Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

A high-entropy alloy and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve problems such as segregation, inability to improve forming quality, and poor surface forming quality, and achieve high hardness, process repeatability and The effect of improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

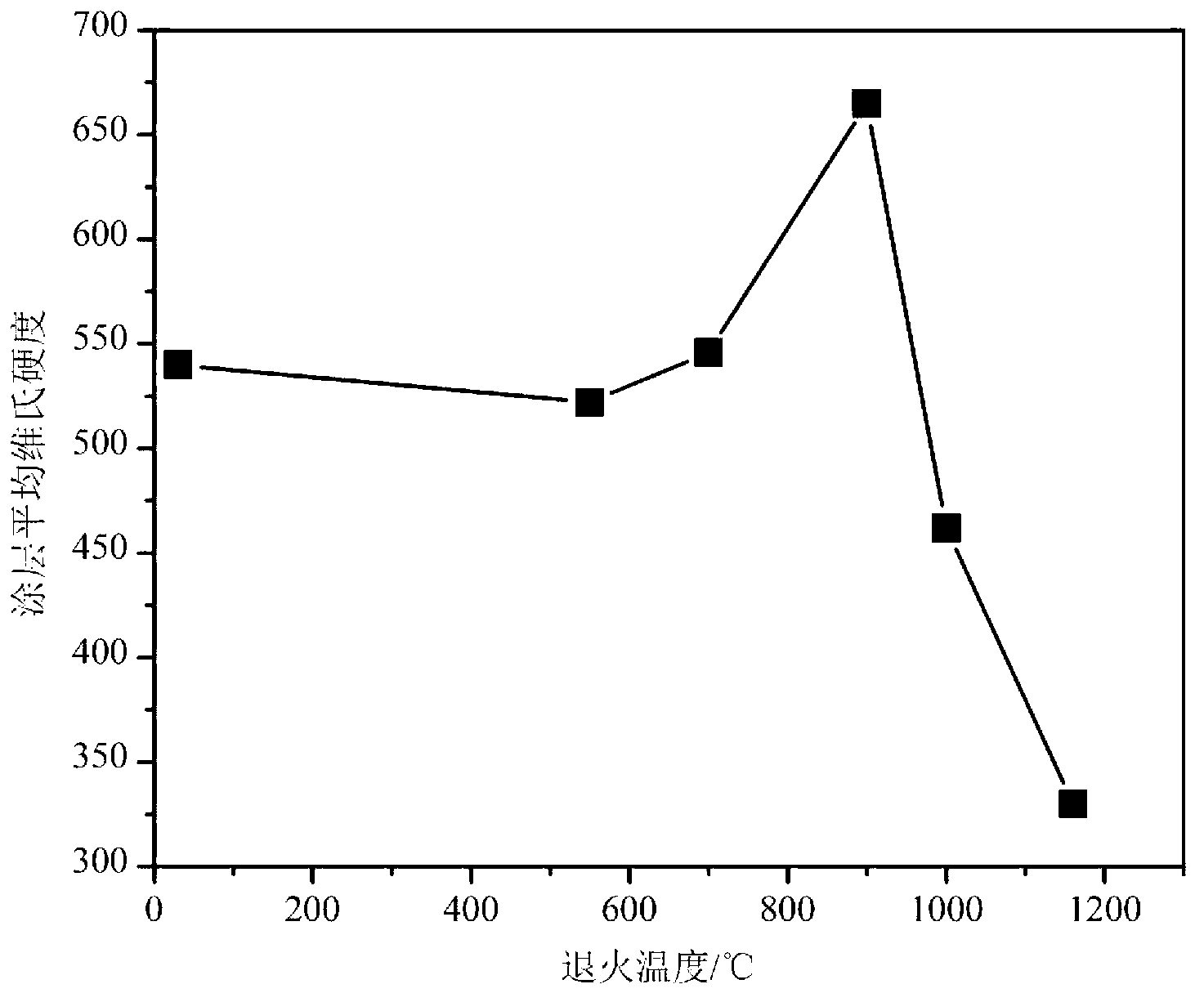

Examples

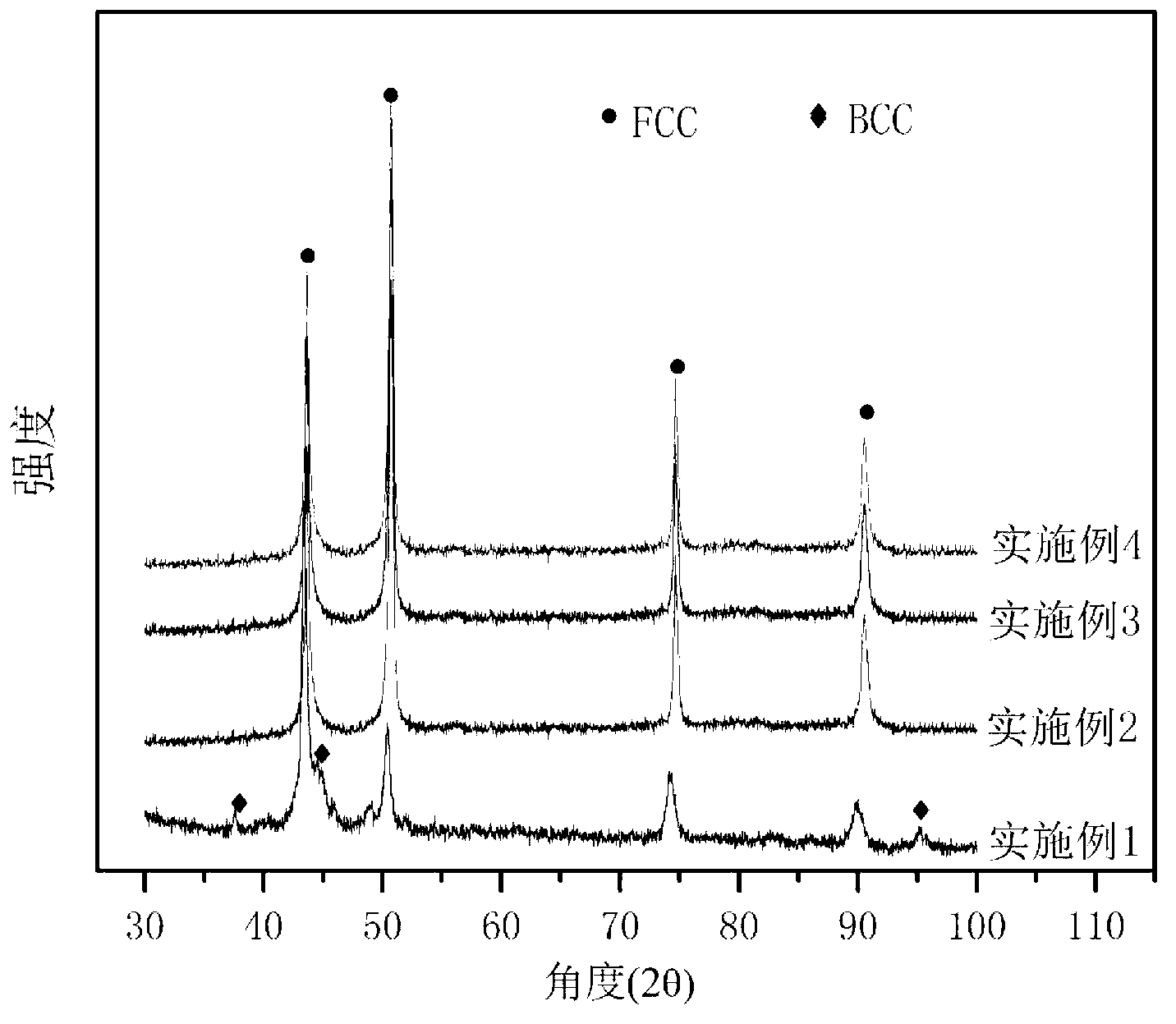

Embodiment 1

[0022] The powder design is carried out according to the nominal high-entropy alloy composition, regardless of the dilution of each element and the different burning loss, and the equimolar ratio of Mn, Cr, Ni, Fe, Co powder is configured. The mass percentage content of each element is as follows: 19.9% Fe, 18.5% Cr, 21% Ni, 21% Co, 19.6% Mn.

[0023] According to the above formula, select pure metal element powder to configure high-entropy alloy powder. The configured powder is milled in a ball mill for 3-10 hours. The speed of the ball mill is 250-500 rpm. The ball mill tank is filled with inert gas Ar for protection. The role of ball milling is to mix the powder evenly on the one hand, and to pre-alloy the powder on the other hand. After the ball milling, the powder is preset on the 45 steel base, the preset thickness is 1.2mm, the adhesive is rosin alcohol solution, and the preset coating is dried in CO 2 The high-power laser is used for multi-pass cladding, the laser p...

Embodiment 2

[0025] Considering the dilution of each element and different burning loss situations, according to the design of a high-entropy alloy powder for laser cladding carried out in claim 1, its composition mass percentage content is: 14.2% Fe, 16.5% Cr, 24.3% Ni, 22.4% Co, 22.6% Mn.

[0026] According to the above formula, select pure metal element powder to configure high-entropy alloy powder. The configured powder is milled in a ball mill for 3-10 hours. The speed of the ball mill is 250-500 rpm. The ball mill tank is filled with inert gas Ar for protection. After the ball milling, the powder is preset on the 45 steel base, the preset thickness is 1.2mm, the adhesive is rosin alcohol solution, and the preset coating is dried in CO 2 The high-power laser is used for multi-pass cladding, the laser power used is 1.5-1.7kW, the scanning speed is 100-450mm / min, the spot diameter is 4mm, and the inert gas Ar gas is used for protection during cladding.

