Application of graphene composite material electromagnetic shielding material

A technology of electromagnetic shielding materials and composite materials, which is applied in the application field of graphene composite materials as electromagnetic shielding materials, can solve the problems of reducing the mechanical properties and processing properties of composite materials, increasing the weight and cost of materials, and achieves excellent electromagnetic shielding performance, Improved service life, good flexibility and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, the porosity is 110PPI, the thickness is 1.9mm, and the density is 30mg / cm 3 The polyurethane sponge is immersed in the aqueous solution of sodium lauryl sulfate with a concentration of 10 mg / mL, and soaked for 10 minutes.

[0036] The soaked foam sponge sample was taken out and put into an oven at 100°C for drying and curing, and the time was set for 30 minutes.

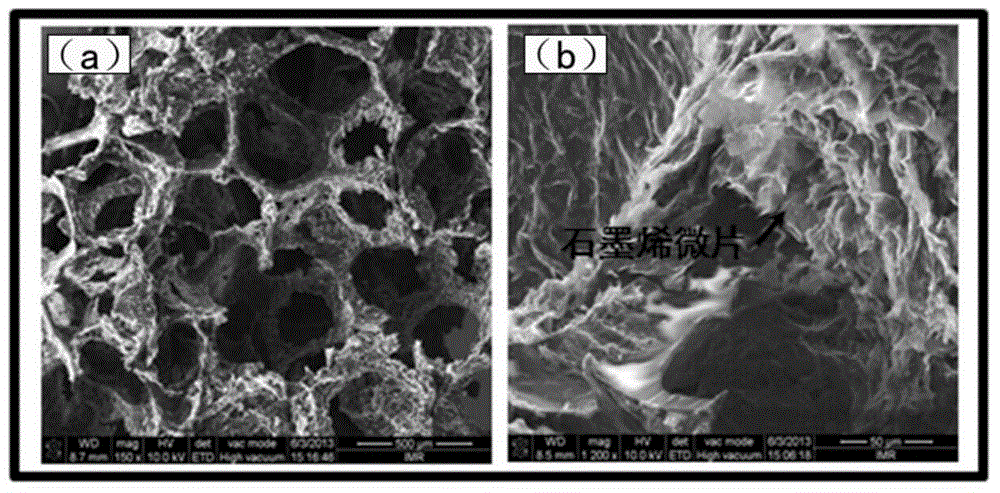

[0037] Immerse the dried foam sponge into an aqueous solution of 0.8% of the intercalation graphene content evenly dispersed as a dispersant with 1% carboxymethylcellulose sodium as a dispersant, utilize an iron roller to squeeze the foam sponge, and remove The air in the foam sponge, after soaking for 10 minutes, take it out and put it in an oven to dry and solidify at 120°C, and the time is set for 30 minutes.

[0038] Immerse the dried material again in an aqueous solution of 0.8% intercalation graphene content of evenly dispersed intercalated graphene as a dispersant with 1% sodium carboxymethyl c...

Embodiment 2

[0044] First, the porosity is 110PPI, the thickness is 1.9mm, and the density is 30mg / cm 3 The polyurethane sponge is immersed in the aqueous solution of sodium lauryl sulfate with a concentration of 10 mg / mL, and soaked for 10 minutes.

[0045] The soaked foam sponge sample was taken out and put into an oven at 100°C for drying and curing, and the time was set for 30 minutes.

[0046] Immerse the dried foam sponge into an aqueous solution of 0.8% of the intercalation graphene content evenly dispersed as a dispersant with 1% carboxymethylcellulose sodium as a dispersant, utilize an iron roller to squeeze the foam sponge, and remove The air in the foam sponge, after soaking for 10 minutes, take it out and put it in an oven to dry and solidify at 120°C, and the time is set for 30 minutes.

[0047] Immerse the dried material again in an aqueous solution of 0.8% intercalation graphene content of evenly dispersed intercalated graphene as a dispersant with 1% sodium carboxymethyl c...

Embodiment 3

[0050] First, the porosity is 200PPI, the thickness is 1.9mm, and the density is 30mg / cm 3 The polyurethane sponge is immersed in the aqueous solution of sodium lauryl sulfate with a concentration of 10 mg / mL, and soaked for 10 minutes.

[0051] The soaked foam sponge sample was taken out and put into an oven at 100°C for drying and curing, and the time was set for 30 minutes.

[0052] Immerse the dried foam sponge into an aqueous solution of 0.8% of the intercalation graphene content evenly dispersed as a dispersant with 1% carboxymethylcellulose sodium as a dispersant, utilize an iron roller to squeeze the foam sponge, and remove The air in the foam sponge, after soaking for 10 minutes, take it out and put it in an oven to dry and solidify at 120°C, and the time is set for 30 minutes.

[0053] Immerse the dried material again in an aqueous solution of 0.8% intercalation graphene content of evenly dispersed intercalated graphene as a dispersant with 1% sodium carboxymethyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding performance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Electromagnetic shielding performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com