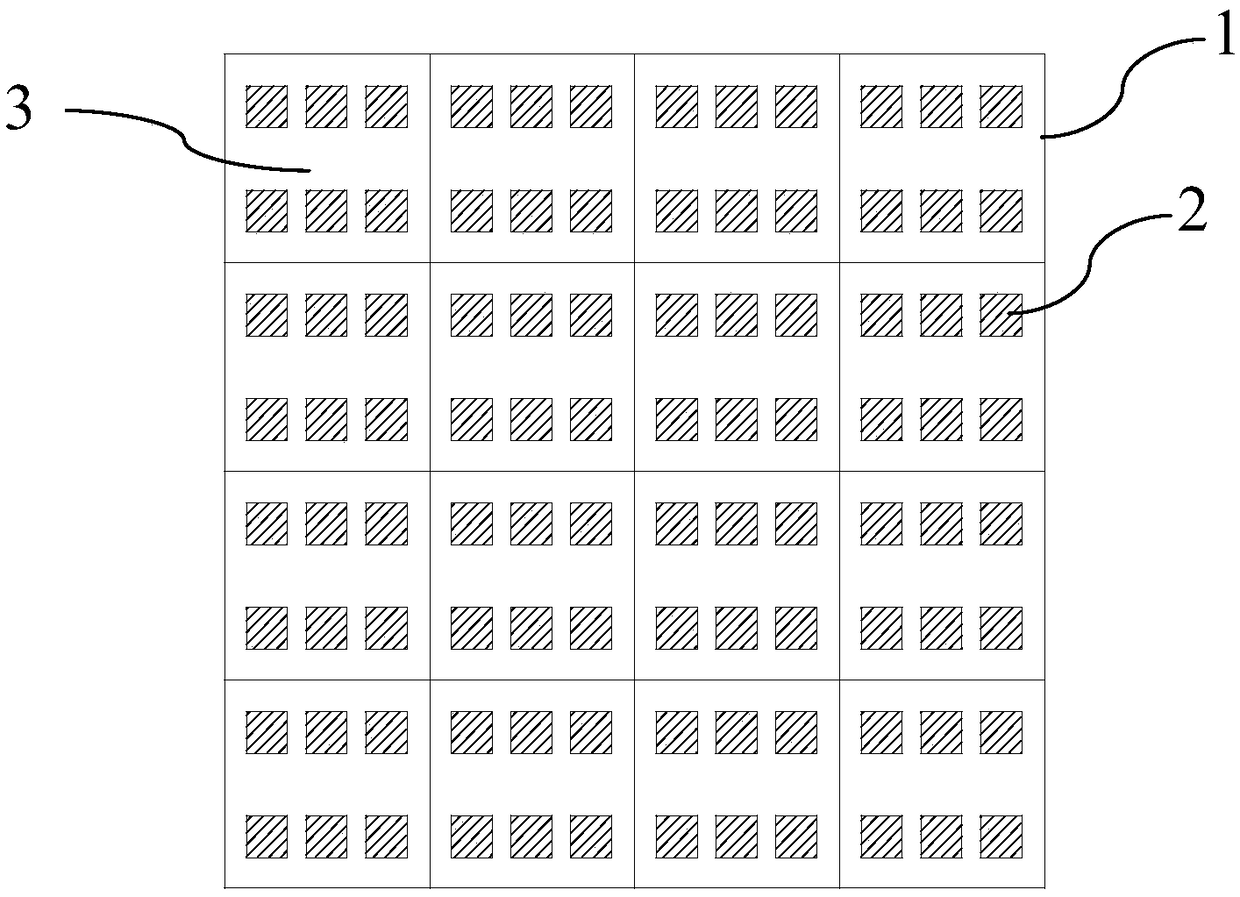

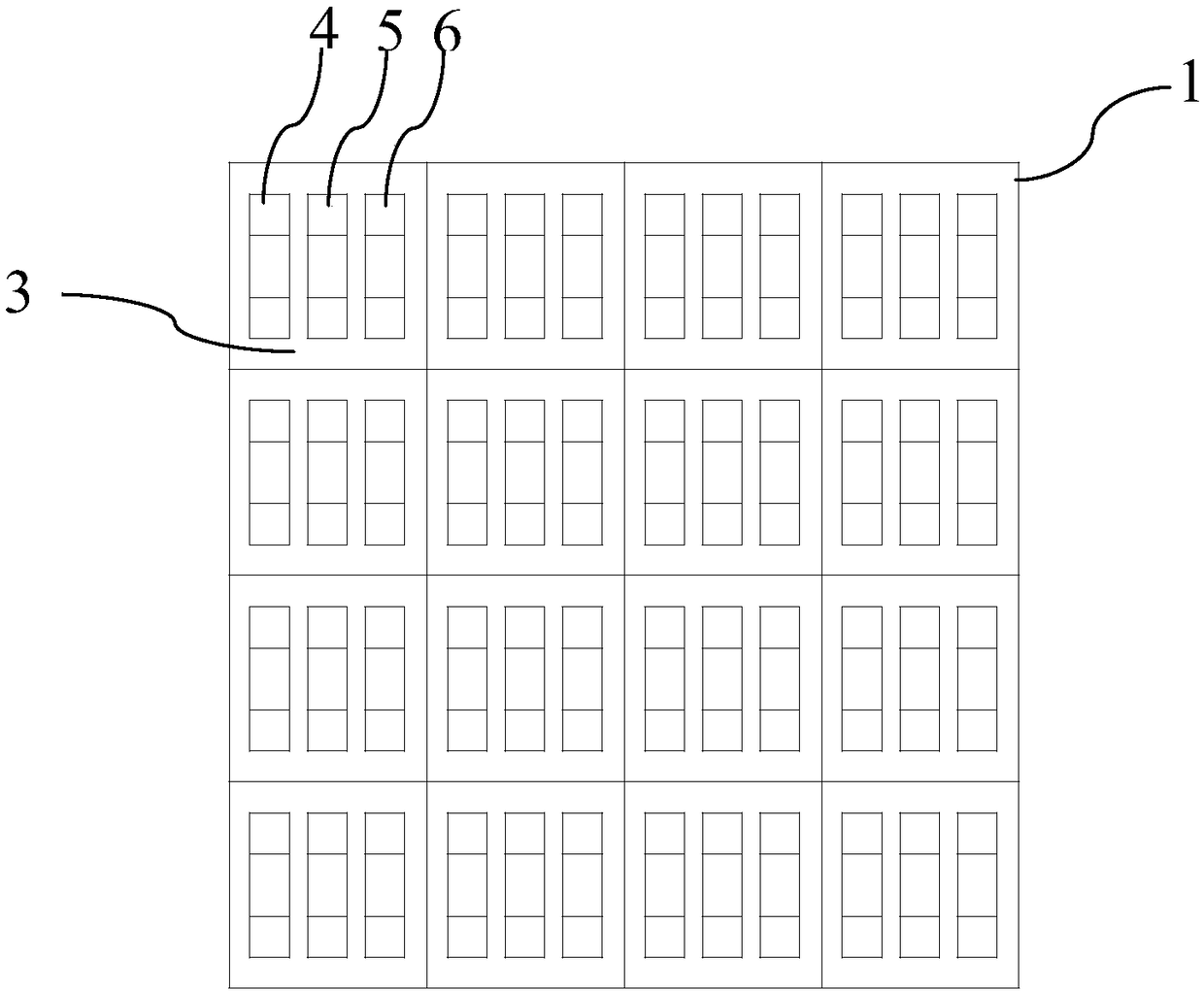

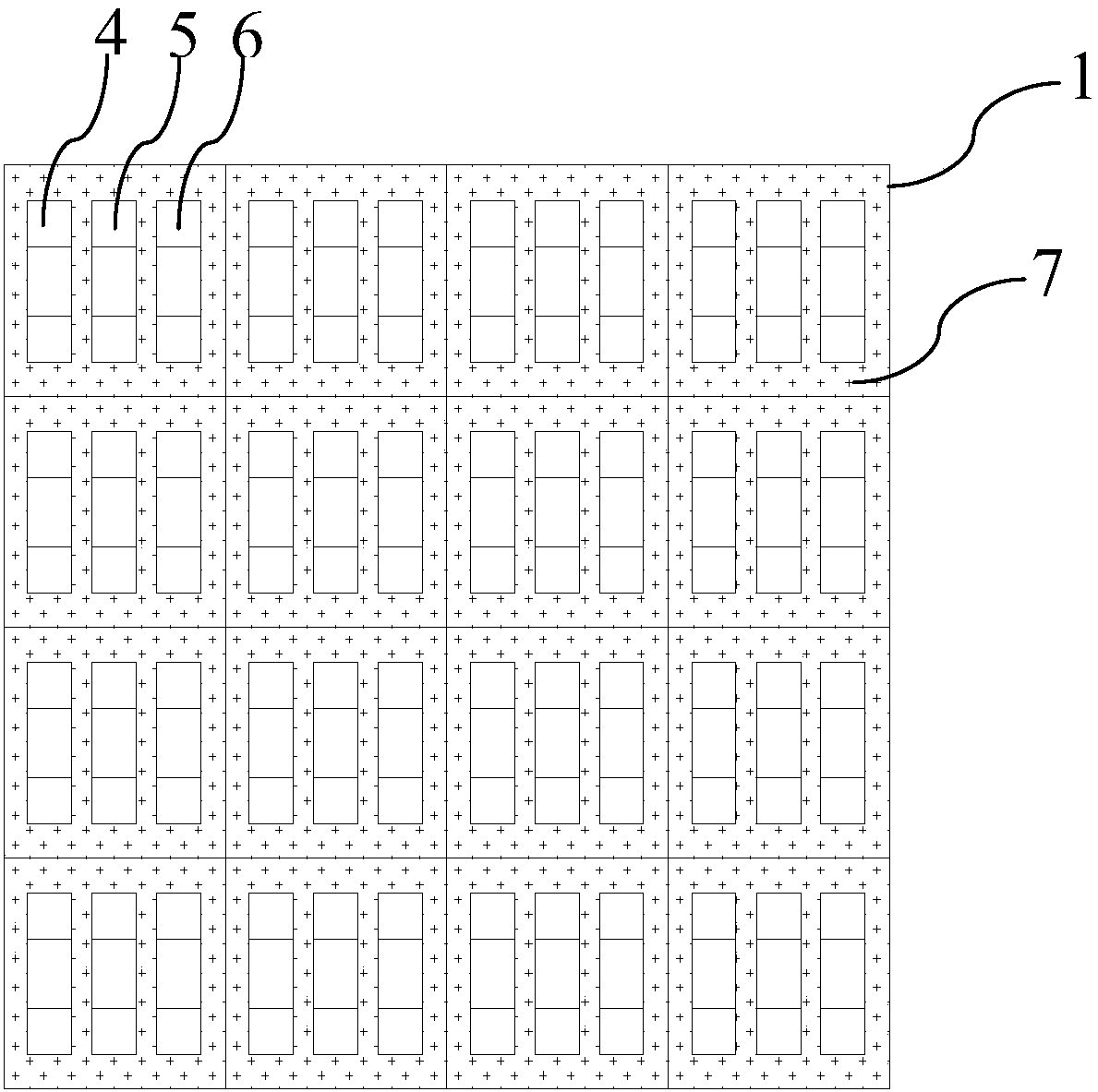

[0024] Such as figure 1 Prepare display module circuit board 1, figure 2 The first flip-chip blue light chip 4, the flip-chip green light chip 5, and the second flip-chip blue light chip 6 are fixed to the corresponding electrodes of the circuit board by flip-chip technology, image 3 The filling layer 7 is used to fill the gap between the chips, Figure 4 A red fluorescent layer 8 is coated on the surface of the second flip-chip blue light chip 6, so that after the blue light chip emits light, it is excited by the red fluorescent layer to fully absorb and emit red light. Figure 5 The entire surface of the module is encapsulated with a transparent encapsulation layer to protect the internal structure of the module and complete the encapsulation of a micro LED display module.

[0025] Image 6 It is a schematic cross-sectional view of an LED d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com