Slow-release composite material as well as preparation method and application thereof

A composite material and slow-release fertilizer technology, applied in the field of composite materials, can solve the problems of inability to form a dense slow-release film, cannot prevent the volatilization of chloride, and easy loss of nitrification inhibitors, so as to improve storage stability and storage stability The effect of high reliability and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

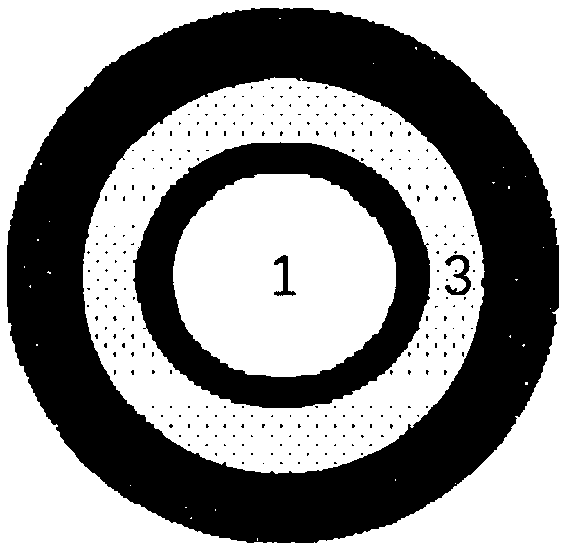

Image

Examples

Embodiment 1

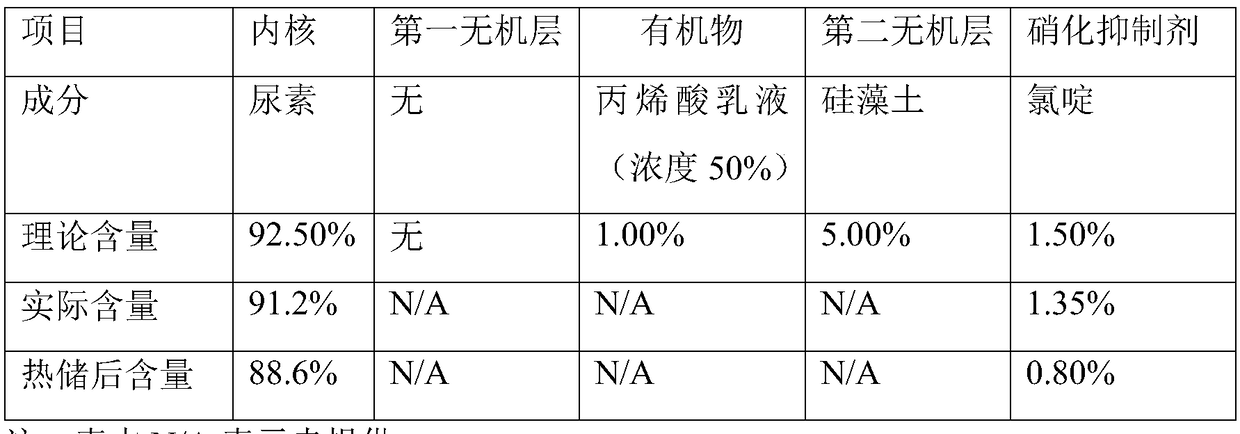

[0045] Example 1 Preparation of slow-release urea granular fertilizer of chloridine nitration inhibitor

[0046] (1) Urea fertilizer is the core. Weigh 2 kg of urea with a particle diameter of 3mm, add it to a drum-type coating machine with a diameter of 40cm-50cm, and rotate at a constant speed of 30rpm-500rpm. 200 g of ethyl chloropyridine solution with a concentration of 35 wt% was uniformly applied on the surface of the particles, and the rotation was continued to prevent agglomeration.

[0047] (2) Add 90g of 50-mesh diatomaceous earth pre-dried at 120°C into the drum of step (1) and stir well at 300rpm for 5 minutes to complete the inner coating (even if the fertilizer and inhibitor are coated In the first inorganic layer);

[0048] (3) Apply the organic matter to the drum in step (2), mix thoroughly for 5 minutes, then add 100 g of pre-dried 50 mesh diatomaceous earth, and continue to rotate for 5 minutes to obtain a slow-release fertilizer.

[0049] The slow-release fertilize...

Embodiment 2

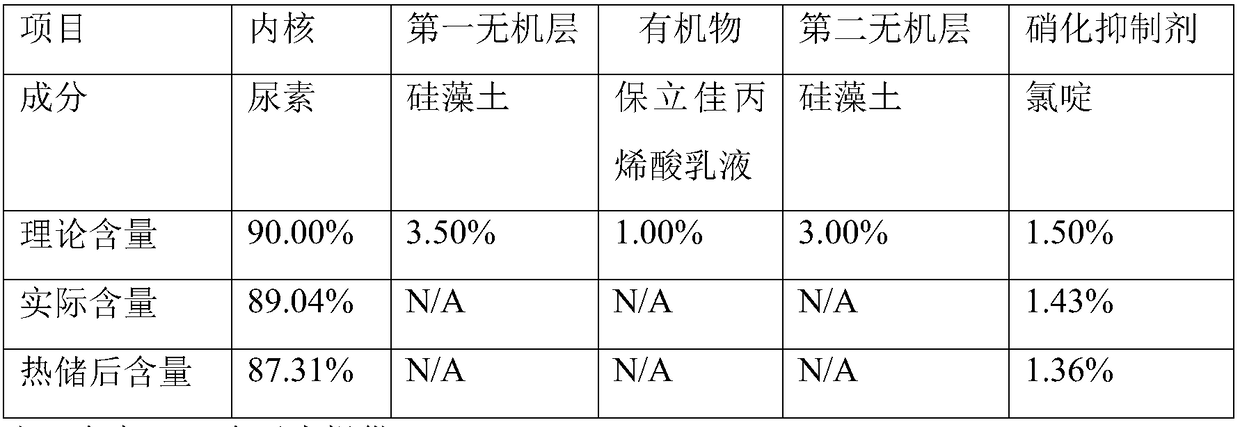

[0080] Example 2 Preparation of slow-release urea granular fertilizer containing nitrification inhibitor and urease inhibitor

[0081] (1) Weigh 2kg of urea with a particle diameter of 3mm and 4g of nBPT into a drum-type coating machine with a diameter of 40cm-50cm, and rotate at a constant speed of 30rpm-70rpm. Apply 200g of a 30wt% chloropyridine acetone solution to the surface of the particles and continue to rotate to prevent agglomeration;

[0082] (2) Add 90g of 50-mesh diatomaceous earth pre-dried at 120°C into the drum of step (1) and stir it fully at 70rpm for 5 minutes to complete the inner coating (even if the fertilizer and inhibitor are coated In the first inorganic layer);

[0083] (3) Apply the organic matter to the drum of step (2), mix thoroughly for 5 minutes, then add 100 g of pre-dried 50 mesh diatomaceous earth, and continue to rotate for 5 minutes to obtain a slow-release fertilizer.

[0084] The slow-release fertilizer in step (3) is dried at 70°C to 100°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com