Patents

Literature

42 results about "Nitrapyrin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

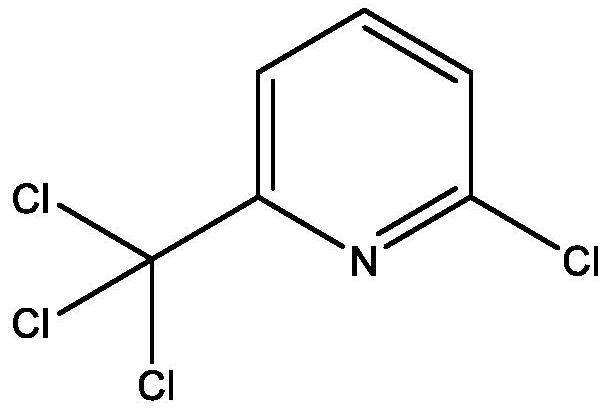

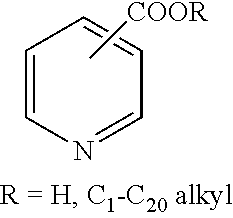

Nitrapyrin is an organic compound with the formula ClC₅H₃NCCl₃. It is a widely used nitrification inhibitor in agriculture as well as a soil bactericide and has been in use since 1974. Nitrapyrin was put up for review by the EPA and deemed safe for use in 2005. Since nitrapyrin is an effective nitrification inhibitor to the bacteria nitrosomonas it has been shown to drastically the reduce NO₂ emissions of soil. Nitrapyrin is a white crystalline solid with a sweet odor and is often mixed with anhydrous ammonia for application.

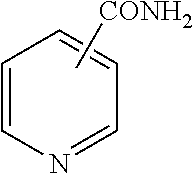

Nitrogen fertilizer stabilizer composition and preparation method thereof

InactiveCN103044137AImprove efficiencyImprove compatibilityFertilizer mixturesNitrapyrinNitrogen fertilizer

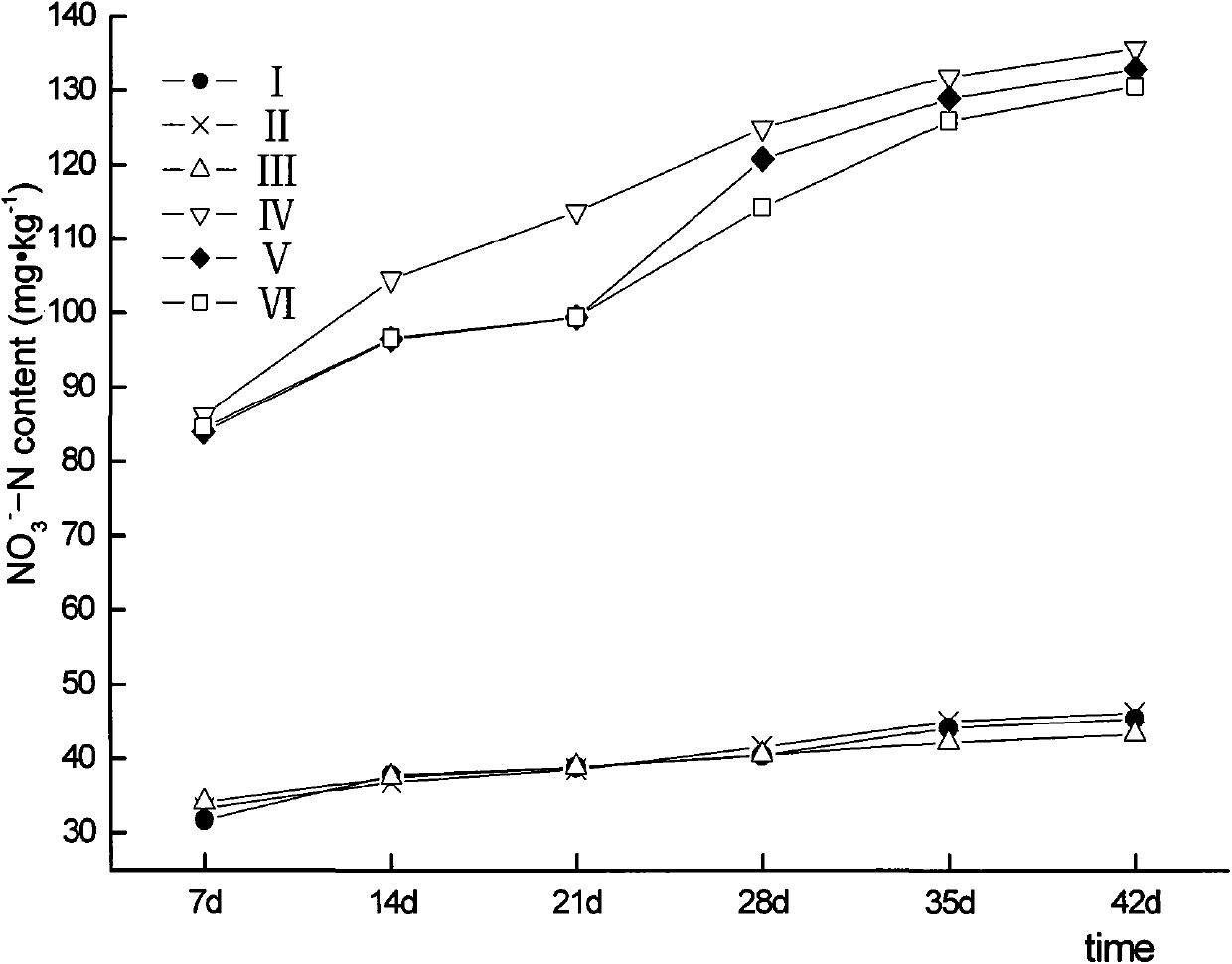

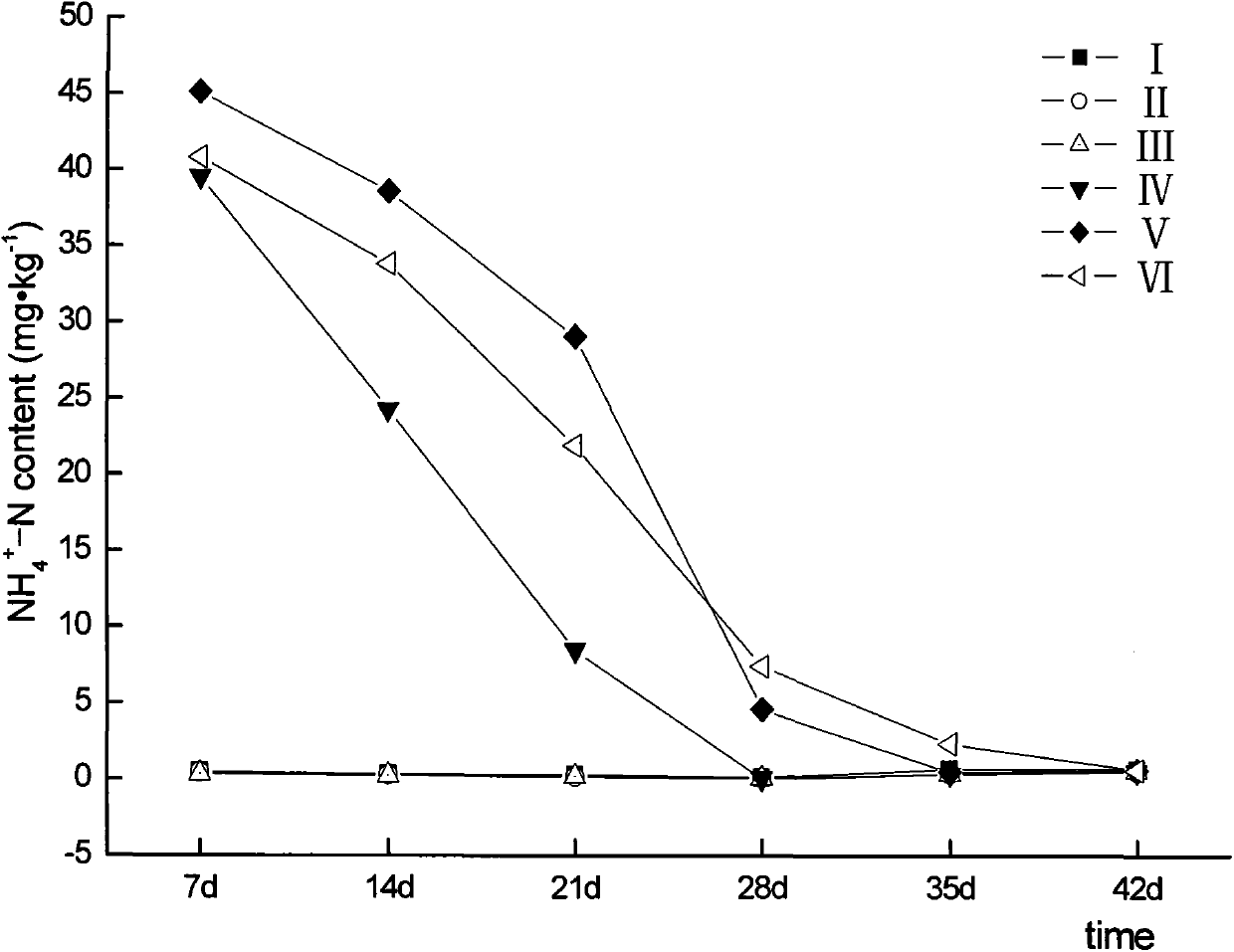

The invention discloses a nitrogen fertilizer stabilizer composition. The nitrogen fertilizer stabilizer composition comprises the following components in part by weight: 1-60 parts of nitrapyrin, 1-15 parts of wall material, 2-10 parts of emulsifier, 0.05-0.3 parts of viscosity regulator, 2-10 parts of dispersing agent and 0.1-100 parts of water. The invention further provides a preparation method of the nitrogen fertilizer stabilizer composition. The preparation method of the nitrogen fertilizer stabilizer composition comprises the following steps of: heating and melting active components, adding the macromolecular wall material, and stirring uniformly; adding a mother liquid containing the active components and the wall material into an emulsifier-containing water solution under a shearing condition, and emulsifying into an oil-in-water state; and controlling grain size as required, wherein the nitrogen fertilizer stabilizer composition can be in a liquid or solid state; and liquid drops containing the active components react with water molecules to form the macromolecular wall material. Through addition of a nitrapyrin product, the nitrogen fertilizer stabilizer composition can improve the using efficiency of an ordinary nitrogen fertilizer by decreasing nitrogen leaching and denitrification, is good in compatibility with a variety of fertilizers, pesticides, weedicides and bactericides, and can be mixed therewith for application.

