High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

A high-entropy alloy and 3D printing technology is applied in the field of high-entropy alloy powder and preparation of high-entropy alloy coating to achieve the effects of fine grains, improved operability, and low element burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: The high-entropy alloy powder used for 3D printing in this embodiment consists of Ni: 16%-25%, Co: 16%-25%, Cr: 16%-25%, Ti: 16 %~25% and V: 16%~25% composition.

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the high-entropy alloy powder used for 3D printing consists of Ni: 18%-22%, Co: 18%-22%, and Cr: 18% by atomic percentage. %~22%, Ti: 18%~22% and V: 18%~22%.

specific Embodiment approach 3

[0016] Specific embodiment three: In this embodiment, the method for preparing a high-entropy alloy coating using high-entropy alloy powder is realized in the following steps:

[0017] 1. Ni is weighed according to the atomic percentage of 16% to 25% of Ni, 16% to 25% of Co, 16% to 25% of Cr, 16% to 25% of Ti and 16% to 25% of V Powder, Co powder, Cr powder, Ti powder and V powder are used as raw materials, and then the raw materials are placed in a ball mill for ball milling to obtain a mixed powder;

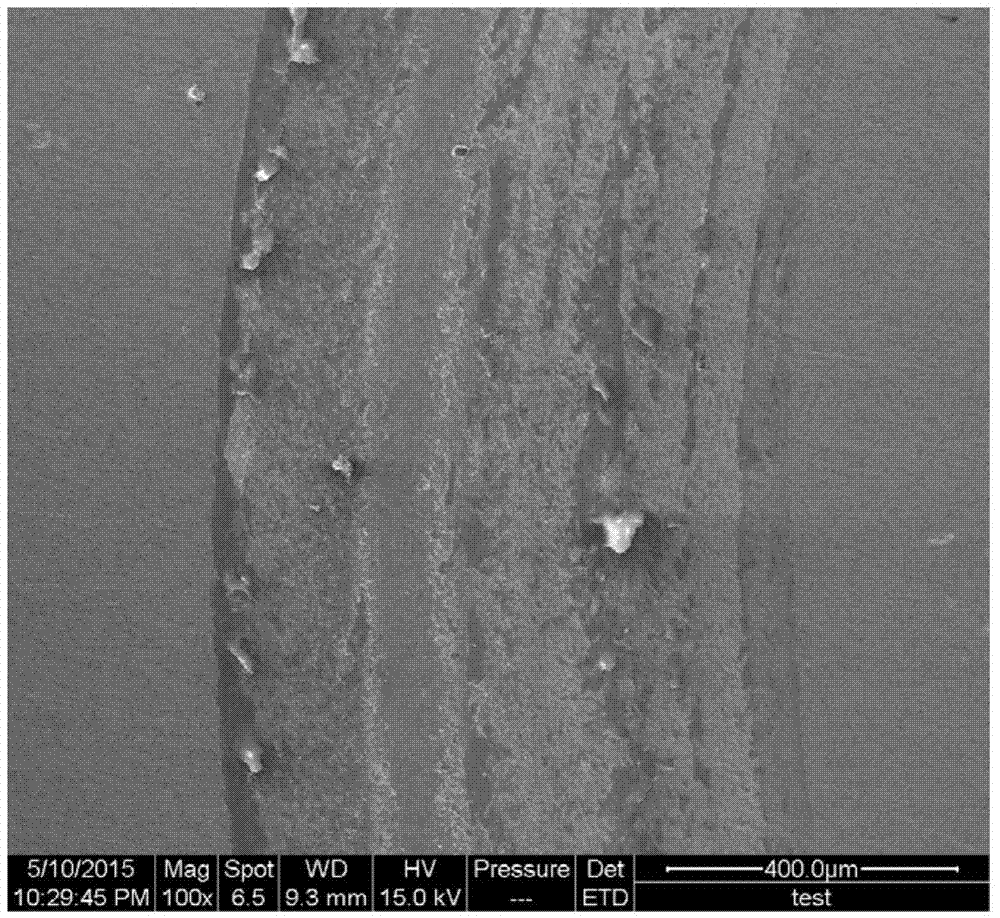

[0018] 2. Use sandpaper to smooth the surface of the substrate, then use absolute ethanol and acetone to clean the polished substrate in turn, and sandblast roughening to obtain a roughened substrate;

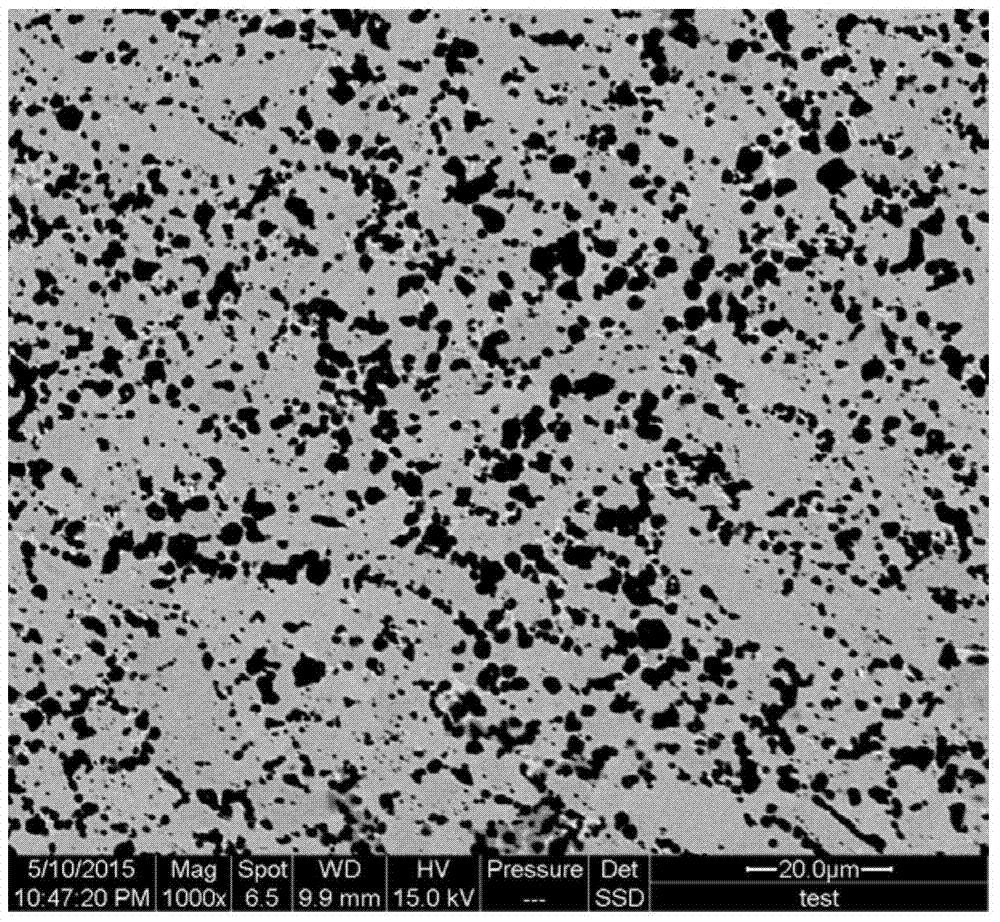

[0019] 3. Put the mixed powder obtained in step 1 into the powder feeder of the 3D printing equipment, adopt the laser selective sintering method, control the laser output power P = 500 ~ 700W, and the spot diameter D = 4 ~ 6mm, after roughening A high-entropy alloy coating is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com