Microwave hot-pressing sintering and brazing device and using method thereof

A technology of hot pressing sintering and microwave generating device, which is applied in the field of mechanical equipment, can solve the problems of low diffusivity, application, and difficulty in realizing microwave heating equipment, and achieve low dielectric constant, increased density, and reduced microwave leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

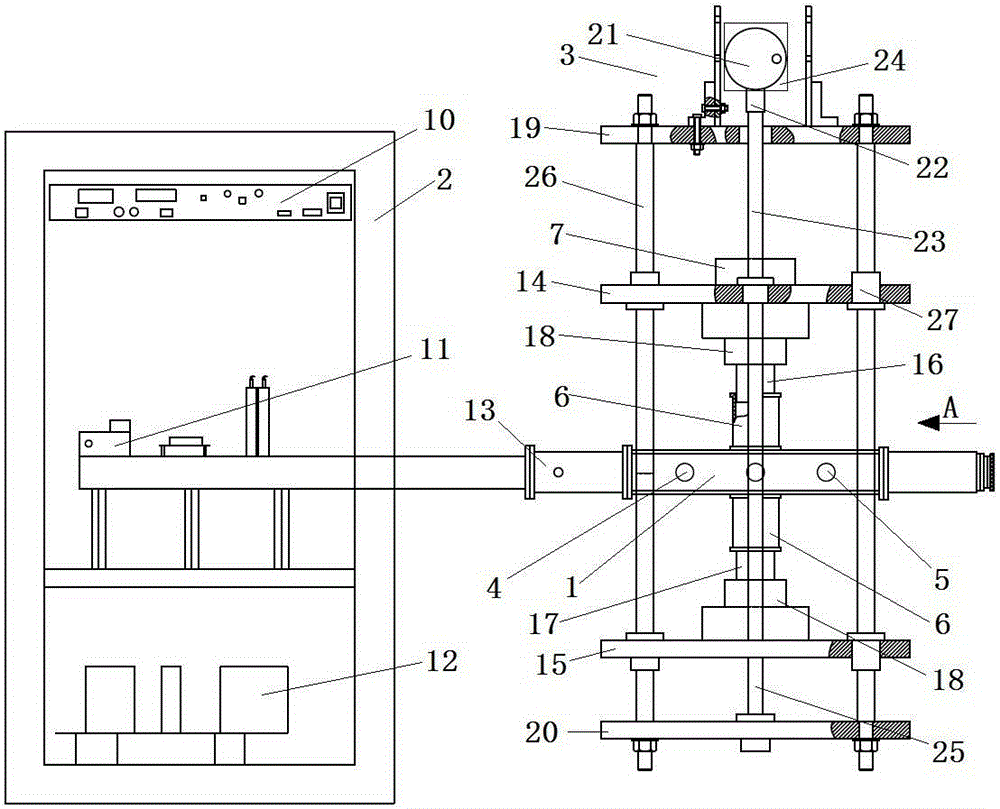

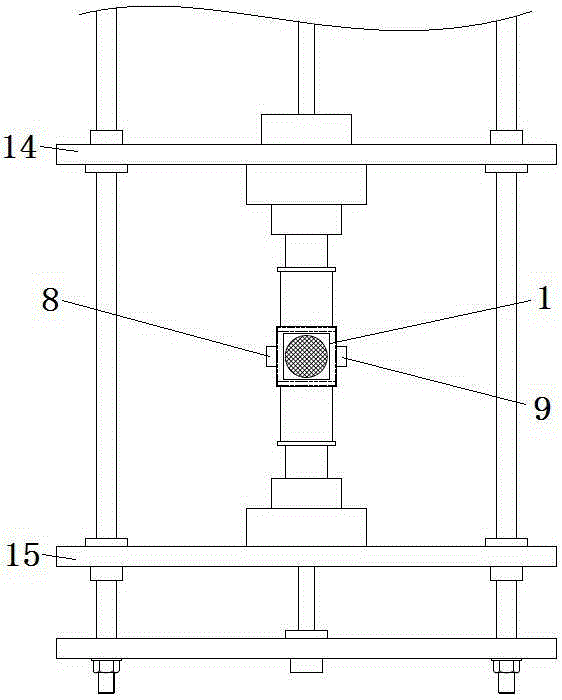

[0031] Such as Figure 1~2 As shown, a microwave hot pressing sintering and brazing device includes a microwave resonant cavity 1, a microwave generating device 2 is connected to one side of the microwave resonant cavity, and an adjustable total reflection terminal device is connected to the other side. A pressurization system 3 for applying pressure to the sample is also arranged on the microwave resonant cavity.

[0032] In this embodiment, the microwave resonant cavity is a sandwich water-cooled rectangular structure, and the outer wall of the microwave resonant cavity is provided with a cooling water inlet 4 and a cooling water outlet 5 .

[0033] In this embodiment, the front, rear, top, and bottom of the microwave resonant cavity are respectively provided with a cylindrical attenuation waveguide 6 communicating with the interior to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com