Owner:南通联农佳田作物科技有限公司

Preparation method for silica gel-loaded aminomethylpyridine chelating resin for deep copper removal

InactiveCN102441367AHigh adsorption capacityIncrease loadOther chemical processesSilica gelChelating resin

The present invention relates to a preparation method for a silica gel-loaded aminomethylpyridine chelating resin for deep copper removal. According to the method, a silicane coupling agent reacts with 2-aminomethylpyridine under an anhydrous condition to generate an aminomethylpyridine modified silicane coupling agent; the aminomethylpyridine modified silicane coupling agent is grafted onto the surface of the activated silica gel. With the method of the present invention, the loading and the metal ion adsorption capacity of the functional groups of the chelating resin are effectively improved; the synthetic route is simple and economical. In addition, in the existing synthetic route, when silicon dioxide with the surface modification of the amino groups reacts with nitrapyrin to prepare the chelating resin, the alkality of the reaction system is high (the pH value is more than 11), and the silicon dioxide is dissolved, or the alkality of the reaction system is low (the pH value is less than 10), the nucleophilic substitution reaction efficiency between the nitrapyrin functional group and the amino group is low, and the loading of the functional group is not high. With the method of the present invention, the problems in the existing synthetic route are avoided.

Owner:CENT SOUTH UNIV

Non-corrosive nitrification inhibitor polar solvent formulation

ActiveUS20160332931A1Enhances crop performanceIncrease crop yieldNitrogenous fertilisersAgriculture gas emission reductionNitrification inhibitorsSolvent

This invention relates to stable liquid formulations of the nitrification inhibitor nitrapyrin comprising polar solvents that are stabilized with small amounts of compounds which help to reduce the tendency of polar solutions of nitrapyrin to corrode metal surfaces. Many of the formulations disclosed herein exhibit useful physical, chemical, and bioactive properties including reduced levels of corrosion when in contact with ferrous metals.

Owner:DOW AGROSCIENCES LLC +1

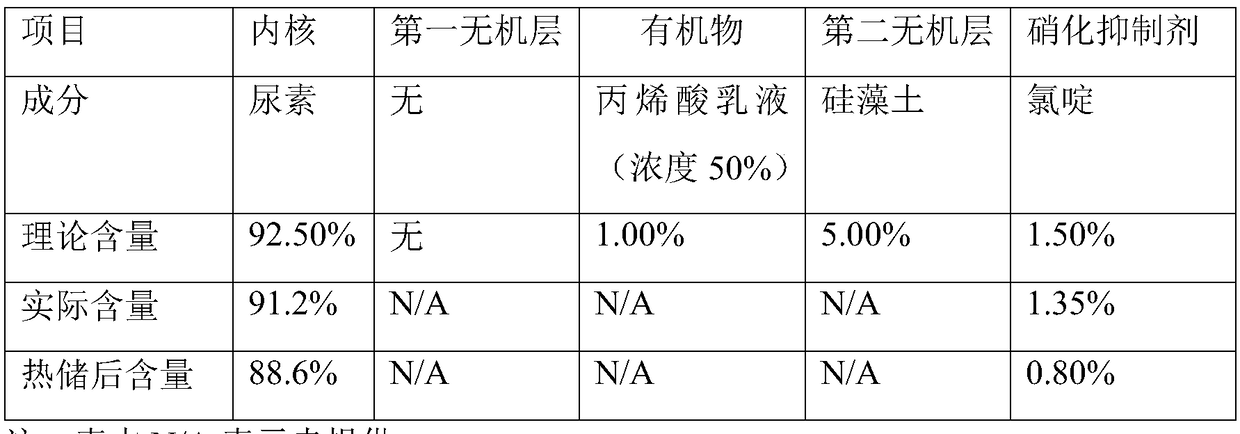

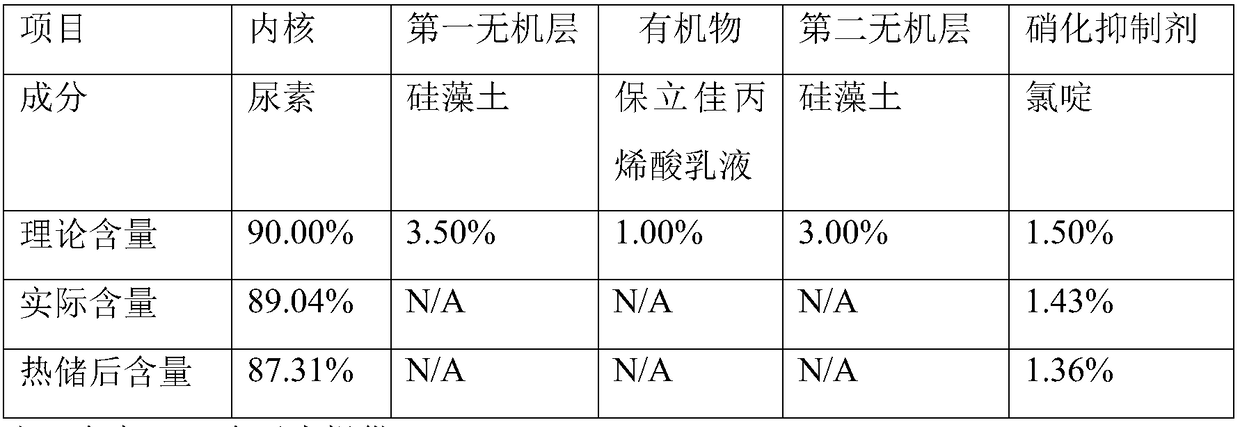

Stability urea and preparation method thereof

The invention provides stability urea and a preparation method thereof, and relates to urea and the preparation method thereof. The invention aims at solving the problems that the utilization rate of common urea is low, the fertilizer efficiency period of the common urea is short, N-(n-butyl) thiophosphoric-triamide and 2-chlorin-6-nitrapyrin cannot be used at a high temperature, and when an organic solvent is used for dissolving the N-(n-butyl) thiophosphoric-triamide and the 2-chlorin-6-nitrapyrin so as to prepare the stability urea, the urea becomes adhesive after absorbing moisture and is high in price and complicated in a production technology, and the organic solvent is risky for people and soil. The stability urea is prepared from the N-(n-butyl) thiophosphoric-triamide, the 2-chlorin-6-nitrapyrin, humic acid and urea. The preparation method comprises the following steps: 1, carrying out preheating treatment so as to obtain preheated urea; 2, firstly mixing the N-(n-butyl) thiophosphoric-triamide, the 2-chlorin-6-nitrapyrin and the humic acid, and then carrying out grinding treatment so as to obtain a mixture; and 3, adding the mixture to the preheated urea, carrying out heat preservation, stirring, sieving, and cooling to room temperature, thus obtaining the stability urea. The preparation method is mainly used for preparing the stability urea.

Owner:武威金仓生物科技有限公司

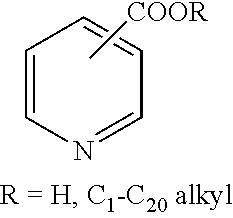

High-tower long-acting compound fertilizer and preparation method thereof

ActiveCN103524272AIncrease profitIncrease growth rateFertilizer mixturesNitrate nitrogenEthyl Chloride

The invention discloses high-tower long-acting compound fertilizer and a preparation method of the high-tower long-acting compound fertilizer. The high-tower long-acting compound fertilizer comprises 0.2-0.4% of 2-chlorine-6-nitrapyrin by weight, and the 2-chlorine-6-nitrapyrin can restrain ammonium nitrogen from being converted into nitrate nitrogen and prolong fertilizer efficiency for more than one month. The high-tower long-acting compound fertilizer is prepared through a high-tower fusing pelleting technology, a formula amount of the 2-chlorine-6-nitrapyrin is added after the fertilizer is pelletized, film packaging is carried out at the temperature of 80-90 DEG C, the prepared fertilizer is smooth and through in particle, small holes are formed in the surfaces of the fertilizer particles, and the high-tower long-acting compound fertilizer is uniform in nutrient, high in strength, easy to dissolve, and not prone to caking.

Owner:重庆九禾测土配肥有限责任公司

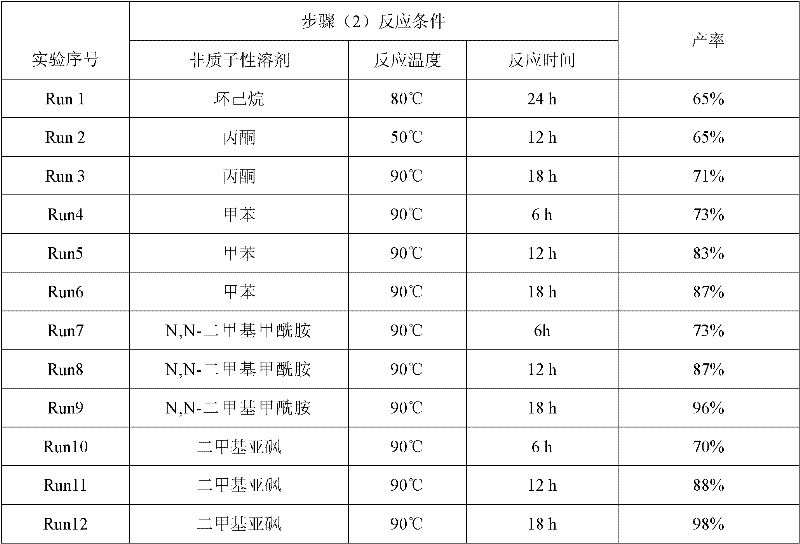

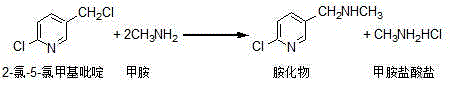

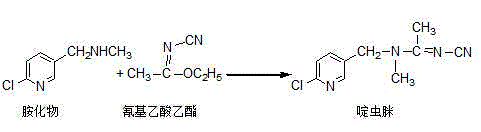

Production process of acetamiprid

InactiveCN104803910AAmination reaction temperature is lowThree wastes lessOrganic chemistryDistillationReaction temperature

