Molybdenum disulfide/graphene (MoS2/rGo) lithium ion battery negative electrode material and preparation method of material

A lithium-ion battery and molybdenum disulfide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability, low cycle stability, and capacity loss, and achieve high specific capacity and strong operability , The method is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

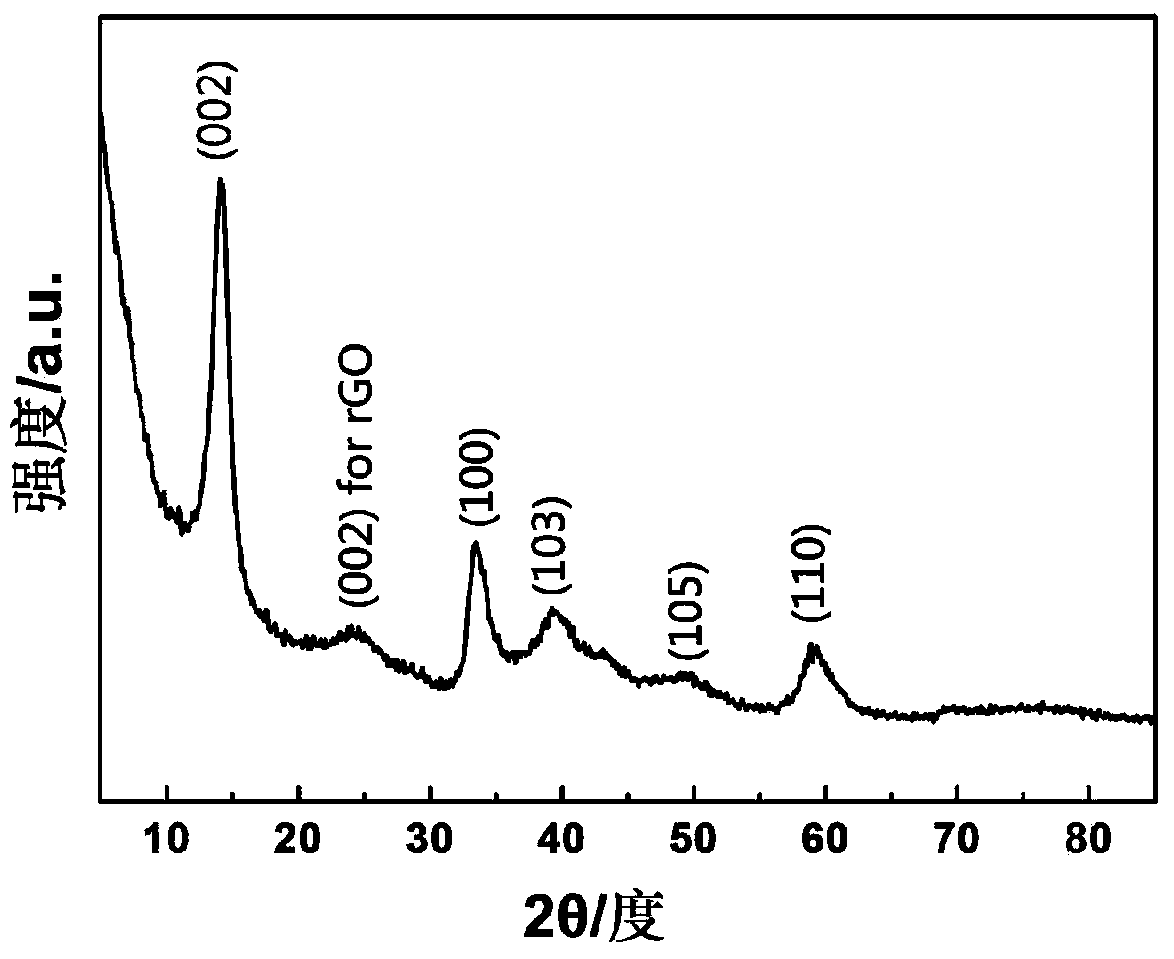

[0027] Molybdenum disulfide / graphene (MoS) of the present invention 2 / rGO) lithium ion battery negative electrode material and preparation method thereof, adopt hydrothermal method preparation, comprise the steps:

[0028] Step 1. Take sodium molybdate, thiourea, graphene oxide and deionized water 30ml to prepare MoS according to the molar ratio of 1:3.75~4.5:1~3 2 / rGO reaction raw materials;

[0029] Step 2, the MoS described in step 1 2 The reaction raw materials are put into a hydrothermal reaction kettle, and the hydrothermal reaction is carried out at 180-220°C for 23-25 hours to obtain MoS 2 / rGO black product;

[0030] Step 3, the MoS described in step 2 2 / rGO was filtered and washed, then placed in a vacuum drying oven, and dried at 60-90°C.

Embodiment 1

[0032] Step 1. Take 0.300g of sodium molybdate, 0.354g of thiourea, 0.014g of graphene oxide and 30ml of deionized water to prepare MoS 2 / rGO reaction raw materials;

[0033] Step 2, the MoS described in step 1 2 The reaction raw materials were put into a hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 180°C for 23h to obtain MoS 2 / rGO black product;

[0034] Step 3, the MoS described in step 2 2 / rGO was filtered and washed, then placed in a vacuum drying oven, and dried at 60-90°C.

Embodiment 2

[0036] The difference between this example and example 1 is that in step 1, sodium molybdate 0.300g, thiourea 0.400g, graphene oxide 0.028g and deionized water 30ml; in step 2, the reaction temperature is 200°C, and the reaction time is 24h; Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com