Konjak elastic jelly gel soap and preparation method thereof

An elastic and jelly technology, applied in the direction of chemical instruments and methods, surface active detergent compositions, detergent composition spices, etc., can solve the problem that the measurement of viscosity and hardness cannot be realized at the same time, the sol-gel state does not exist, storage and Harsh transportation conditions and other issues, to achieve the effect of increasing water retention and gel performance, suitable gel strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

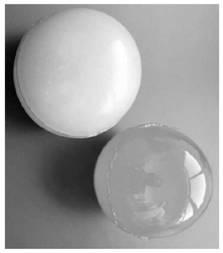

Image

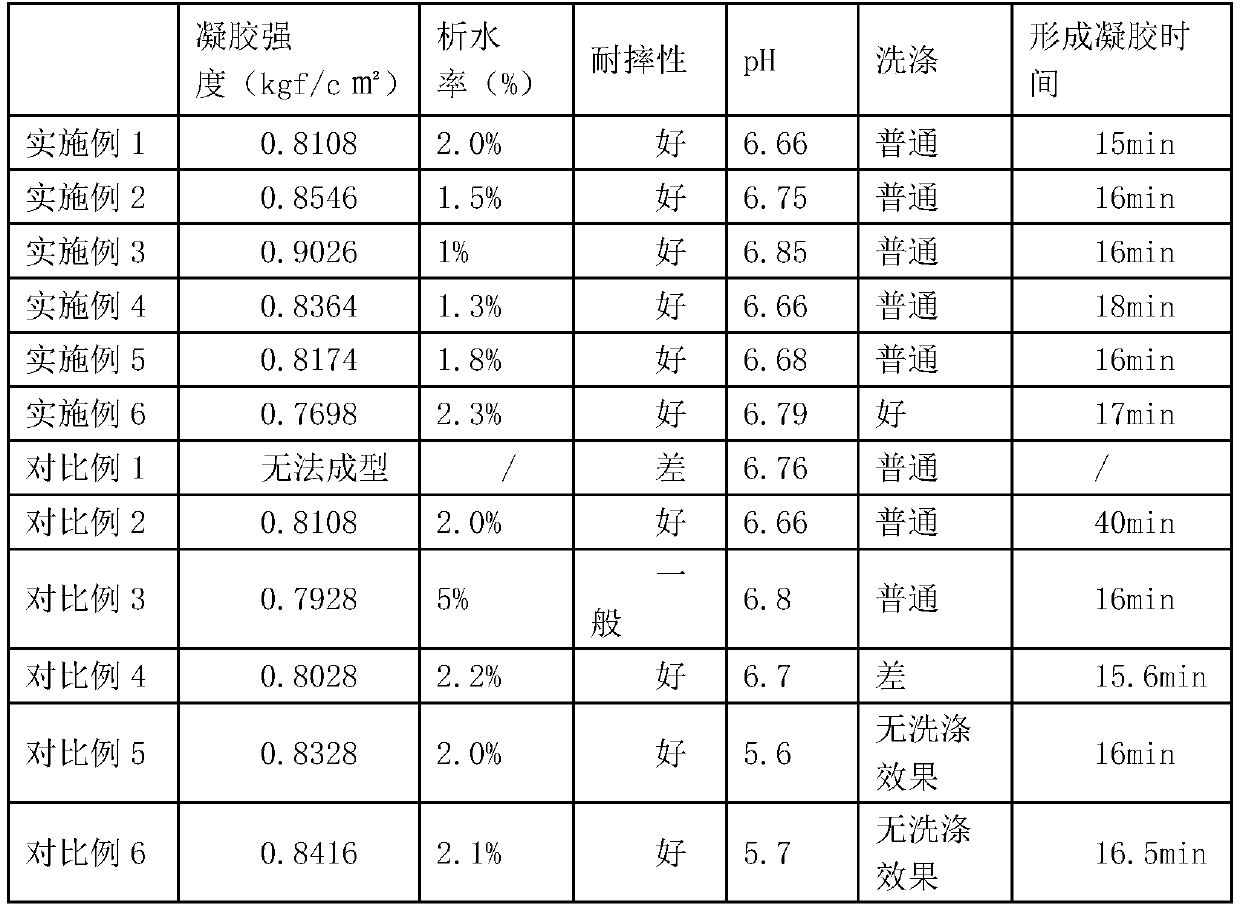

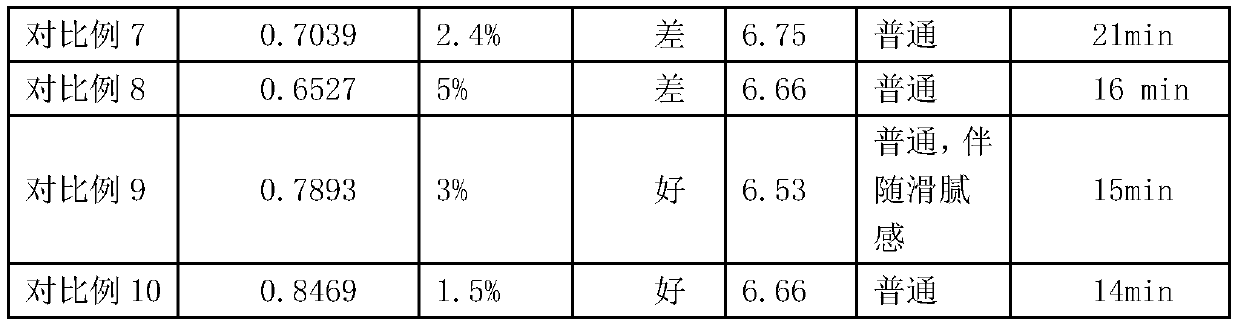

Examples

Embodiment 1

[0047] A kind of konjac elastic jelly gel soap, comprising the following raw material components by mass fraction: tamarind seed gum 2%, curdlan gum 1%, konjac flour 1%, sucrose 8%, linseed gum 0.5%, citric acid 0.8 %, glycerin 8%, butanediol 2%, capryl glucoside 5%, lauryl glucoside 10%, centella asiatica extract 1%, essence 0.01%, pigment 0.03%, water balance.

[0048] The viscosity of the konjac flour is 1000mPa.s.

[0049] The preparation method of described konjac elastic jelly gel soap, described method comprises the following steps:

