Greenhouse cultivated vegetable harvesting mechanical device

A mechanical device, greenhouse cultivation technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor input and production cost, unfavorable for large-scale planting production, low productivity, etc., and reduce labor input. and production costs, is conducive to organizing large-scale planting production, and overcomes the effect of labor-intensive operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

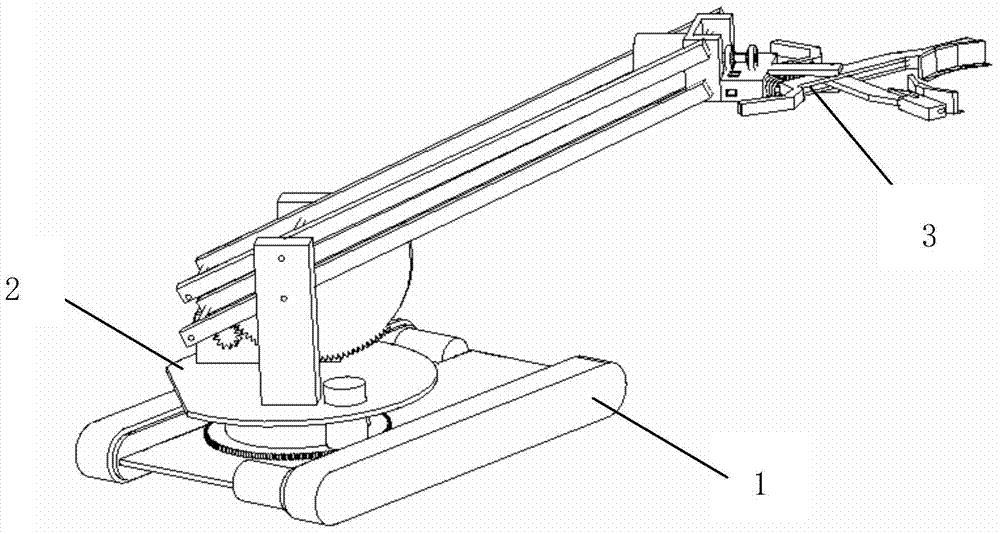

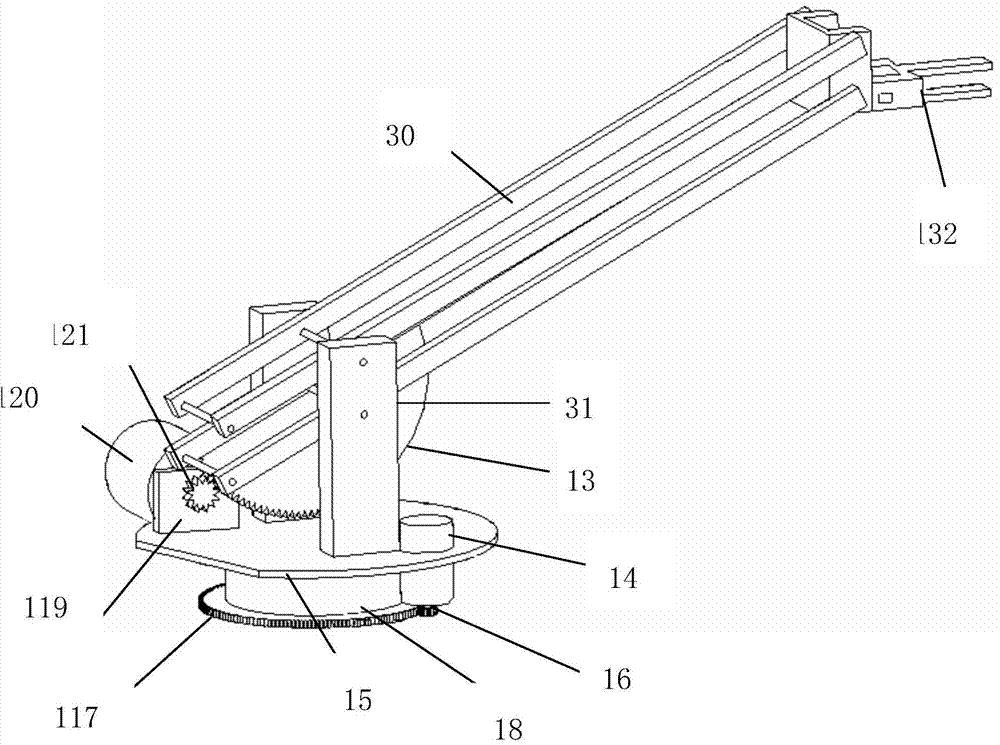

[0017] Such as figure 1 As shown, a mechanical device for harvesting vegetables grown in greenhouses includes a driving mechanism 1, a rotating platform 2, and a harvesting manipulator 3. The rotating platform 2 is arranged on the driving mechanism 1, and the harvesting manipulator 3 is connected to the rotating platform 2;

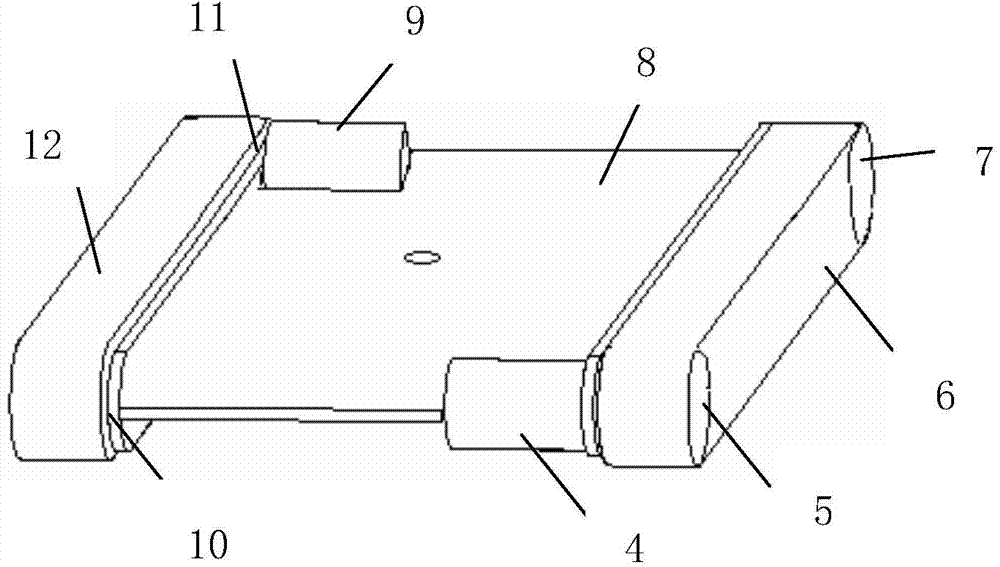

[0018] Such as figure 2 As shown, the driving mechanism 1 includes: a front wheel driving motor 4, a right front driving wheel 5, a right timing belt 6, a right rear wheel 7, a supporting plate 8, a rear wheel driving motor 9, a left front wheel 10, and a left rear driving wheel 11 and the left timing belt 12.

[0019] The front wheel drive motor 4 and the rear wheel drive motor 9 are respectively fixed on the diagonally opposite corners of the bottom surface of the support plate. The right front drive wheel 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com