The invention discloses a production process of acetamiprid. The production process comprises steps as follows: a, amination: chloroform is added to an amination reaction kettle at the room temperature and methylamine gas is introduced into a chloroform solution and below the liquid level, 2-chloro-5-nitrapyrin is dropwise added to the reaction kettle under the normal pressure at the room temperature, the reaction temperature is not higher than 20 DEG C, the materials are cooled to the room temperature, added with water, stirred for 1-2 h and left to stand for layering, chloroform is recovered through distillation under the normal pressure, and the materials after desolvation are cooled to the room temperature, added with ethanol for dissolving and then transferred to a next step for reaction; b, condensation: an ethanol solution of amide and ethyl n-cyanoethanimideate are proportionally put into a condensation kettle to be stirred, chilled brine is introduced, the mixture is cooled to 0 DEG C for crystallization, white solids are precipitated and then are filtered and dried, and a filtrate is sent to an ethanol distillation kettle for distillation at the temperature of 78-80 DEG C under the normal pressure, so that ethanol is recovered. The temperature of the amination reaction is lower, few by-products and little waste water are produced, the condensation reaction is simple, the reaction time is short, energy is saved, besides, the condensation reaction is an anhydrous reaction, and no waste water is produced.

Owner:JIANGSU CHANGQING AGROCHEM NANTONG

Method for manufacturing 2-chlorine-6-nitrapyrin microcapsule suspending agents

The invention discloses a method for manufacturing 2-chlorine-6-nitrapyrin microcapsule suspending agents. The method includes dissolving a certain quantity of 2-chlorine-6-nitrapyrin in a certain quantity of toluene to obtain solution, adding a small quantity of NP (nonyl phenol)-10 emulsifying agents into the solution, uniformly stirring the solution and then adding a certain quantity of urea resin solution into the solution to obtain mixed solution; shearing the mixed solution at a high rotational speed for 40 minutes, reducing the rotational speed after materials in the mixed solution are sufficiently dispersed, and slowly adding hydrochloric acid with the concentration of 37% into the mixed solution so that a pH (potential of hydrogen) value of the mixed solution is regulated and ranges from 2.5 to 3; enabling the mixed solution to perform acidification reaction for 1 hour to form microcapsule particles; reducing the rotational speed to 200r / min within 20 minutes, controlling the temperature to range from 40 DEG C to 50 DEG C, and solidifying the microcapsule particles for 1 hour; and regulating the pH value of the microcapsule particles by 7.5-15% of sodium hydroxide aqueous solution so that the pH value ranges from 5 to 7, and adding 10-25% of NP-10 emulsifying agents into the microcapsule particles to form the microcapsule suspending agents. The method has the advantages that the products manufactured by the method are good in stability and low in environmental pollution, and contain few organic solvents, the cost is saved, and injury to operators is prevented.

Owner:JIANGSU SANDI CHEM CO LTD

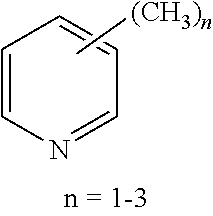

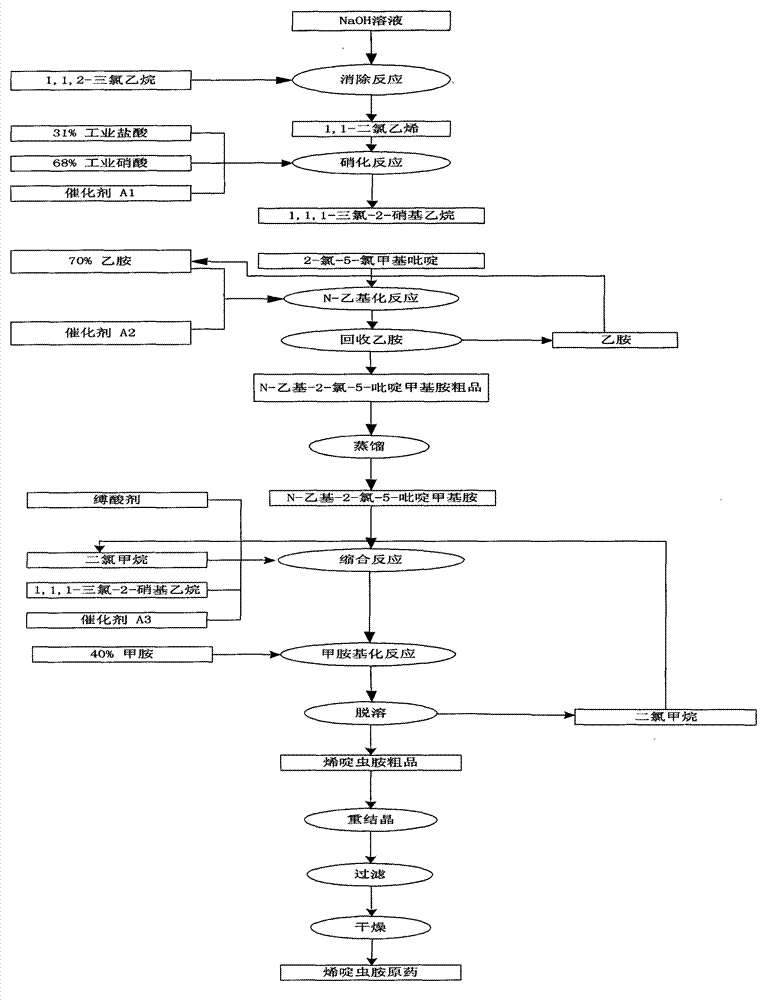

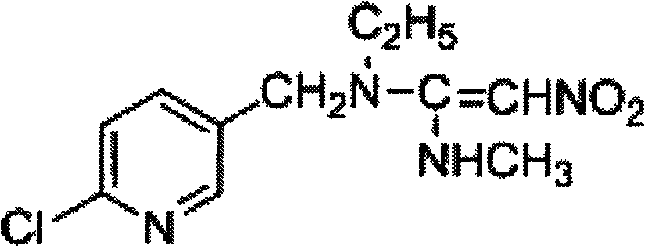

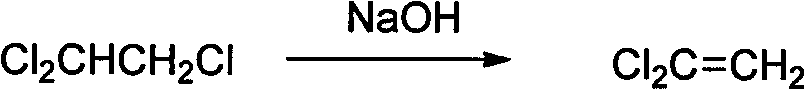

Method for preparing pesticide nitenpyram

The invention relates to a method for synthesizing a pesticide, and in particular relates to a method for preparing a pesticide nitenpyram. The method for preparing the pesticide nitenpyram is characterized in that 1, 1, 1, 2-trichloroethane is taken as a starting material, and an intermediate of 1, 1, 1-trichloro-2-nitroethane is directly synthesized through elimination reaction and catalytical nitration reaction; 2, 2-chloro-5-nitrapyrin is taken as a staring material, water is taken as solvent, a phase-transfer catalysis technology is adopted, and an intermediate of N-ethyl-2-chloro-5-pyridyl methyl amine is obtained through N-alkylation reaction; and 3, the two intermediates are mixed together, dichloromethane with low toxicity is taken as the solvent, condensation and methyl amination reaction are carried out in a same reaction vessel, and the nitenpyram is produced through extracting, desolventizing and crystallizing. The method for preparing the pesticide nitenpyram has high product yield and purity and a short technological process. Compared with the prior art, the method has the advantages of high total yield, low cost, high product purity, less environmental pollution, benefits for industrial production and the like.

Owner:浙江禾本科技股份有限公司

Nitrification inhibitor compositions and methods of making thereof

ActiveUS20170253535A1Agriculture gas emission reductionSolid/semi-solid fertilisersNitrification inhibitorsNitrapyrin

An improved nitrification inhibitor composition comprising UFP particles and a nitrification inhibitor, and optionally other components, is used as an additive for liquid and solid fertilizers, typically containing urea. The nitrification inhibitor particularly can be nitrapyrin and / or DMPP. Methods of making the compositions and their use are also disclosed.

Owner:KOCH AGRONOMIC SERVICES LLC

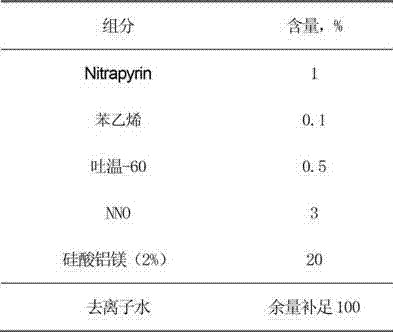

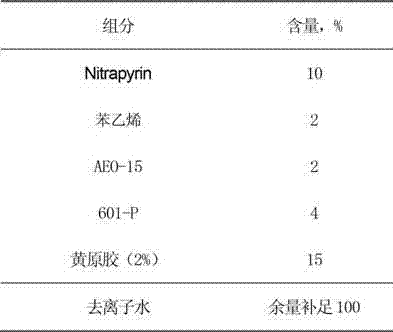

Colloidal suspension agent for nitrogen fertilizer synergism and application thereof

