Si-Si bonding isolator upper silicon high-temperature pressure sensor chip and manufacture method

A technology of a pressure sensor and a manufacturing method, which is applied in the fields of semiconductor/solid-state device parts, piezoelectric/electrostrictive/magnetostrictive devices, and the measurement of the property force of piezoresistive materials, etc., can solve the problem of process stability. High, it is difficult to ensure the uniformity of the stress film, etc., to achieve the effect of ensuring long-term stability, suitable for mass production, and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

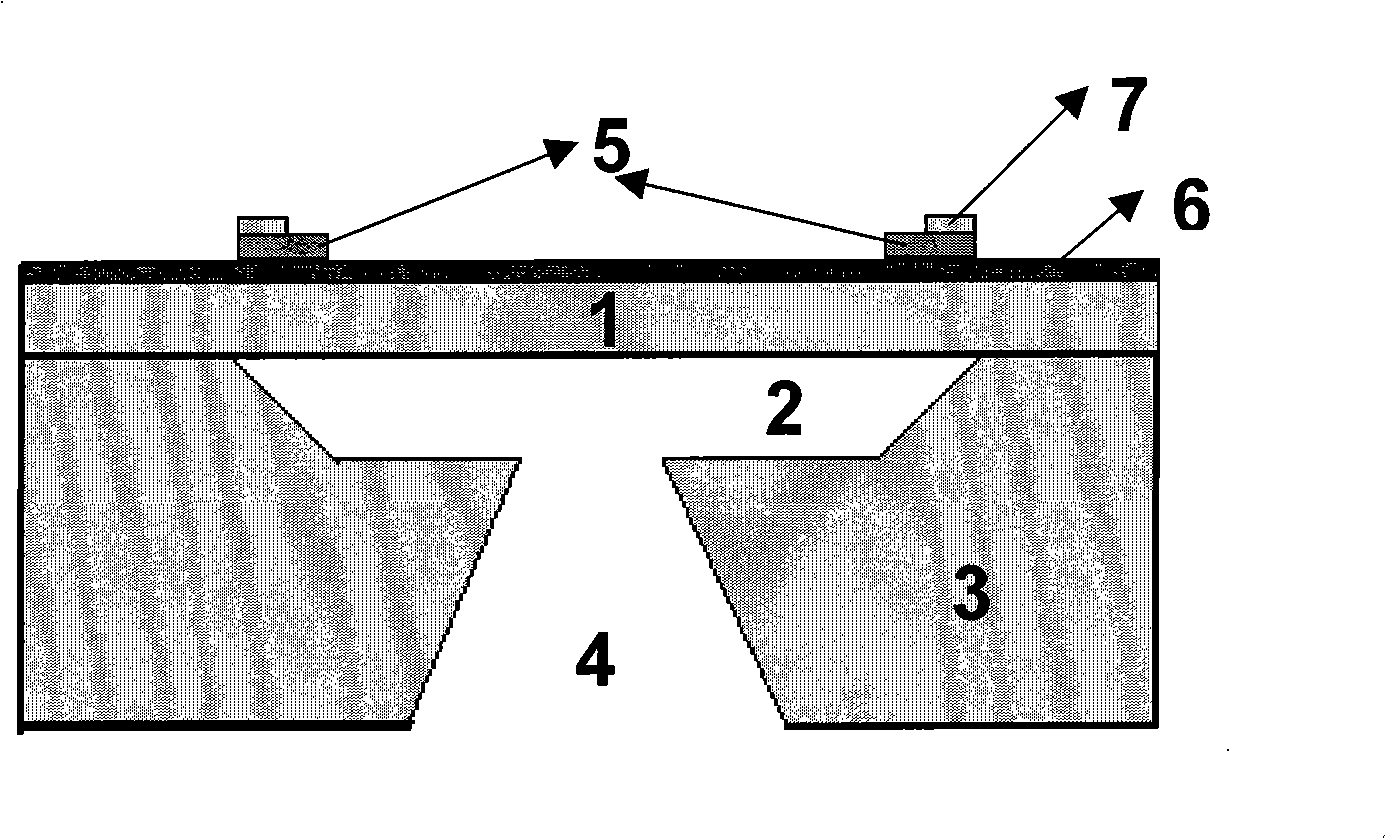

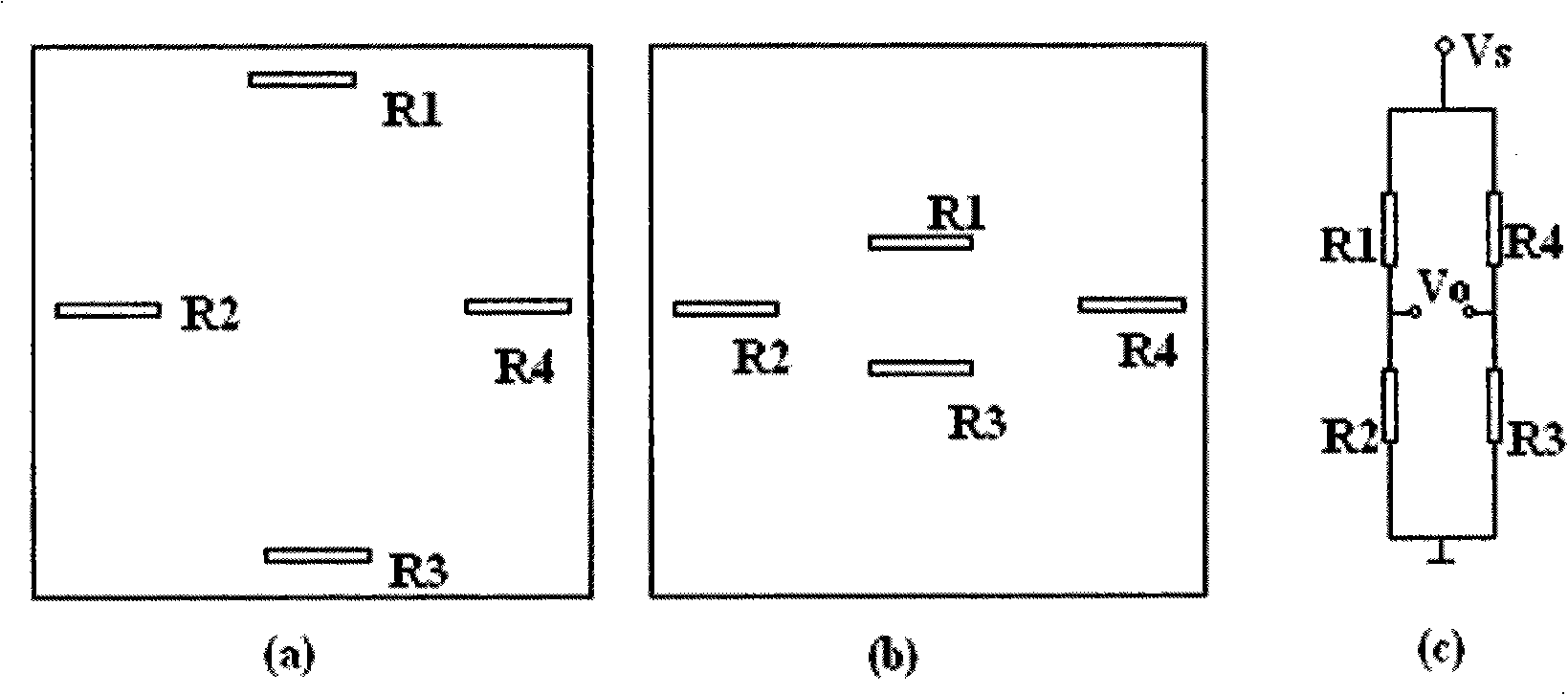

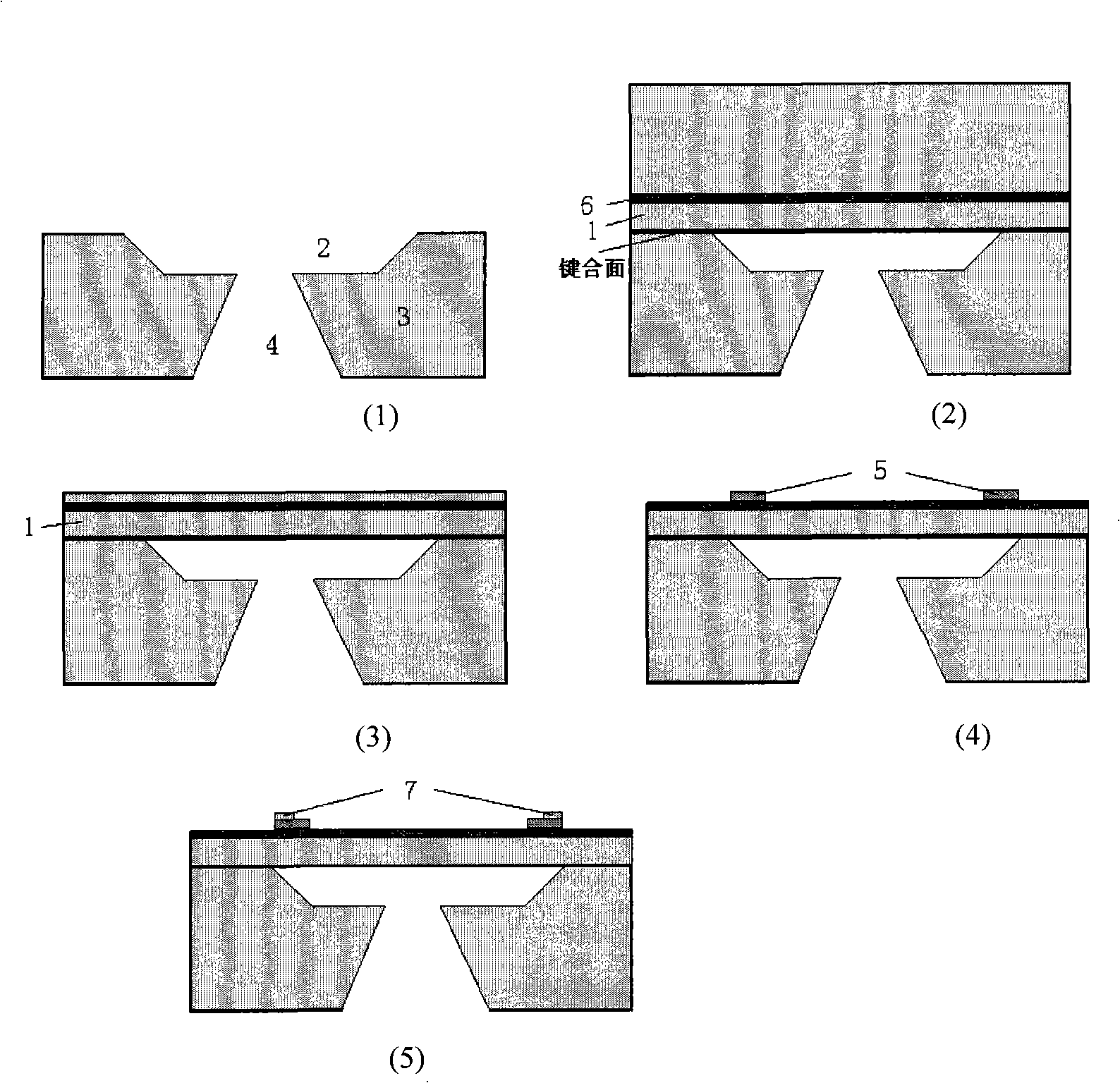

[0018] The following examples will help to understand the present invention, but do not limit the content of the present invention. The manufacturing method of silicon-on-insulator high-temperature pressure sensor chip suitable for silicon-silicon bonding in the range of 1MPa:

[0019] Using 4-inch 450μm N-type (100) double-polished single-crystal silicon wafers, the resistivity is 1-10ohm.cm, and 4-inch P-type double-polished SOI wafers, the thickness of the top silicon layer and the buried layer are 60 microns and 1 micron respectively , the top silicon resistivity 1-10ohm.cm.

[0020] 1. Clean the silicon wafer and then oxidize it. Use front and back photolithography to align, and use the oxide layer as a mask to etch shallow grooves and air guide holes in KOH solution, corresponding to image 3 (1);

[0021] 2. SOI wafers and silicon wafers are bonded on the shallow groove surface. Use 400°C vacuum in the bonding machine, pressurize 2bar for 20 minutes, and then dry oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com