[0050] S1: Mix tamarind gum, curdlan gum, konjac flour, linseed gum, citric acid, and sucrose evenly to obtain a mixed powder, weigh the glycerin and butanediol in the above proportions and mix to obtain a mixed solution;

[0051] S2: Put the above mixed solution in a vacuum stirring tank, add the above mixed powder under stirring state, stir until it is completely dispersed, then add water to obtain a mixed glue;

[0052] S3: Stir the w...

Embodiment 2

[0060] A konjac elastic jelly gel soap comprises the following raw material components by mass fraction: 4% tamarind gum, 2% curdlan gum, 2% konjac flour, 8% sucrose, 1% linseed gum, 0.8% citric acid , Glycerin 8%, Butylene Glycol 2%, Capryl Glucoside 5%, Lauryl Glucoside 10%, Centella Asiatica Extract 1%, Flavor 0.01%, Pigment 0.03%, Water balance. Others are the same as embodiment 1.

Embodiment 3

[0062] A konjac elastic jelly gel soap comprises the following raw material components by mass fraction: tamarind gum 7%, curdlan gum 3%, konjac flour 3%, sucrose 8%, linseed gum 1%, citric acid 0.8% , Glycerin 8%, Butylene Glycol 2%, Capryl Glucoside 5%, Lauryl Glucoside 10%, Centella Asiatica Extract 1%, Flavor 0.01%, Pigment 0.03%, Water balance. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com