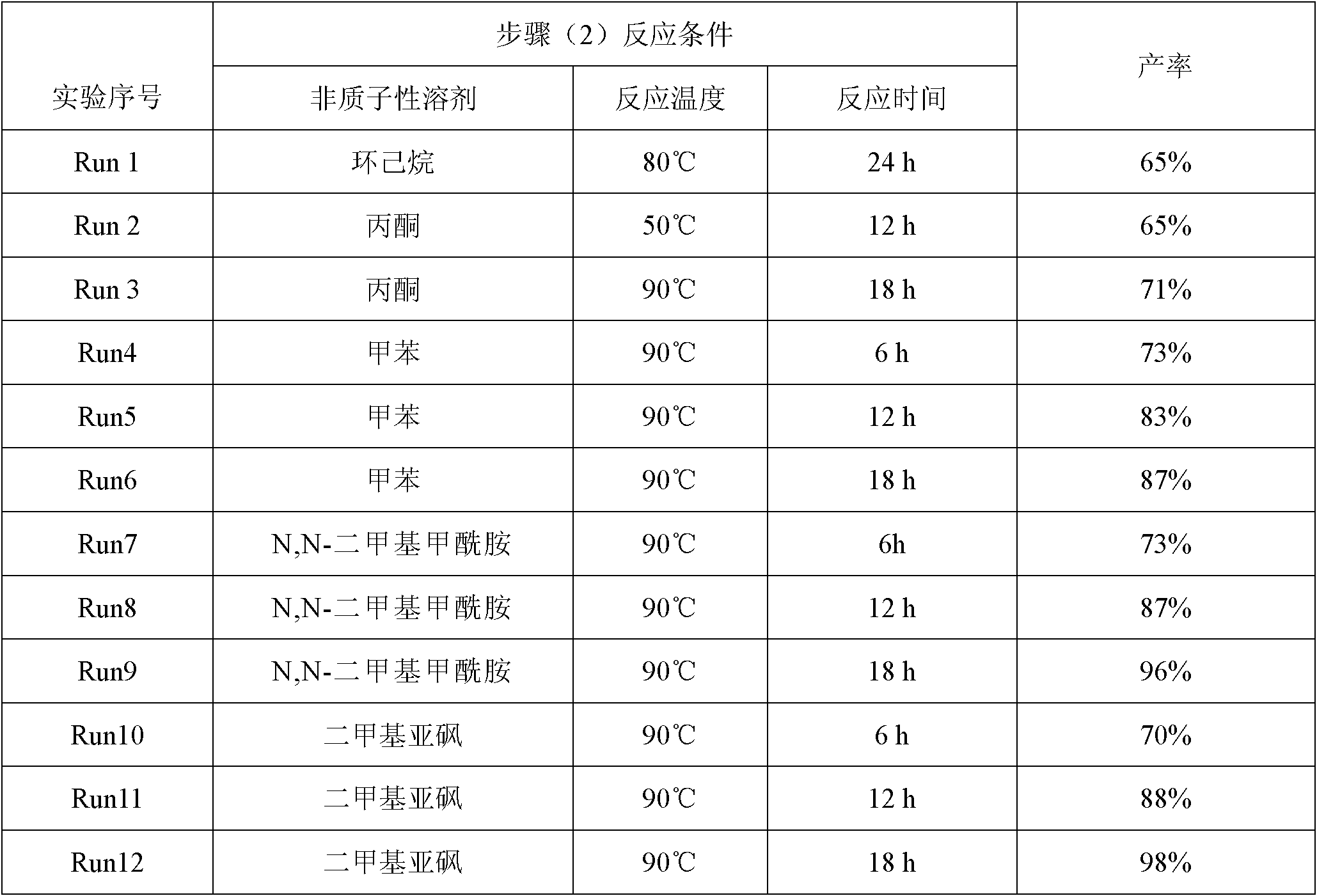

ActiveCN102584480ASolve the problem of slightly soluble in waterGood adhesionFertilizer mixturesN dimethylformamideWater soluble

The invention discloses a colloidal suspension agent for nitrogen fertilizer synergism, which is prepared from 2-chlorine-6-nitrapyrin, an emulsifier, calcium lignosulphonate, white carbon black, xanthan gum, N,N-dimethylformamide and water in a certain proportion. The nitrogen fertilizer can be sprayed to the particle surface after being screened by using the colloidal suspension agent along with good attachment effect, so that addition of the colloidal suspension agent before nitrogen fertilizer granulation is avoided, so that waste is reduced, and production cost is reduced; and the defect that 2-chloride-6-trichloromethylpyridine is slightly soluble is overcome, so that the colloidal suspension agent can be applied to nitrogen-containing water-soluble fertilizer.

Owner:SHANDONG HUIMENG BIO TECH CO LTD

Slow-release composite material as well as preparation method and application thereof

PendingCN108794182AAchieve friendlyReduce manufacturing costFertilisers by pryogenic processesAgriculture gas emission reductionCompound aOrganic matter

The invention provides a slow-release composite material. The slow-release composite material is prepared by compounding a first inorganic layer with a second inorganic layer through an organic matter, wherein the organic matter is a binding agent. According to the slow-release composite material provided by the invention, the raw materials are green and environment-friendly materials, so that theslow-release composite material is free of obvious residues in the soil and achieves environmental friendliness; the slow-release composite material can be used as a coating material; an inhibitor iscovered in the composite material, so that the loss of high-volatility effective components such as nitrapyrin is inhibited, and the storage stability is improved.

Owner:科丰兴泰(杭州)生物科技有限公司

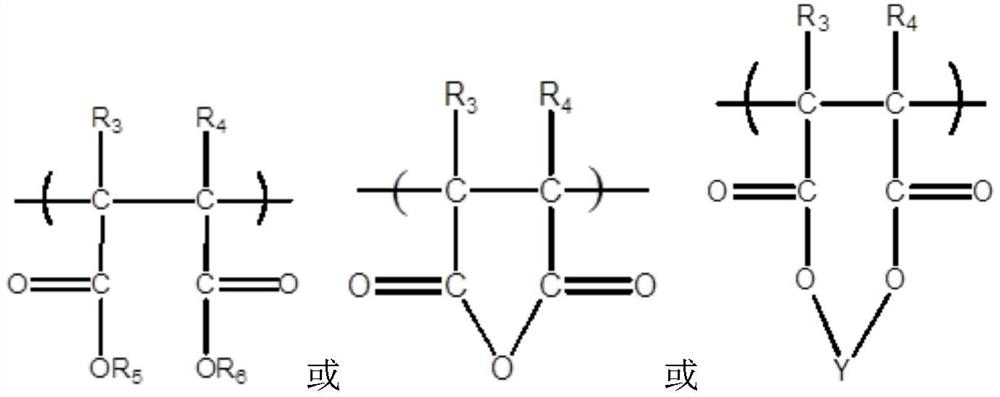

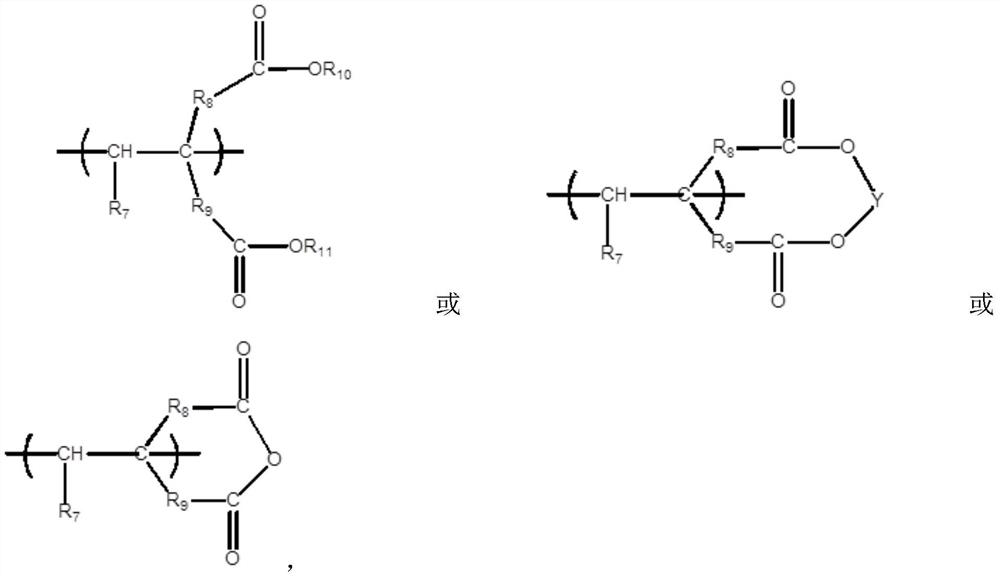

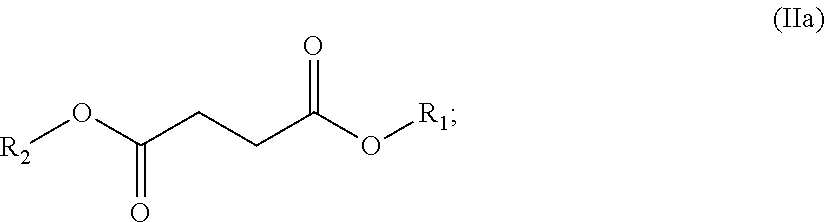

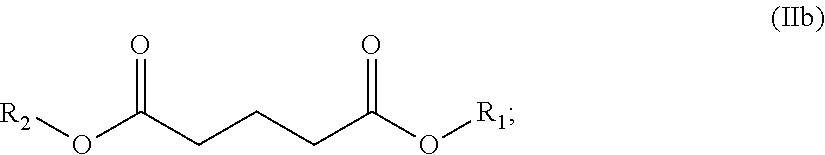

Nitrapyrin compositions for enhancing nitrogen nutrient use efficiency and improving plant growth

The presently disclosed subject matter is directed to nitrapyrin complexes and syntheses thereof finding particular utility in agricultural uses, e.g., directly applied to soil, or in combination with fertilizers to increase nutrient uptake and to inhibit nitrification and urease hydrolysis. More particularly, the subject matter is directed to nitrapyrin complexes, preferably containing specific types of carboxylic and sulfonate repeat units. Other uses of the nitrapyrin complexes and compositions containing nitrapyrin complexes are also disclosed.