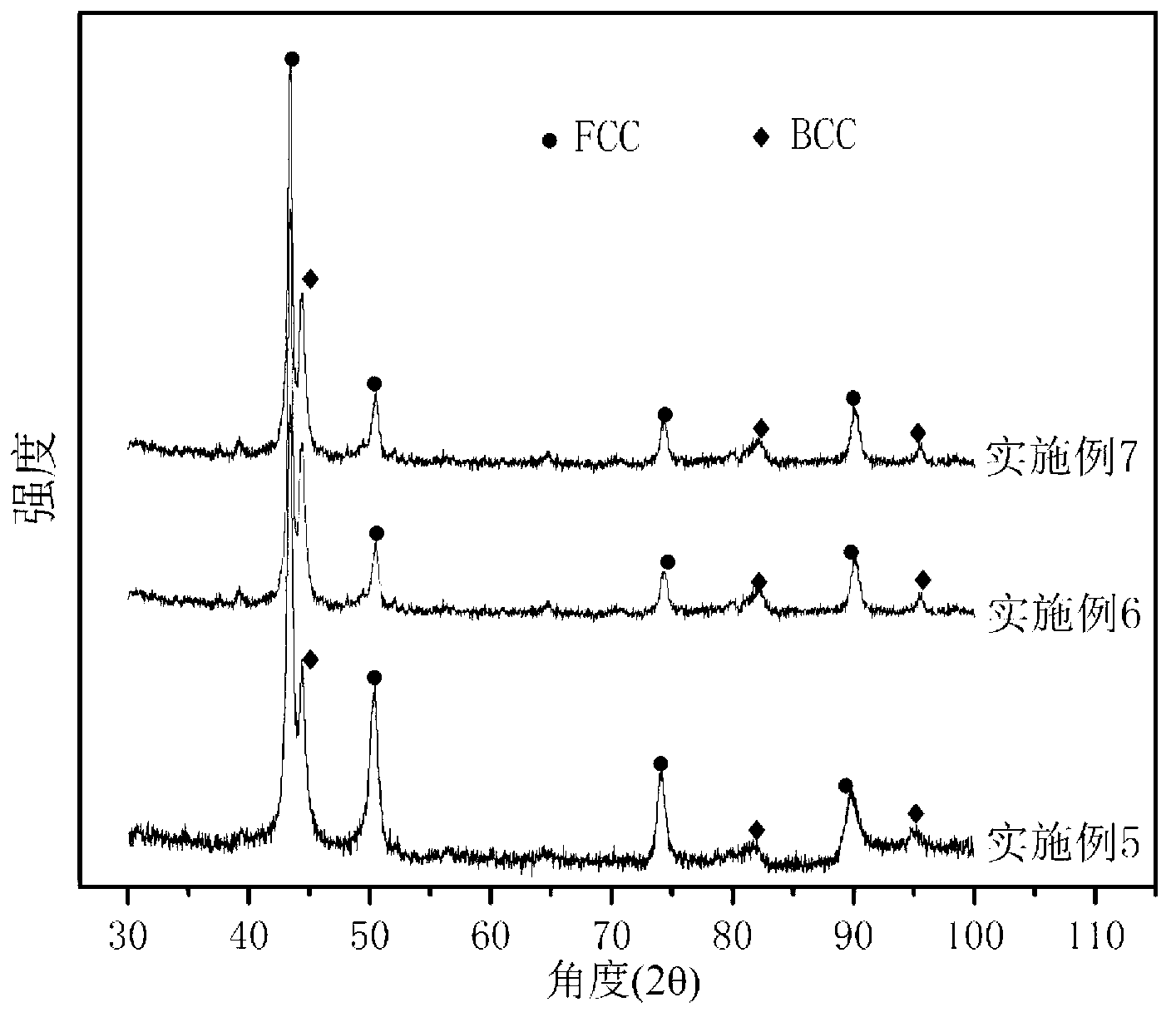

Embodiment 3

[0028]Considering the dilution of each element and different burning loss situations, according to the design of a high-entropy alloy powder for laser cladding carried out in claim 1, the composition mass percentage content is: 10.6% Fe, 13.4% Cr, 23.3% Ni, 23.3% Co, 23.4% Mn, 3% Si, 3% B.

[0029] According to the above formula, select pure metal element powder to configure high-entropy alloy powder. The configured powder is milled in a ball mill for 3-10 hours. The speed of the ball mill is 250-500 rpm. The ball mill tank is filled with inert gas Ar for protection. After the ball milling, the powder is preset on the 45 steel base, the preset thickness is 1.2mm, the adhesive is rosin alcohol solution, and the preset coating is dried in CO 2 The high-power laser is used for multi-pass cladding, the laser power used is 1.5-1.7kW, the scanning speed is 100-450mm / min, the spot diameter is 4mm, and the inert gas Ar gas is used for protection during cladding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com