Microwave determination method for breakable beads in breakable bead filter rod

A technology of explosive beads and filter rods, which is applied in the directions of using microwave flaw detection, electromagnetic wave detection, and material analysis using microwave means, which can solve the problem that the position offset of the explosive beads cannot be completed at the same time, and achieve accurate measurement and accurate measurement results. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Collect 20 samples of popping beads and measure the diameter of the popping beads D b = 2.59 mm.

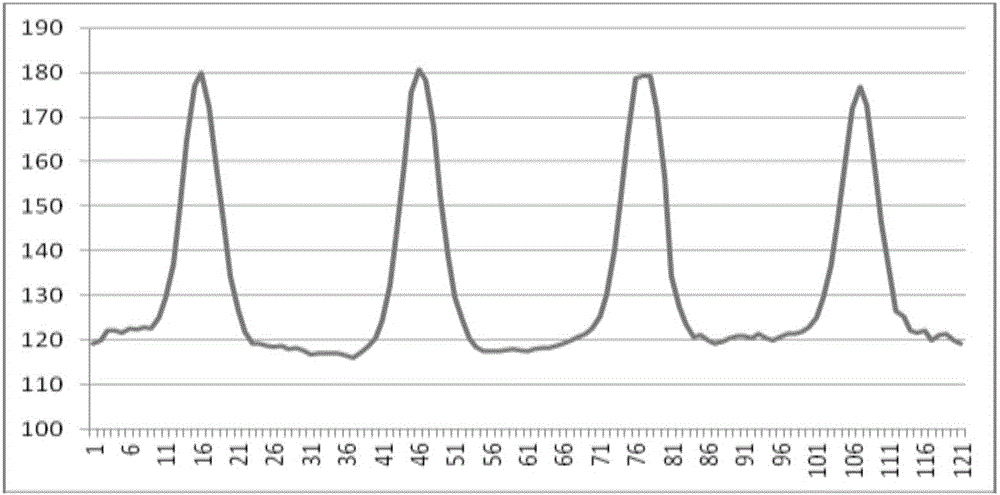

[0036] Collect 20 beads filter rod samples, and measure the density ρ of the part of the filter rod that does not contain beads l =120.22 mg / cm 3 , the maximum value ρ lmax =126.7 mg / cm 3 ;Measure the minimum value ρ of the density of the part of the filter rod containing explosive beads bmin =172.56 mg / cm 3 ;Taking the length of 1mm as the measurement unit, use the microwave resonance method to measure the density of the blasting bead filter rod. Measure the density of the blasting bead filter rod. Take the measurement unit as the unit, take the length as the horizontal axis, and take the density as the vertical axis to draw the density curve of the blasting bead filter rod ,like figure 1 shown.

[0037] Find the first maximum value M on the density curve according to the design number of popping beads 4 1 =180.8 mg / cm 3 with L 1 =46, M 2 =180.1 mg / cm 3 with L...

Embodiment 2

[0040] Collect 20 samples of popping beads and measure the diameter of the popping beads D b = 2.62 mm.