Owner:美国维德赛生命科学有限公司

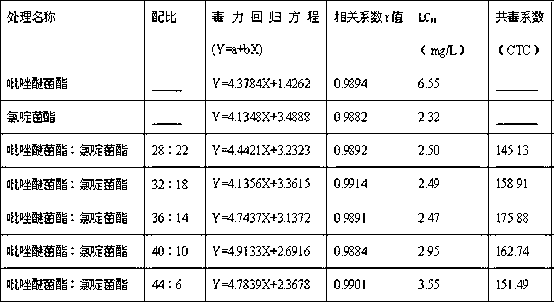

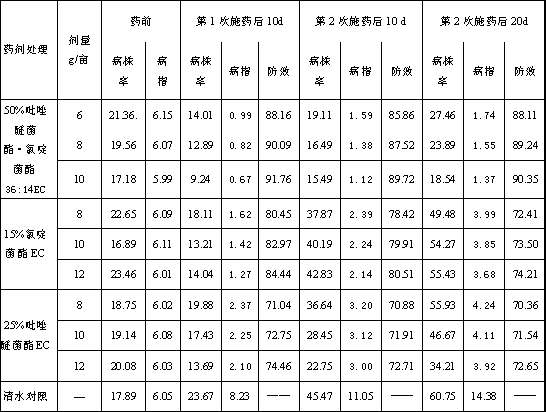

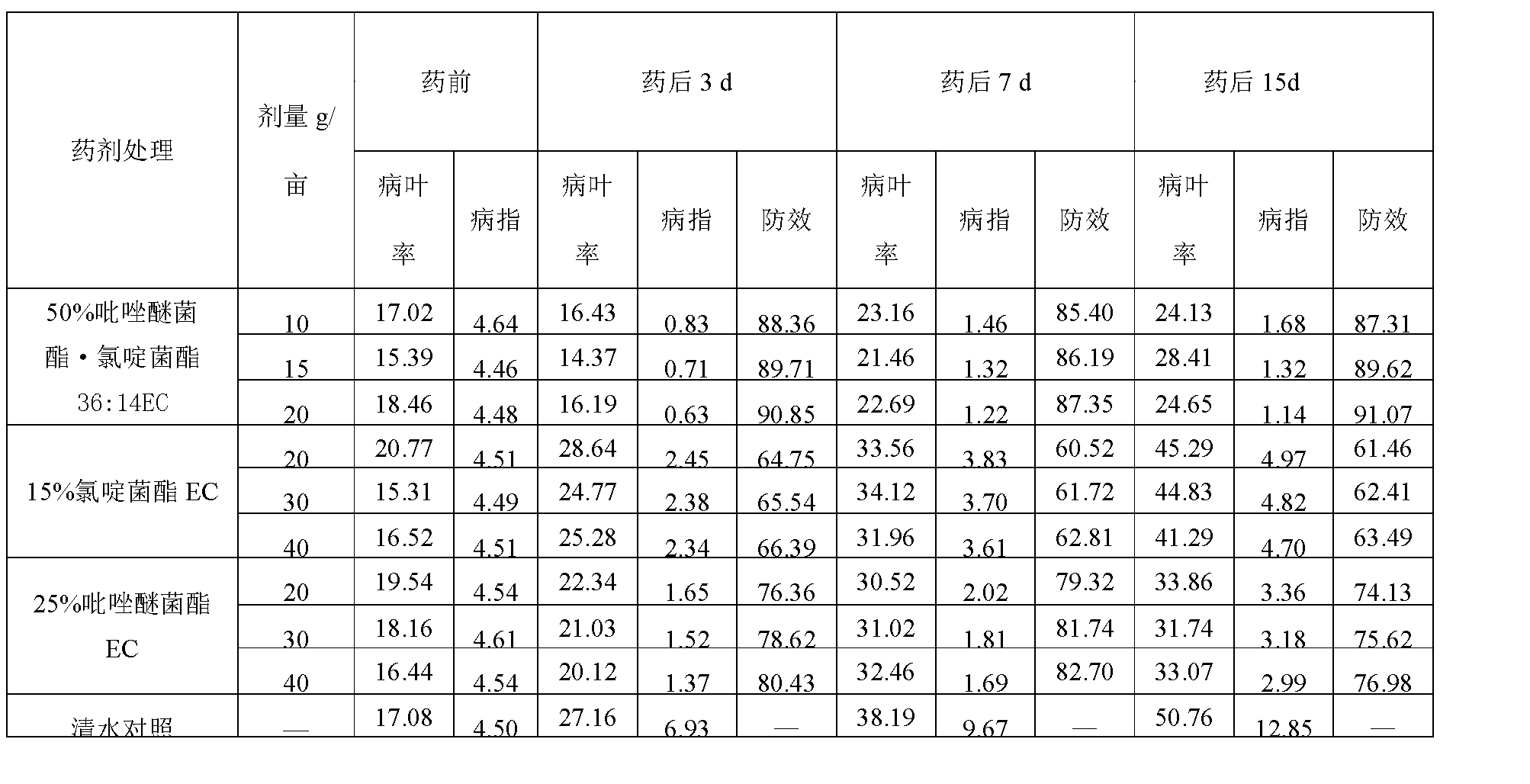

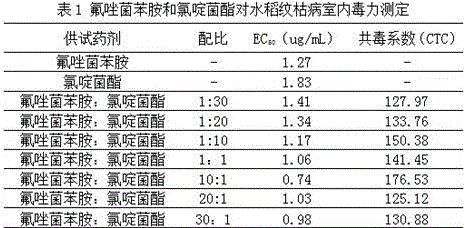

Sterilization composition containing pyraclostrobin and nitrapyrin bacteria ester

InactiveCN103004820ASynergistic effect is obviousDelay key drug resistanceBiocideFungicidesSuspending AgentsBiology

The invention relates to a sterilization composition containing pyraclostrobin and nitrapyrin bacteria ester, and the effective ingredients are the pyraclostrobin and the nitrapyrin bacteria ester in a compound way. The mass ratio of the pyraclostrobin to the nitrapyrin bacteria ester is (1-80):(80-1), and in the preparation, the total mass of the effective ingredients (the pyraclostrobin and the nitrapyrin bacteria ester) is 1%-80% of the total mass of the whole preparation, and the balance is auxiliary components allowed to be used and acceptable in a pesticide. A pesticide formulation which can be prepared by using the sterilization composition can be milk oil, a suspending agent, wettable powder, a water dispersible granule, emulsion in water and microemulsion. The sterilization composition is mainly used for preventing and curing wheat powdery mildew, rice blast, ustilaginoidea virens, cucurbites powdery mildew, tomato powdery mildew, apple rust, watermelon anthracnose and flower powdery mildew, and has good preventing and curing effects on cucumber downy mildew, macrophoma musae and leaf spot diseases.

