Disinfection well for ultraviolet sewage treatment by using microwaves

A technology of sewage treatment and ultraviolet light, applied in the direction of light water/sewage treatment, etc., can solve the problems of large area, high cost, short maintenance cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

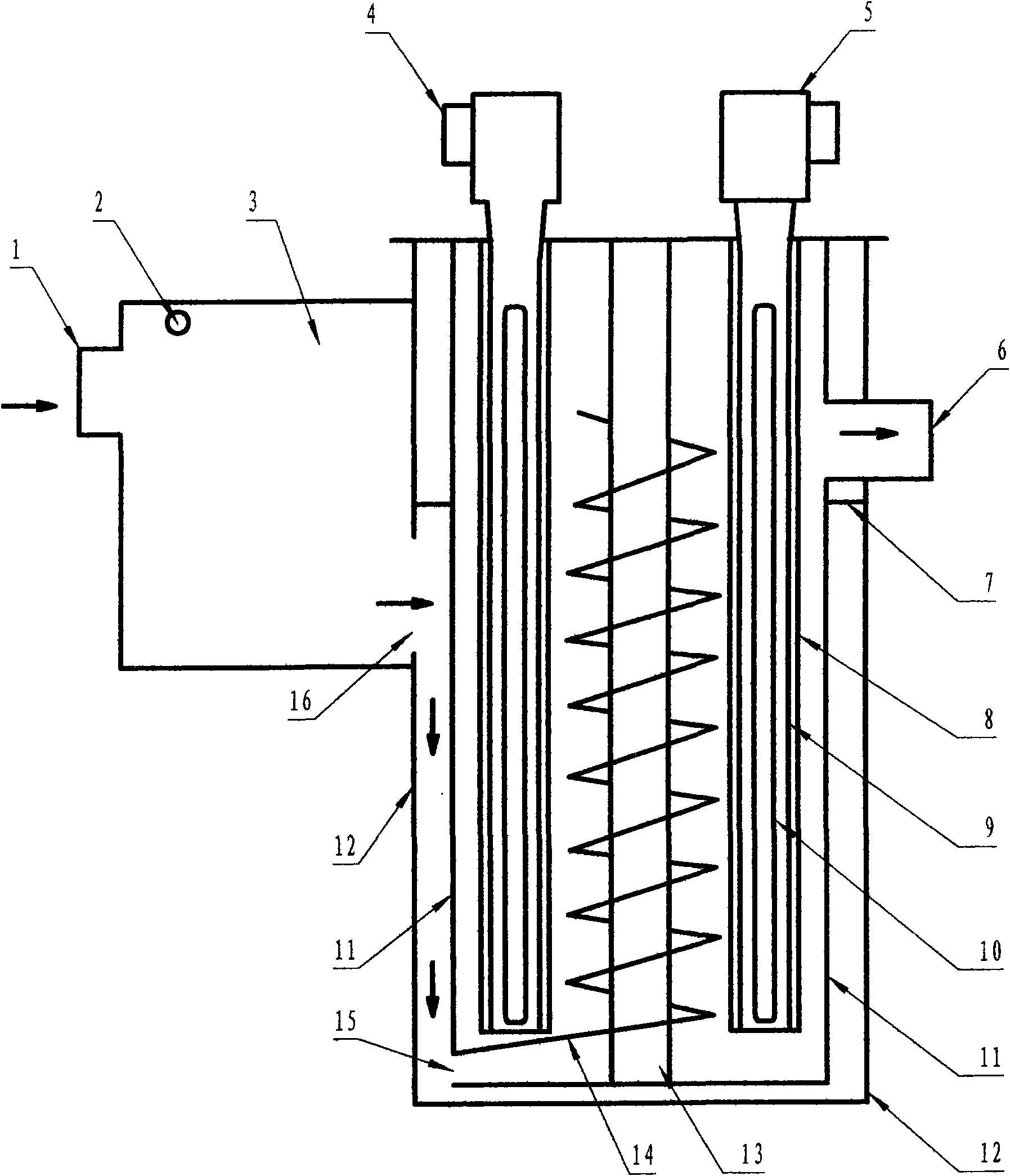

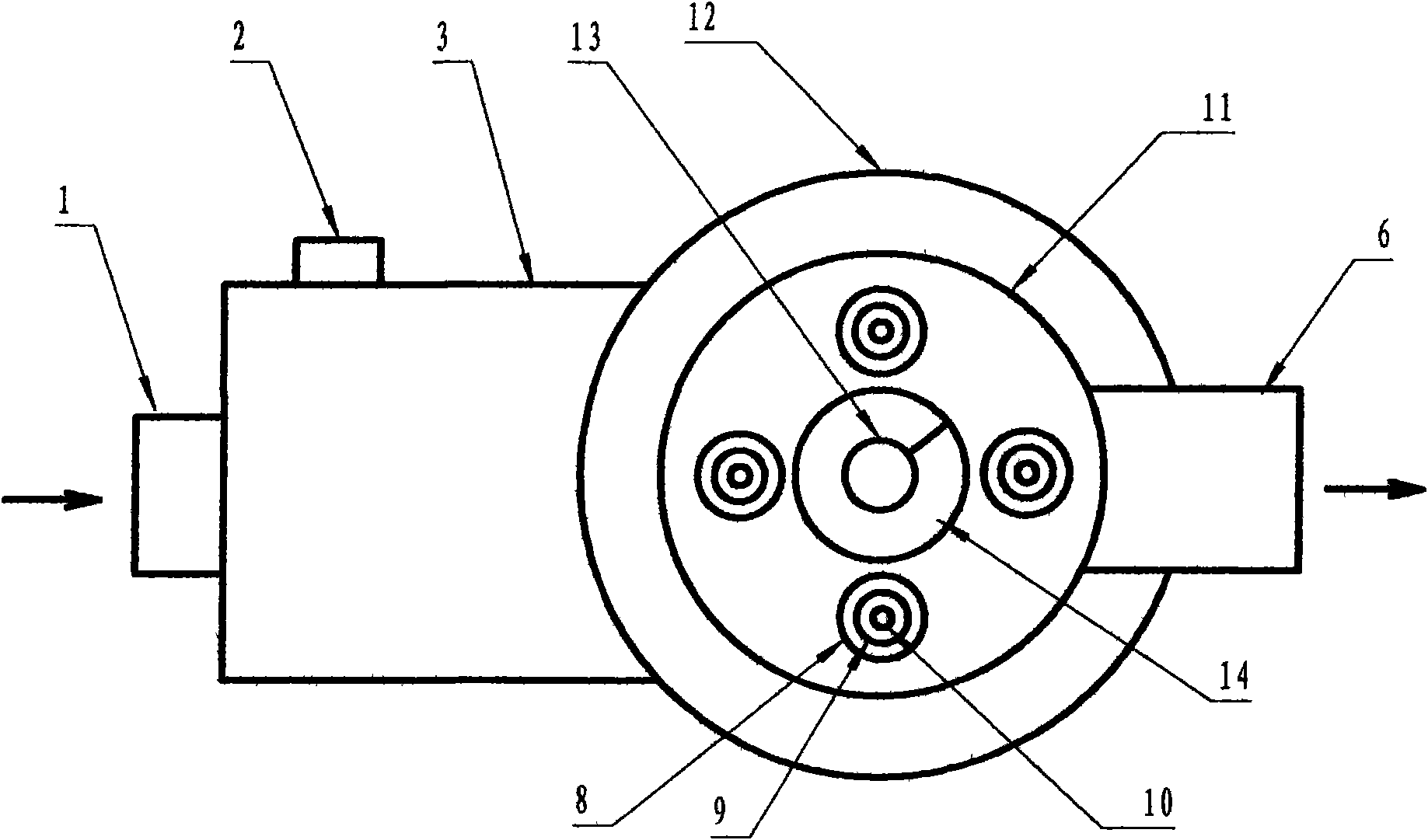

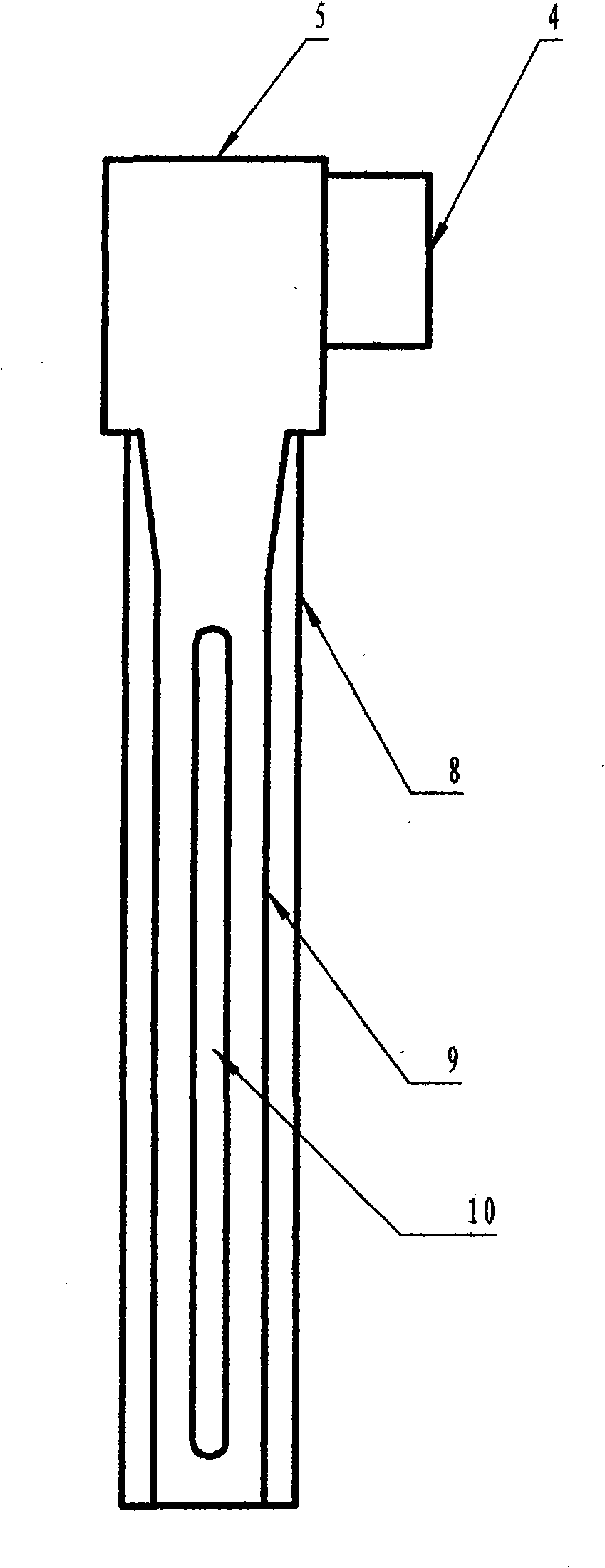

[0008] Water flows into the balance pool 3 from the inlet 1. The balance pool has a certain water storage capacity, and the short-term overcurrent can be relieved in the balance pool. When the water inflow exceeds the rated flow for a long time, it can overflow from the overflow port 2 to reach balance. The purpose of water flow, the level difference in the balance pond is higher than the height difference that water outlet 6 produces makes water flow out smoothly. 16 is a diversion port, and the water in the balance pool flows into between the well wall 12 and the outer cylinder 11 of the ultraviolet sterilizer from this mouth, and then flows into the outer cylinder 11 of the ultraviolet sterilizer from the spiral diversion inlet 15 at the bottom. It rises along the spiral guide partition 14 installed around the column 13 and is discharged from the outlet 6. These devices can prolong the contact time between water and ultraviolet rays, and also can make water fully irradiated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com