Nitrogen fertilizer stabilizer composition and preparation method thereof

A technology of composition and stabilizer, which is applied in the field of nitrogen fertilizer stabilizer and its preparation, can solve the problems of reduced utilization of Nitrapyrin, loss of Nitrapyrin utilization, and different sensitivity of nitrogen oxidation inhibitors, so as to prolong the action time and improve nitrogen utilization rate , The effect of facilitating the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

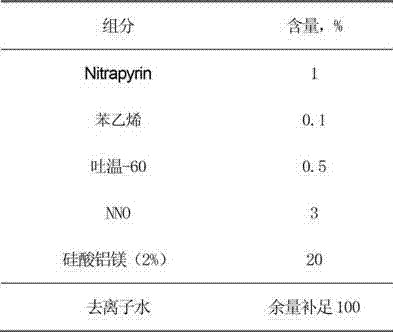

Embodiment 1

[0043]

[0044] 1g of Nitrapyrin was heated past the melting point and melted into a liquid state, then 0.1g of styrene was added and stirred evenly to become the active ingredient mother liquor; 0.5g of emulsifier Tween-60 and aqueous solution were added to 50g of deionized water and stirred evenly to form an aqueous solution; Put the prepared mother liquor into the aqueous solution and turn on the high-speed homogenization to form a stable O / W emulsion; turn on the stirring (maintain 300 rpm), and then raise the temperature of the homogenized emulsion to 30°C to maintain the solidification of the stable capsule wall material After 5 hours of temperature, add 3g of NNO naphthalene sulfonate and 20g of magnesium aluminum silicate (2%) aqueous solution, add water to 100g and stir evenly to prepare 1% Nitrapyrin microcapsule sustained release agent.

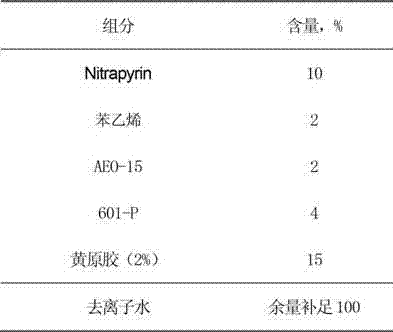

Embodiment 2

[0046]

[0047] Heat 10g of Nitrapyrin over the melting point and melt into a liquid state, then add 2g of styrene monomer and stir evenly to the active ingredient mother liquor; add 2.0g of emulsifier fatty alcohol polyoxyethylene ether AEO-15 (Xingtai Bluestar) into 50g of Stir in deionized water to form an aqueous solution; put the prepared mother liquor into the aqueous solution and turn on high-speed homogenization to form a stable O / W emulsion; turn on stirring (maintain 450 rpm), and then raise the temperature of the homogenized emulsion to 70°C, maintain a stable solidification temperature of the capsule wall material for 7 hours, then add 4.0g of dispersant phosphate esters 601P, 15g of xanthan gum (2%) aqueous solution, add water to 100g and stir evenly to prepare 10% Nitrapyrin microcapsules slow release agent.

Embodiment 3

[0049]

[0050]

[0051] Heat 24g of Nitrapyrin over the melting point and melt into a liquid state, then add 6g of styrene and 2g of acrylate to stir evenly the active ingredient mother liquor; add 2.0g of emulsifier fatty alcohol polyoxyethylene ether AEO-9 (Nanjing Taihua) Add 40g of deionized water and stir to form an aqueous solution; put the prepared mother liquor into the aqueous solution and turn on high-speed homogenization to form a stable O / W emulsion; turn on stirring (maintain 400 rpm), and then put the homogenized The temperature of the emulsion is raised to 50°C, and the solidification temperature of the capsule wall material is maintained for 5 hours, then 5.0g of sodium lignosulfonate and 10g of xanthan gum (2%) aqueous solution are added as a dispersant, and the water is replenished to 100g and stirred evenly to obtain 24% Nitrapyrin microcapsule sustained release formulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com