Owner:HAILIR PESTICIDES & CHEM GRP

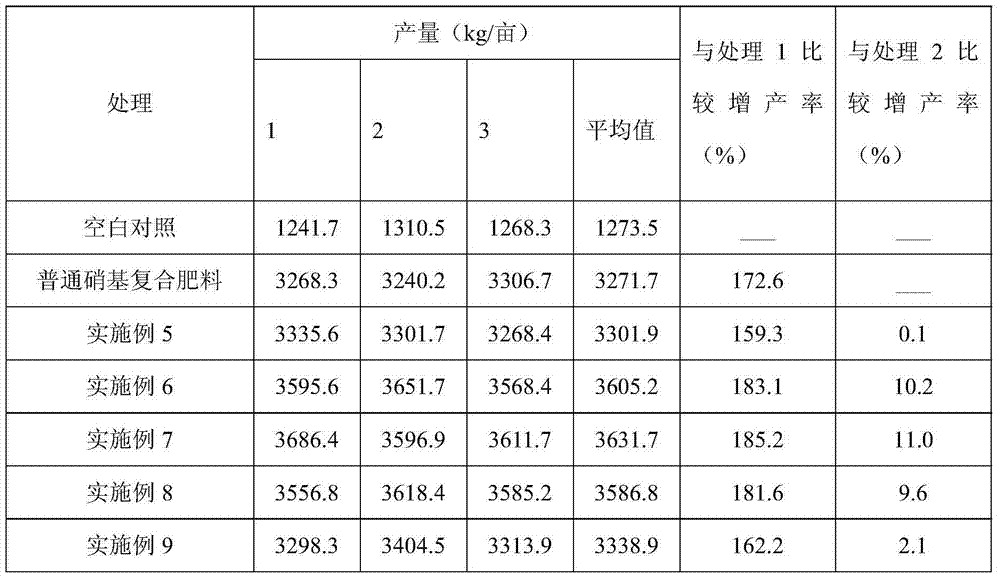

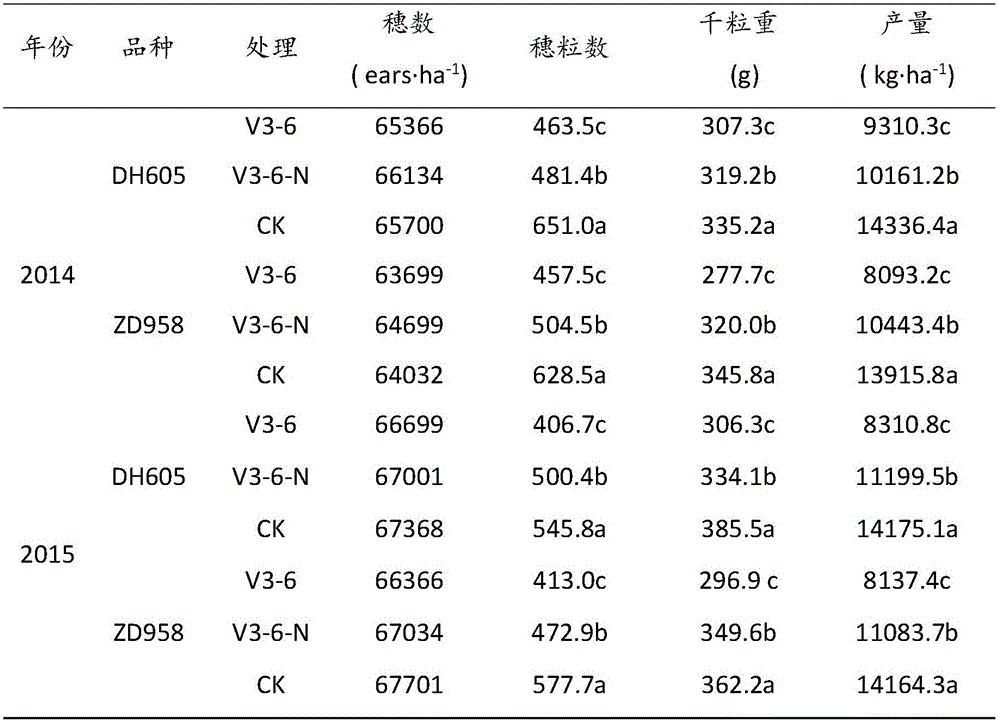

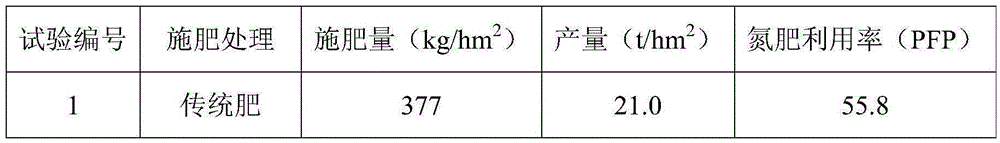

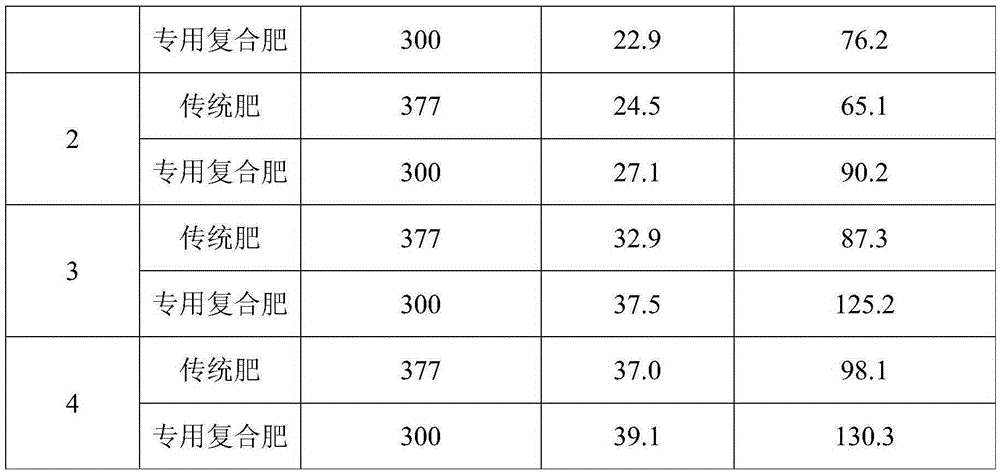

Corn planting method based on fertilizer applying treatment and capable of effectively adjusting and controlling waterlogging stress

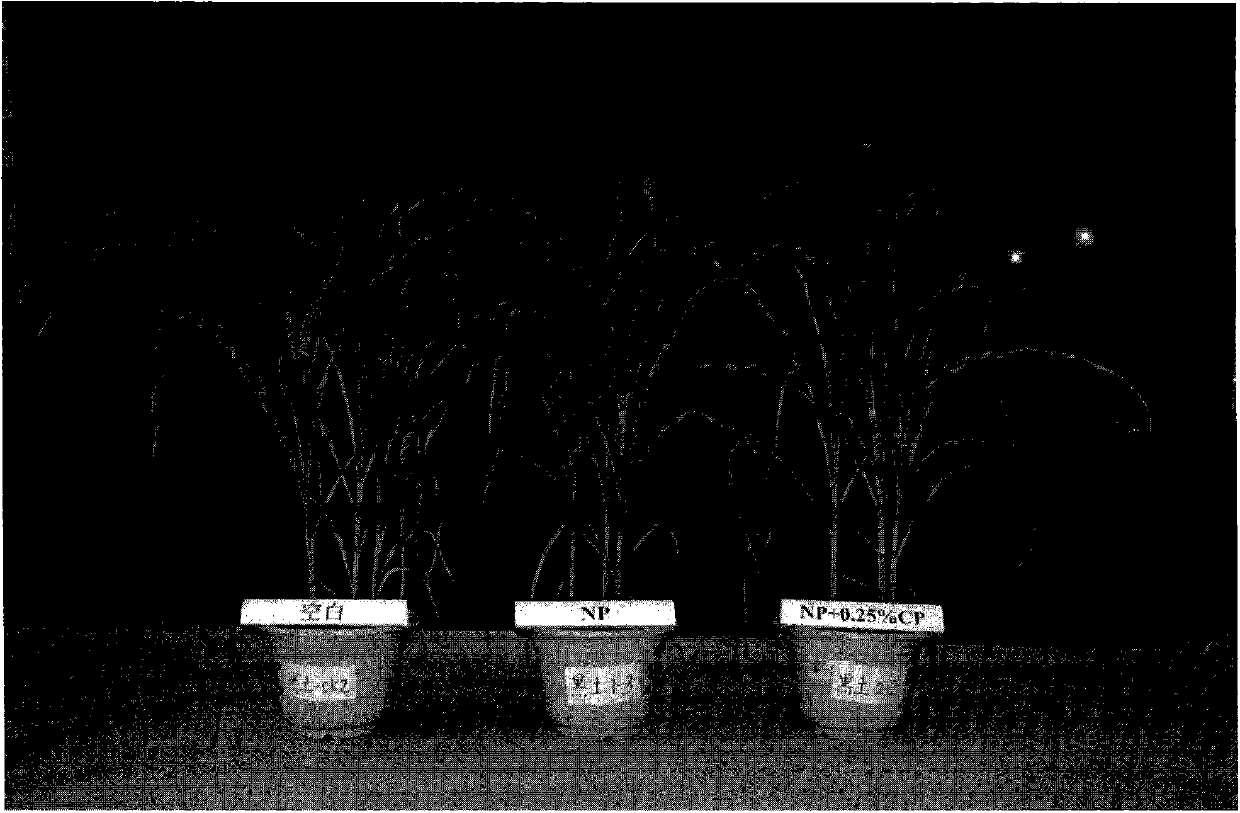

InactiveCN106034633AReduce outputIncrease productionFertilising methodsPlant cultivationPhosphate fertilizerMoisture

The invention discloses a corn planting method based on fertilizer applying treatment and capable of effectively adjusting and controlling waterlogging stress. The corn planting method comprises the following steps of performing fine soil preparation before sowing, and holding soil moisture; performing sowing in June, wherein the planting density is 67500 plants / hm<2>, according to the yield level of 12000kg / hm<2>, applying 210kg / hm<2> of N, 84kg / hm<2> of P2O5 and 168kg / hm<2> of K2O, and before the N, the P2O5 and the K2O are applied, uniformly mixing the N, the P2O5, the K2O and nitrapyrin (2-chloro-6-trichloromethylpyridine, nitrapyrin) for accompanying applying; separately applying 40% of nitrogenous fertilizers at a jointing stage and 60% of the nitrogenous fertilizers at a large trumpet stage, and applying all phosphate fertilizers and potash fertilizers once before sowing; performing furrowing at positions of 10-15cm away from corn planting rows for applying fertilizers; and performing field management according to the level of high-yield fields. After the fields are flooded in water, topdressing of urea with the nitrapyrin is performed, so that notable increase of yield is facilitated.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

High-yield slow-release selenium-rich and calcium-rich mixed fertilizer

InactiveCN106396986APromote growthImprove survival rateCalcareous fertilisersAnimal corpse fertilisersEggshellSolvent

The invention discloses a high-yield slow-release selenium-rich and calcium-rich mixed fertilizer. The high-yield slow-release selenium-rich and calcium-rich mixed fertilizer comprises, by weight, 28-40 parts of inorganic nitrogen fertilizers, 35-50 parts of organic nitrogen fertilizers, 5-8 parts of phosphorus pentoxide, 3-5 parts of potassium oxide, 0.1-2 parts of Na2B4O7 10H2O, 0.5-1 part of 2-chlorine-6-nitrapyrin, 0.5-1 part of trace elements, 30-40 parts of eggshell powder, 20-30 parts of corn cobs, 20-30 parts of rice bran and wheat bran, 1-3 parts of gypsum powder, 1-2 parts of shell fossil, 20-25 parts of ginkgo leaf powder, 30-40 parts of fish meal, 10-20 parts of bean pulp, 10-20 parts of straw, 1-2 parts of ionized calcium solvents, 0.5-0.8 part of nano-selenium powder and 10-150 parts of water. The high-yield slow-release selenium-rich and calcium-rich mixed fertilizer has the advantages that different types of calcium are mixed with one another, selenium is added into the calcium, the organic nitrogen fertilizers and the inorganic nitrogen fertilizers are mixed with one another, and the high-yield slow-release selenium-rich and calcium-rich mixed fertilizer is reasonable in proportion and beneficial to excellent growth of crops; the high-yield slow-release selenium-rich and calcium-rich mixed fertilizer can be applied to seeds, accordingly, the seeds are easy to germinate, can sprout neatly and are high in survival rate, and calcium and selenium in the crops can be increased by 1.5-1.8 times.

Owner:镇江常青园林工程有限公司

Colloidal suspension agent for nitrogen fertilizer synergism and application thereof

ActiveCN102584480BSolve the problem of slightly soluble in waterGood adhesionFertilizer mixturesN dimethylformamideChloride

The invention discloses a colloidal suspension agent for nitrogen fertilizer synergism, which is prepared from 2-chlorine-6-nitrapyrin, an emulsifier, calcium lignosulphonate, white carbon black, xanthan gum, N,N-dimethylformamide and water in a certain proportion. The nitrogen fertilizer can be sprayed to the particle surface after being screened by using the colloidal suspension agent along with good attachment effect, so that addition of the colloidal suspension agent before nitrogen fertilizer granulation is avoided, so that waste is reduced, and production cost is reduced; and the defect that 2-chloride-6-trichloromethylpyridine is slightly soluble is overcome, so that the colloidal suspension agent can be applied to nitrogen-containing water-soluble fertilizer.

