Method for extracting chlorogenic acid from honeysuckle by using compound enzyme method

A compound enzyme method and chlorogenic acid technology, applied in the separation/purification of carboxylic acid esters, organic chemistry, etc., can solve the problems of cumbersome operation, popular use, large investment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Accurately weigh 5 g of honeysuckle medicinal material powder through a No. 4 sieve, and then dissolve the compound enzyme in an aqueous solution of 10 times the amount of medicinal material powder for subsequent use;

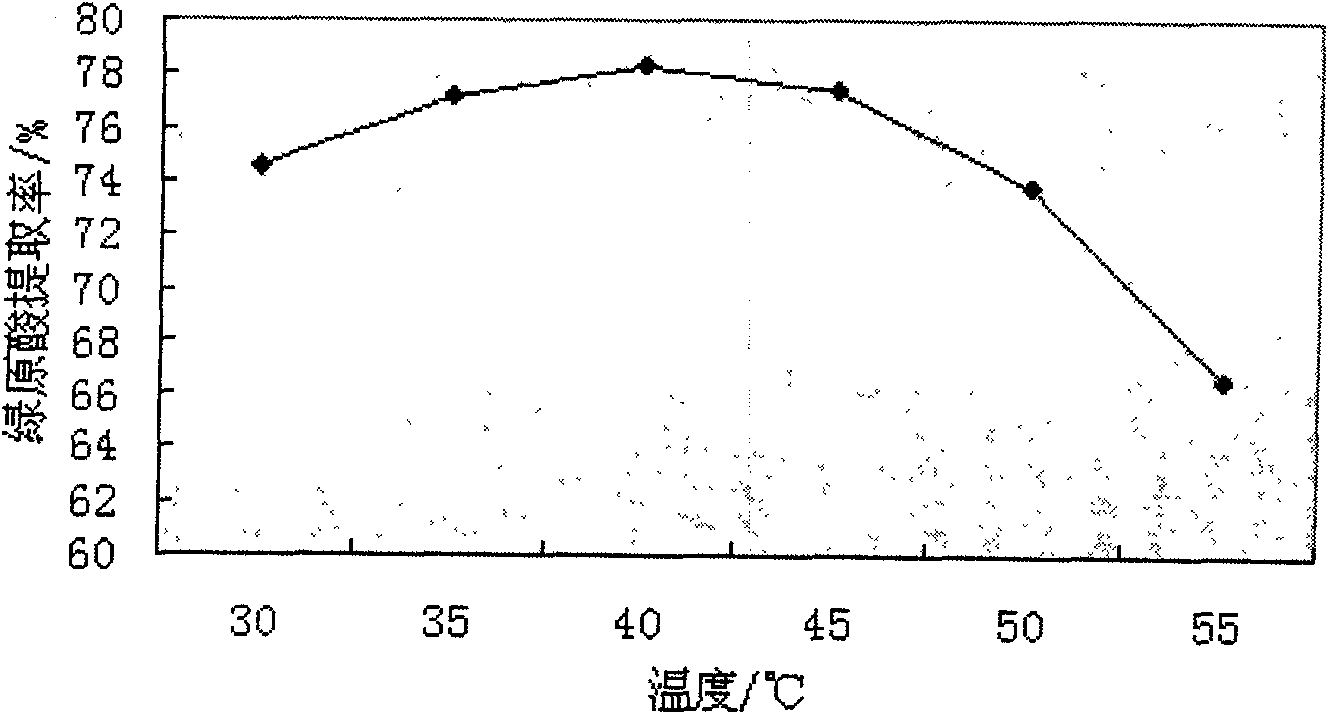

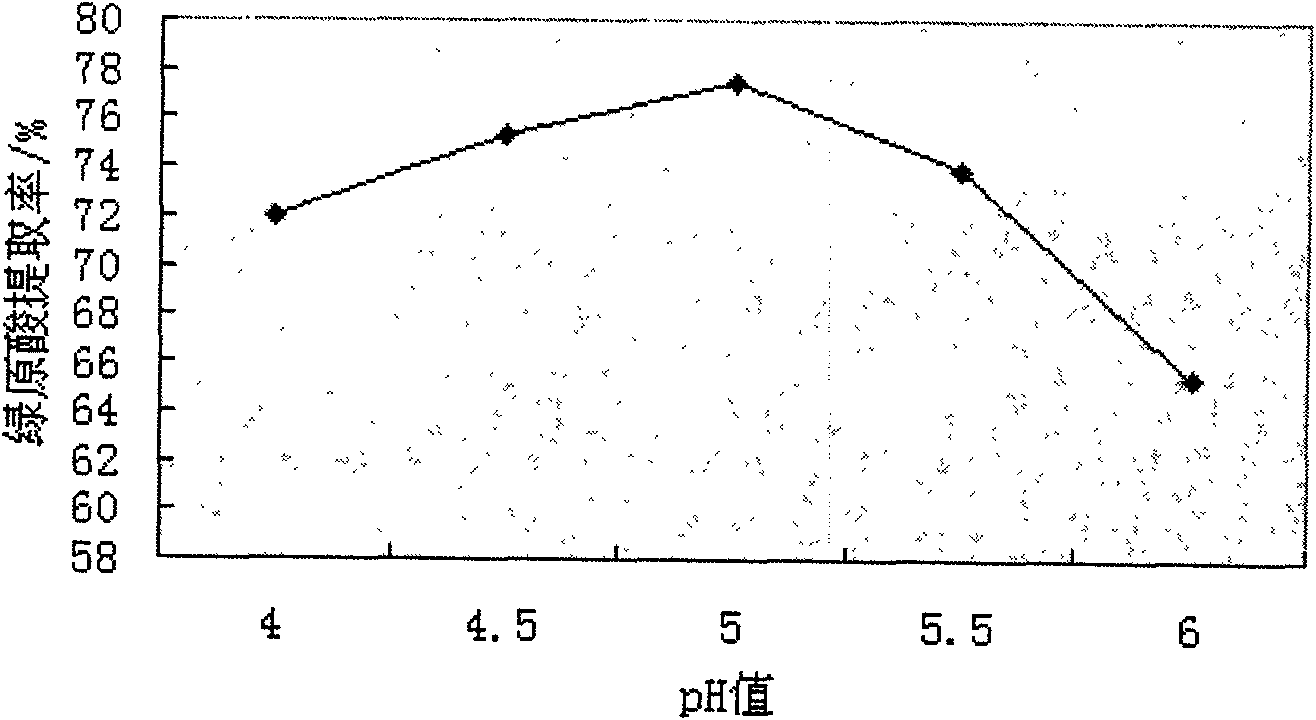

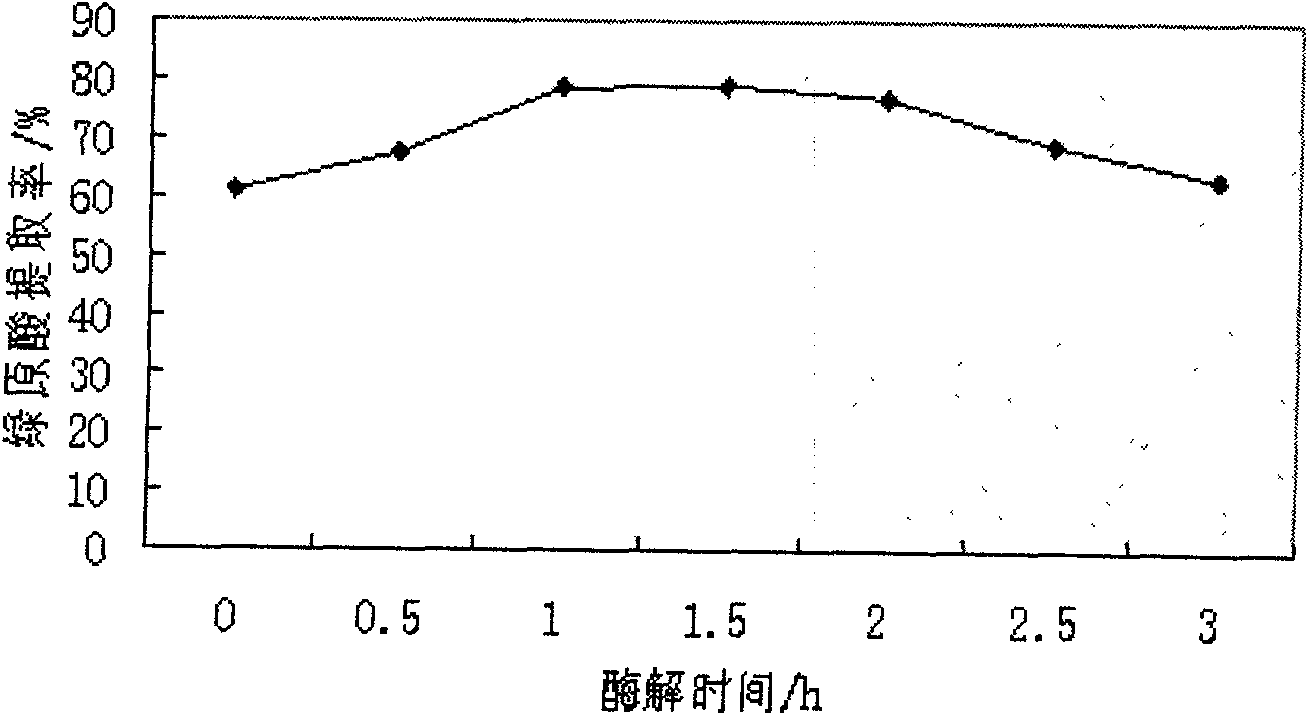

[0076] (2) Add compound enzyme according to 200U / g medicinal material (U is activity unit), control enzymolysis temperature at 40°C, pH value 4.5, enzymolysis time 1.5 hours, and process honeysuckle; wherein the compound ratio of cellulase and pectinase is 1.0:0.3.

[0077] (3) After the enzymatic hydrolysis is completed, add water at 70°C in an amount 10 times the weight of the medicinal material, extract twice, each time for 2 hours, combine the leachate, and concentrate under reduced pressure;

