System for visualizing the cavity-inside microwave ignition and combustion process

A technology of microwave ignition and combustion process, applied in the fields of microwave combustion support and microwave ignition, to achieve the effect of improving fuel utilization rate and combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

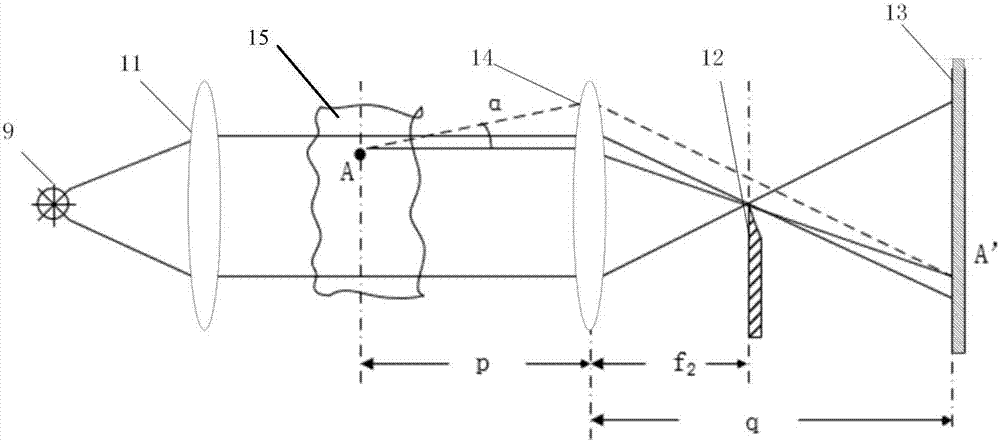

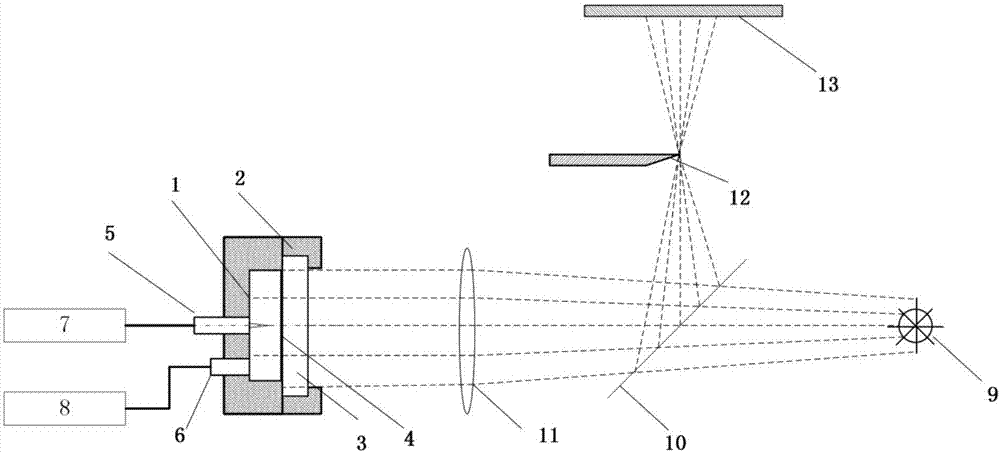

[0017] A further description of the visualization observation system for realizing the microwave ignition and combustion process in the cavity proposed by the present invention is as follows with reference to the accompanying drawings.

[0018] A schematic diagram of the structure of a system for realizing the visual observation of microwave ignition and combustion process in the cavity proposed by the present invention can be found in figure 2 , the system includes two parts: a microwave ignition device and a microwave ignition visualization device;

[0019] The microwave ignition device includes a U-shaped upper end cover 1, a flat lower end cover 2 with an opening in the middle, quartz glass 3, a microwave coupler 5, a microwave source generator 7, a gas distribution circuit valve 6 and a gas distribution circuit 8; wherein, The upper end cover 1 and the lower end cover 2 are compressed and fixed to form a microwave combustion chamber. The inner side of the top end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com