Owner:SHANDONG HUIMENG BIO TECH CO LTD

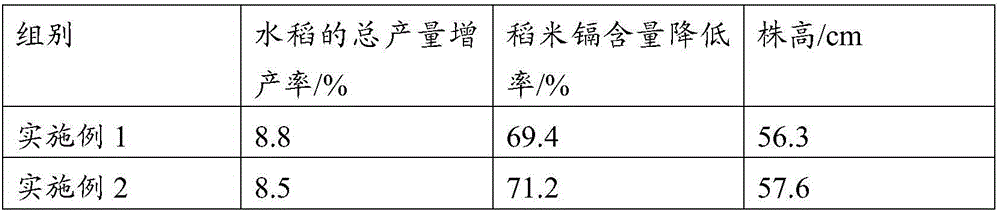

Coated slow-release fertilizer for paddy rice

InactiveCN107903109AEffective growth and developmentEffectively promote growth and developmentCalcareous fertilisersAnimal corpse fertilisersRapeseedMagnesium ammonium phosphate

The invention discloses coated slow-release fertilizer for paddy rice and a preparation method thereof. The coated slow-release fertilizer comprises a fertilizer matrix and a coating agent coating theouter surface of the fertilizer matrix, wherein the fertilizer matrix comprises nitrapyrin crystal urea, oxalyl urea, potassium-magnesium sulfate fertilizer, potassium dihydrogen phosphate, potassiumchloride, calcium chloride, sodium selenite, borate, molybdate, manganese sulfate, zinc ammonium phosphate, iron ammonium phosphate, magnesium ammonium phosphate, rapeseed meal, sunflower seed meal,tea seed meal, xylitol residues, edible fungus residues, shrimp shell powder, seaweed powder, potassium fulvate, rooting powder, naphthalene acetic acid, potassium citrate, chitosan and plant extraction agent; the coating agent comprises oxidized starch, glycerin, sodium alginate, urea-formaldehyde resin, cotton fibers, phosphoric acid, sodium lactate, acrylic urethane and clay. The coated slow-release fertilizer for paddy rice is high in fertilizer efficiency, lasting in effect, capable of effectively increasing the yield of the paddy rice and capable of improving the quality of the paddy rice.

Owner:来安县薜必英家庭农场

Water-soluble fertilizer for improving soil quality and preparation method of water-soluble fertilizer

InactiveCN107522578AAchieve utilizationMaximize UtilizationCalcareous fertilisersOrganic fertilisersBacillus licheniformisAlcohol sugars

The invention provides a water-soluble fertilizer for improving soil quality and a preparation method of the water-soluble fertilizer, and belongs to the technical field of water-soluble fertilizers. The water-soluble fertilizer consists of the following components: calcium carbonate, potassium silicate, calcium sulfate, sodium sulfate, ethylenediamine tetraacetic acid, bacillus licheniformis, bacillus subtilis, xylogen, potassium sulfate, urea, 2-chloro-6-nitrapyrin, polyacrylamide, citric acid, compound sugar alcohol, alanine and water. The preparation method is simple and efficient, is low in cost, and has high commercial use value. By the water-soluble fertilizer for improving soil quality, absorption of crops to cadmium can be inhibited; if the water-soluble fertilizer for improving soil quality is irrigated to plants in a dripping manner or sprayed to the plants, absorption and enrichment of the cadmium and mercury in the plants can be reduced, the water-soluble fertilizer can also be uniformly distributed in soil of the roots of the plants by integration of water and fertilizer, requirements of the plants in a growth period to various nutrients can be met, growth of the plants is promoted, the quality of the plants is improved, and maximization of utilization of the fertilizer is realized.

Owner:AMB NANJING BIOTECH CO LTD

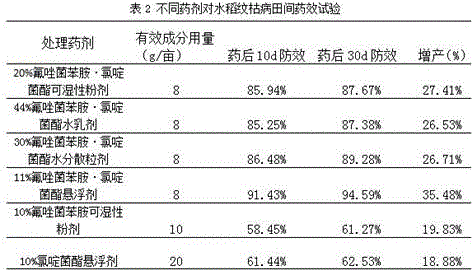

Sterilizing combination containing triflumizole aniline and nitrapyrin azoxystrobin

ActiveCN106135243ADelay drug resistanceGood synergyBiocideDead animal preservationMedicineAzoxystrobin

The invention discloses a sterilizing combination containing triflumizole aniline and nitrapyrin azoxystrobin. The weight ratio of the triflumizole aniline to the nitrapyrin azoxystrobin is 1:30-30:1, and the weight percentage of active components in the combination is 5-80%. The sterilizing combination is high in sterilizing activity, generation of the drug resistance of pathogenic bacteria can be delayed, drug dosage can be decreased, and rice sheath blight disease prevention and treatment effects are particularly remarkable.

Owner:中新科农(山东)生态农业有限公司

Non-corrosive nitrification inhibitor polar solvent formulation

ActiveUS20160332930A1Enhances crop performanceImprove croppingNitrogenous fertilisersAgriculture gas emission reductionNitrification inhibitorsSolvent

This invention relates to stable liquid formulations of the nitrification inhibitor nitrapyrin comprising polar solvents that are stabilized with small amounts of compounds which help to reduce the tendency of polar solutions of nitrapyrin to corrode metal surfaces. Many of the formulations disclosed herein exhibit useful physical, chemical, and bioactive properties including reduced levels of corrosion when in contact with ferrous metals.

Owner:RHODIA OPERATIONS SAS +1

Special compound fertilizer for spinach

InactiveCN107759283AImprove qualityImprove fertilizer efficiencyBio-organic fraction processingAlkali orthophosphate fertiliserSulfatePhosphate

The invention provides a special compound fertilizer for spinach. The fertilizer is prepared from the following raw materials in parts by weight: 22-30 parts of urea, 10-20 parts of monoammonium phosphate, 10-15 parts of a potassium fertilizer, 1-2 parts of a 2-chloro-6-nitrapyrin, 0.5-2 parts of ferric sulfate, 0.5-2 parts of calcium ammonium nitrate and 30-45 parts of an organic active fertilizer. The preparation method of the fertilizer provided by the invention is simple, a purpose of increasing output and yield can be achieved, the utilization ratio of nutrients is improved, and the physical and chemical properties of soil are improved.

Owner:吴绍玲

Synergist for microelement water-soluble fertilizer and preparation method thereof

ActiveCN103772052AUniform and stable suspensionWon't clogFertilizer mixturesOrganic solventWater soluble

The invention provides a synergist for microelement water-soluble fertilizer and a preparation method thereof, relates to a composition and particularly relates to a synergist for the water-soluble fertilizer and a preparation method thereof. Since existing 2-chlorin-6-nitrapyrin needs to be processed into dosage forms such as missible oil when used together with water, lots of organic solvents are needed and a production technology is complicated. The synergist provided by the invention can overcome the problems. The synergist is the mixture of 2-chlorin-6-nitrapyrin, cyclophosphinylidyne triamine (CHTP) and brown coal humic acid. The preparation method comprises the following steps: sequentially putting 2-chlorin-6-nitrapyrin, cyclophosphinylidyne triamine (CHTP) and brown coal humic acid in a reactor, stirring, uniformly mixing and grinding in a jet mill, thus obtaining the synergist for the microelement water-soluble fertilizer. The preparation method is mainly used for preparing the synergist for the microelement water-soluble fertilizer.

Owner:张彬

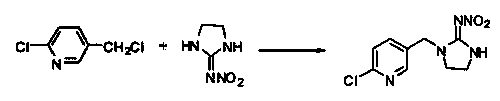

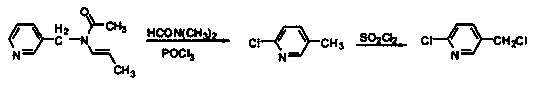

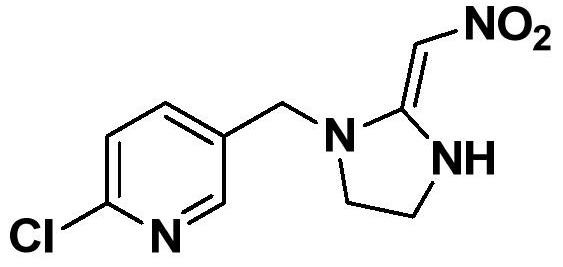

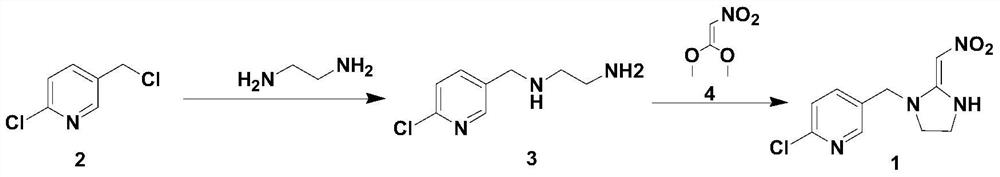

Synthesis method of imidacloprid as insecticide

The invention discloses a synthesis method of imidacloprid as an insecticide. The synthesis method comprises the following steps: (1) by taking N-benzyl-N-propenylacetamide as a raw material, enabling the N-benzyl-N-propenylacetamide and phosphorus oxychloride to react in a solvent dimethylformamide at the temperature of 100 DEG C for 14-16h while stirring, then, further chloridizing in thionyl chloride, cooling, keeping the temperature at 15-20 DEG C, and performing suction to remove unreacted phosphorus oxychloride in vacuum to obtain 2-chloro-5-nitrapyrin; and (2) dissolving the 2-chloro-5-nitrapyrin and imidazolidine into acetonitrile, adding an acid absorbent, and carrying out heating reflux for 5h in the presence of CsCl to obtain the product, i.e., 1-(6-chloro-3-pyridinylmethyl)-N-nitroimidazole-2-imide. The method disclosed by the invention is short in route, high in yield and not easy to generate three wastes.

Owner:JIANGSU KESHENG CROP TECH

Nitrification inhibitor compositions and methods of making thereof

ActiveUS10501383B2Agriculture gas emission reductionSolid/semi-solid fertilisersNitrification inhibitorsNitrapyrin

An improved nitrification inhibitor composition comprising UFP particles and a nitrification inhibitor, and optionally other components, is used as an additive for liquid and solid fertilizers, typically containing urea. The nitrification inhibitor particularly can be nitrapyrin and / or DMPP. Methods of making the compositions and their use are also disclosed.