[0078] (4) Dissolve the concentrated solution in 50% methanol solution, set the volume to 50mL, accurately draw 1mL and use 50% methanol solution to set the volume to 100mL, measure the content of chlorogenic acid by HPLC method to be 2.34%, and calculate ...

Embodiment 2

[0080] (1) Accurately weigh 5 g of honeysuckle medicinal material powder through a No. 4 sieve, and then dissolve the compound enzyme in an aqueous solution of 10 times the amount of medicinal material powder for subsequent use;

[0081] (2) Add compound enzyme according to 400U / g medicinal material (U is activity unit), control enzymolysis temperature at 45°C, pH value 5, enzymolysis time 2 hours, process honeysuckle; wherein the compound ratio of cellulase and pectinase is 1.0:0.28.

[0082] (3) After the enzymatic hydrolysis is completed, add water at 75°C in an amount 10 times the weight of the medicinal material, extract 3 times, each time for 3 hours, combine the leachate, and concentrate under reduced pressure;

[0083] (4) Dissolve the concentrated solution in 50% methanol solution, set the volume to 50mL, accurately draw 1mL and use 50% methanol solution to set the volume to 100mL, measure the content of chlorogenic acid by HPLC method to be 2.34%, and calculate the e...

Embodiment 3

[0085] (1) Accurately weigh 5 g of honeysuckle medicinal material powder through a No. 4 sieve, and then dissolve the compound enzyme in an aqueous solution of 10 times the amount of medicinal material powder for subsequent use;

[0086] (2) Add compound enzyme according to 400U / g medicinal material (U is activity unit), control enzymolysis temperature at 40°C, pH value 4.5, enzymolysis time 2 hours, process honeysuckle; wherein the compound ratio of cellulase and pectinase is 1.0:3.

[0087] (3) After the enzymatic hydrolysis is completed, add water at 70°C in an amount 10 times the weight of the medicinal materials, extract twice, each time for 3 hours, combine the extracts, and concentrate under reduced pressure;

[0088] (4) Dissolve the concentrated solution in 50% methanol solution, set the volume to 50mL, accurately draw 1mL and use 50% methanol solution to set the volume to 100mL, measure the content of chlorogenic acid by HPLC method to be 2.34%, and calculate the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com