Production process of acetamiprid

A production process and acetamiprid technology, which is applied in the production process field of acetamiprid, can solve the problems of high consumption, high odor of monomethylamine, easy volatility and the like, and achieve the effects of less waste water, less three wastes, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

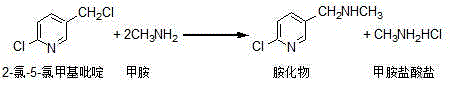

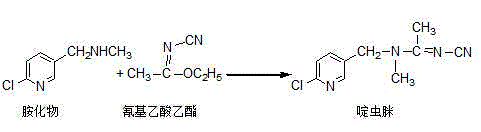

Method used

Image

Examples

Embodiment 1

[0018] The production technology of acetamiprid comprises the following steps:

[0019] a. Amination: At room temperature, add 5000L chloroform into the amination reaction kettle, turn on the cooling system, lower the temperature in the kettle to 3°C, and start inserting 200kg of monomethylamine gas into the chloroform solution under the liquid , and at this temperature, add 1000kg of 2-chloro-5-chloromethylpyridine dropwise to the reactor under normal pressure, and control the dropping rate to 4Kg / min, so that the reaction temperature does not exceed 20°C, keep the reaction for 4h, and take samples for analysis After passing the test, heat the reaction kettle to 45°C, drive out the excess methylamine dissolved in chloroform, pass the driven out methylamine into the absorption tank and absorb it with chloroform for the next batch of reactions, cool the material to room temperature, add water and stir 1h, standing for stratification, water layer wastewater to be treated, organi...

Embodiment 2

[0022] The production technology of acetamiprid comprises the following steps:

[0023] a. Amination: At room temperature, add 5000L chloroform into the amination reaction kettle, turn on the cooling system, lower the temperature in the kettle to 4°C, and start inserting 204kg of monomethylamine gas into the chloroform solution under the liquid , and at this temperature, add 1040 kg of 2-chloro-5-chloromethylpyridine dropwise to the reactor under normal pressure, and control the dropping rate at 5Kg / min, so that the reaction temperature does not exceed 20°C, keep the temperature for 5 hours, and take samples for analysis After passing the test, heat the reaction kettle to 46°C, drive out the excess methylamine dissolved in chloroform, pass the driven out methylamine into the absorption tank and absorb it with chloroform for the next batch of reactions, cool the material to room temperature, add water and stir 1h, standing for stratification, water layer wastewater to be treate...

Embodiment 3

[0026] The production technology of acetamiprid comprises the following steps:

[0027] a. Amination: At room temperature, add 5000L chloroform into the amination reaction kettle, turn on the cooling system, lower the temperature in the kettle to 4°C, and start inserting 208kg of monomethylamine gas into the chloroform solution under the liquid , and at this temperature, add 1080kg of 2-chloro-5-chloromethylpyridine dropwise to the reactor under normal pressure, control the dropping rate at 5Kg / min, keep the reaction temperature not exceeding 20°C, keep the reaction for 45h, and take samples for analysis After passing the test, heat the reaction kettle to 47°C, drive out the excess methylamine dissolved in chloroform, pass the driven out methylamine into the absorption tank and absorb it with chloroform for the next batch of reactions, cool the material to room temperature, add water and stir 1h, standing for stratification, water layer wastewater to be treated, organic layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com