Owner:KOCH AGRONOMIC SERVICES LLC

Long-acting and quick-acting combined special compound fertilizer for fruits and vegetables in South China

InactiveCN105272779AMeet quick-acting needsInhibit or delay nitrificationAgriculture gas emission reductionFertilizer mixturesElutionNitrate nitrogen

The invention discloses long-acting and quick-acting combined special compound fertilizer for fruits and vegetables in South China. The long-acting and quick-acting combined special compound fertilizer is prepared from, by weight, 7.0-7.5 parts of nitrate nitrogen, 7.5-8.0 parts of ammonium nitrogen, 7 parts of P2O5 and 21 parts of K2O. 2-chlorine-6-nitrapyrin serves as nitrification inhibitor, and the additive amount of 2-chlorine-6-nitrapyrin accounts for 0.5% to 1.0% of ammonium nitrogen. The nitrification inhibitor is used for prolonging the fertilizer efficiency of ammonium nitrogen, a nitrate nitrogen source is mixed and added, the needs of the fruits and vegetables for nitrogen nutrition of different forms can be met, yield increasing and quality improving are achieved, long acting and quick acting can be combined, the nitrogen use efficiency can be improved, and nitrate elution can be reduced. The long-acting and quick-acting combined special compound fertilizer is suitable for South China and other areas with high rainfall capacity, can be used as base fertilizer, can also be applied for topdressing, and has high economic, social and ecological benefits.

Owner:INST OF VEGETABLES GUANGDONG PROV ACAD OF AGRI SCI +1

Ammonium nitrogen stabilized nitric phosphate and preparation method thereof

Ammonium nitrogen stabilized nitric phosphate. Common nitric phosphate is mixed with an inhibitor, wherein the inhibitor is DCD or 2-chloro-6-trichloromethylpyridine (Nitrapyrin). When the DCD is employed as the inhibitor, the ammonium nitrogen stabilized nitric phosphate is prepared by mixing 100 parts by weight of the nitric phosphate and 1.3 parts by weight of the DCD; when the 2-chloro-6-trichloromethylpyridine (Nitrapyrin) is employed as the inhibitor, the ammonium nitrogen stabilized nitric phosphate, in moisture soil, is prepared by mixing 100 parts by weight of the nitric phosphate and 0.13 part by weight of the Nitrapyrin; and when the 2-chloro-6-trichloromethylpyridine (Nitrapyrin) is employed as the inhibitor, the ammonium nitrogen stabilized nitric phosphate, in black soil, is prepared by mixing 100 parts by weight of the nitric phosphate and 0.065 part by weight of the Nitrapyrin. By means of the ammonium nitrogen stabilized nitric phosphate, a use efficiency of the nitric phosphate can be increased and pollutions of the fertilizer on body of water can be reduced.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

A kind of synthetic method of 2-chloro-5-((2-(nitromethylene)imidazolin-1-yl)methyl)pyridine

The invention provides a synthetic method of 2-chlorine-5-((2-(nitromethylene)imidazoline-1-yl)methyl)pyridine. The method comprises the steps of taking 2-chlorine-5-nitrapyrin as a starting material, enabling the starting material to be subjected to a substitution reaction with ethylenediamine in the presence of a phase transfer catalyst and alkali to generate chloropyridine ethylenediamine, adding 1,1-dimethoxy-2-nitroethylene into the same reaction vessel, performing a reflux reaction, performing after-treatment to prepare a target product, i.e., the 2-chlorine-5-((2-(nitromethylene)imidazoline-1-yl)methyl)pyridine is synthesized by a one-pot method. By adopting the synthetic method, the target product of high content can be obtained, an intermediate of the first-step reaction does not need separation and purification, the two-step synthesis unit operation is completed in the same reaction vessel, the equipment utilization rate is high, the after-treatment is simple in process, the operation conditions are mild, thus a prospect of industrial production is achieved.

Owner:SHANGHAI SHENGNONG PESTICIDE

Non-corrosive nitrification inhibitor polar solvent formulation

ActiveUS10173943B2Improve performanceIncrease crop yieldNitrogenous fertilisersAgriculture gas emission reductionNitrification inhibitorsSolvent

This invention relates to stable liquid formulations of the nitrification inhibitor nitrapyrin comprising polar solvents that are stabilized with small amounts of compounds which help to reduce the tendency of polar solutions of nitrapyrin to corrode metal surfaces. Many of the formulations disclosed herein exhibit useful physical, chemical, and bioactive properties including reduced levels of corrosion when in contact with ferrous metals.

Owner:DOW AGROSCIENCES LLC +1

Preparation method for silica gel-loaded aminomethylpyridine chelating resin for deep copper removal

InactiveCN102441367BImprove adsorption capacityIncrease loadOther chemical processesSilica gelChelating resin

The present invention relates to a preparation method for a silica gel-loaded aminomethylpyridine chelating resin for deep copper removal. According to the method, a silicane coupling agent reacts with 2-aminomethylpyridine under an anhydrous condition to generate an aminomethylpyridine modified silicane coupling agent; the aminomethylpyridine modified silicane coupling agent is grafted onto the surface of the activated silica gel. With the method of the present invention, the loading and the metal ion adsorption capacity of the functional groups of the chelating resin are effectively improved; the synthetic route is simple and economical. In addition, in the existing synthetic route, when silicon dioxide with the surface modification of the amino groups reacts with nitrapyrin to prepare the chelating resin, the alkality of the reaction system is high (the pH value is more than 11), and the silicon dioxide is dissolved, or the alkality of the reaction system is low (the pH value is less than 10), the nucleophilic substitution reaction efficiency between the nitrapyrin functional group and the amino group is low, and the loading of the functional group is not high. With the method of the present invention, the problems in the existing synthetic route are avoided.

Owner:CENT SOUTH UNIV

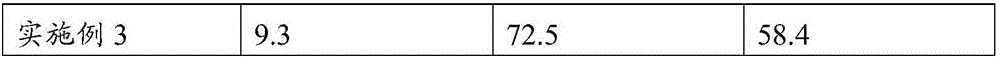

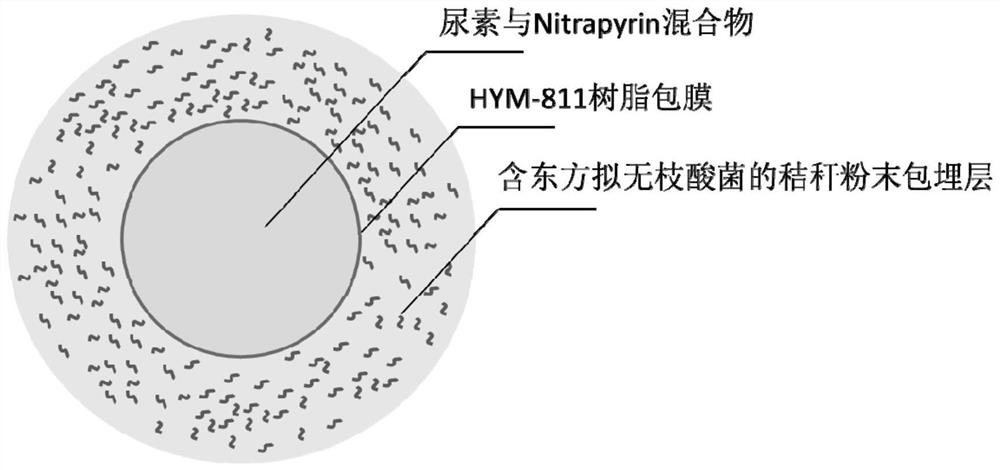

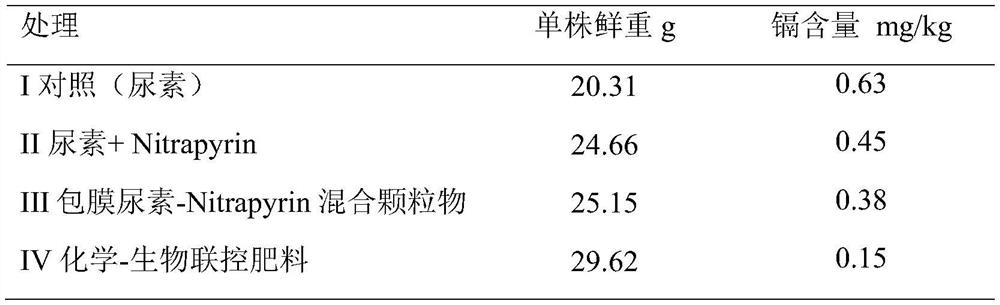

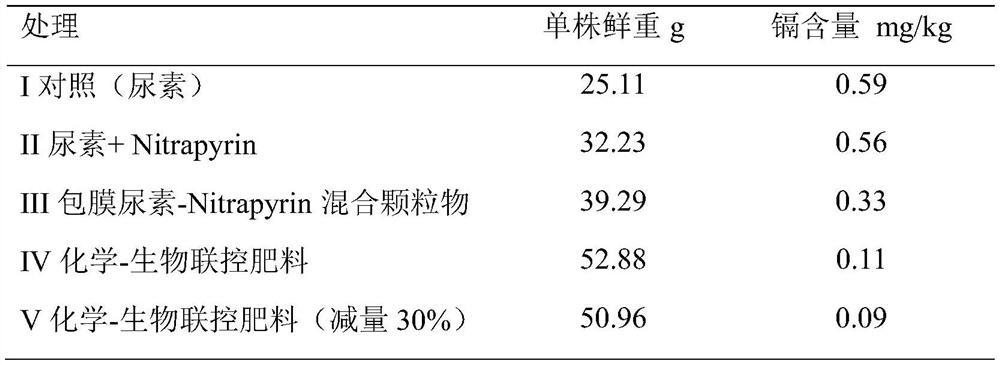

Chemical-biological joint control fertilizer capable of reducing cadmium accumulation of vegetables and increasing yield of vegetables as well as preparation and application of chemical-biological joint control fertilizer

ActiveCN112624881AReduce cadmium contentIncrease productionOrganic fertilisersSolid/semi-solid fertilisersBiotechnologyEngineering

The invention discloses a chemical-biological joint control fertilizer capable of reducing cadmium accumulation of vegetables and increasing the yield of the vegetables as well as preparation and application of the chemical-biological joint control fertilizer. The chemical-biological joint control fertilizer is in a solid granule shape, and sequentially comprises a urea-Nitrapyrin mixture positioned in the center of the granule, a coating film coated outside the urea-Nitrapyrin mixture and an embedding layer which is positioned outside the coating film and contains Amycolatopsis orientalis from inside to outside. The chemical-biological joint control fertilizer can efficiently reduce and control cadmium accumulation of crops in a long-acting manner, and can also increase the crop yield at the same time.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com