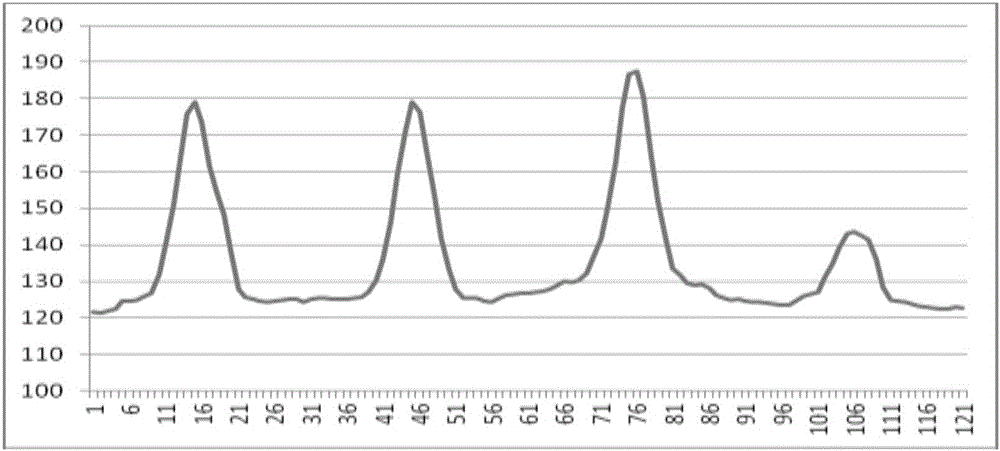

[0041] Collect 20 beads filter rod samples, and measure the density ρ of the part of the filter rod that does not contain beads l =125.11 mg / cm 3 , the maximum value ρ lmax =127.80 mg / cm 3 ;Measure the minimum value ρ of the density of the part of the filter rod containing explosive beads bmin =178.88 mg / cm 3 ;Taking the length of 1mm as the measurement unit, use the microwave resonance method to measure the density of the blasting bead filter rod. Measure the density of the blasting bead filter rod. Take the measurement unit as the unit, take the length as the horizontal axis, and take the density as the vertical axis to draw the density curve of the blasting bead filter rod ,like figure 2 shown.

[0042] Find the first maximum value M on the density curve according to the design number of popping beads 4 1 =187.6 mg / cm 3 with L 1 =76, M 2 =179.1 mg / cm 3 with...

Embodiment 3

[0045] Collect 20 samples of popping beads and measure the diameter of the popping beads D b = 2.60 mm.

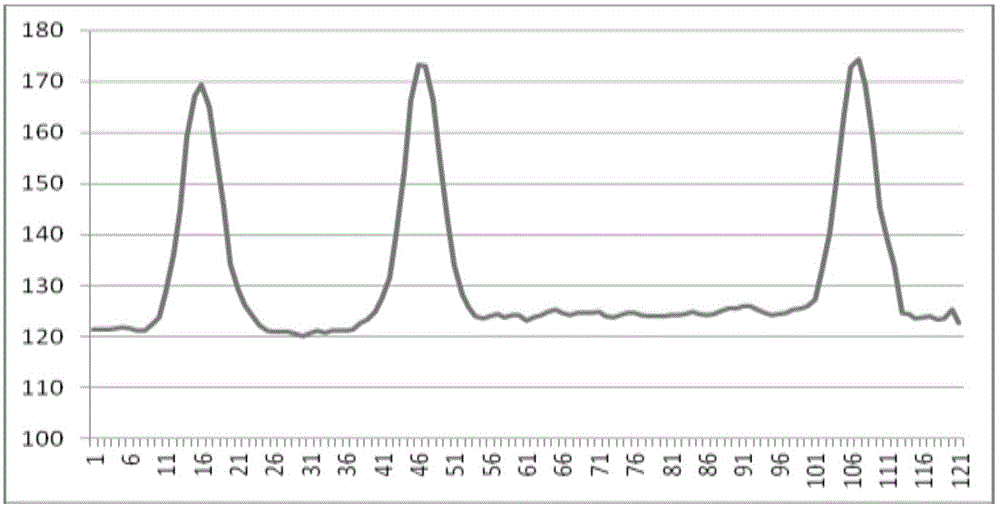

[0046] Collect 20 beads filter rod samples, and measure the density ρ of the part of the filter rod that does not contain beads l =123.64 mg / cm 3 , the maximum value ρ lmax =128.80 mg / cm 3 ;Measure the minimum value ρ of the density of the part of the filter rod containing explosive beads bmin =168.52 mg / cm 3 ;Taking the length of 1mm as the measurement unit, use the microwave resonance method to measure the density of the blasting bead filter rod. Measure the density of the blasting bead filter rod. Take the measurement unit as the unit, take the length as the horizontal axis, and take the density as the vertical axis to draw the density curve of the blasting bead filter rod ,like image 3 shown.

[0047] Find the first maximum value M on the density curve according to the design number of popping beads 4 1 =174.3 mg / cm 3 with L 1 =107, M 2 =173.2 mg / cm 3 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com