Novel rubber compound stuffing preparing method based on mercapto-alkene chemical reaction

A chemical reaction and composite filler technology, which is applied in the field of rubber fillers, can solve problems such as lack of synergistic effects, achieve good economic benefits and social effects, mild reaction conditions, and reduce surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

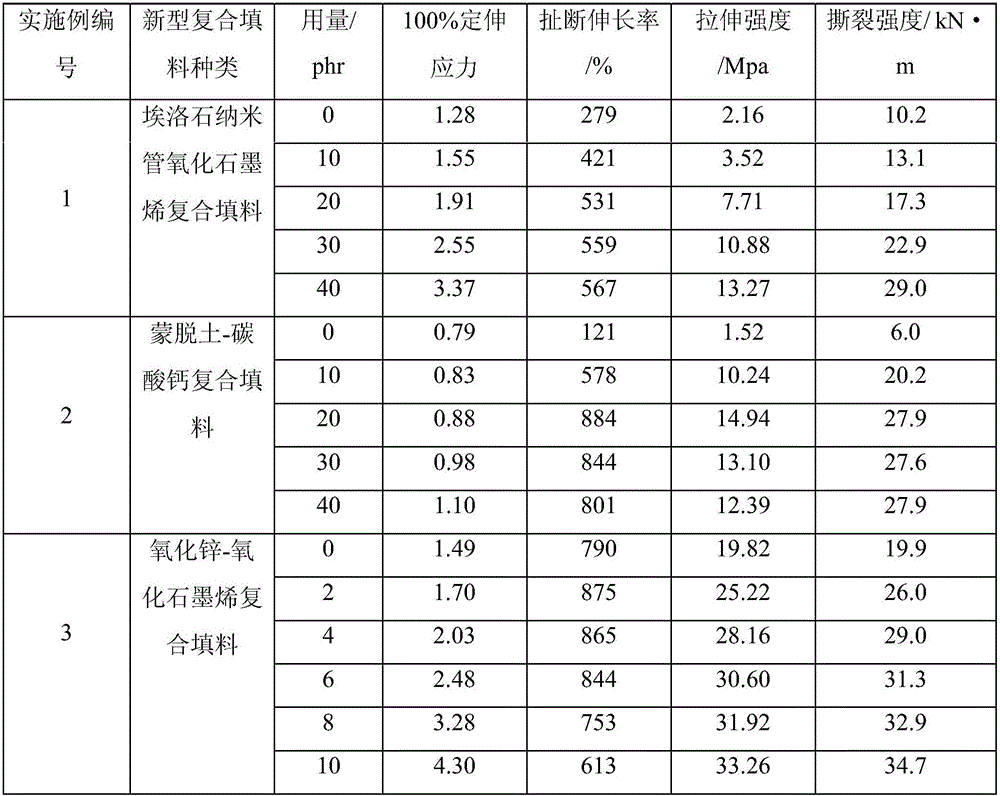

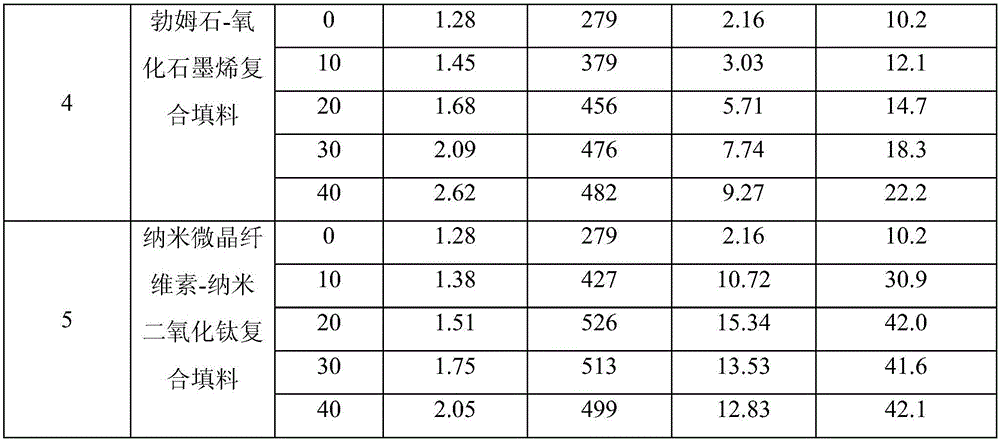

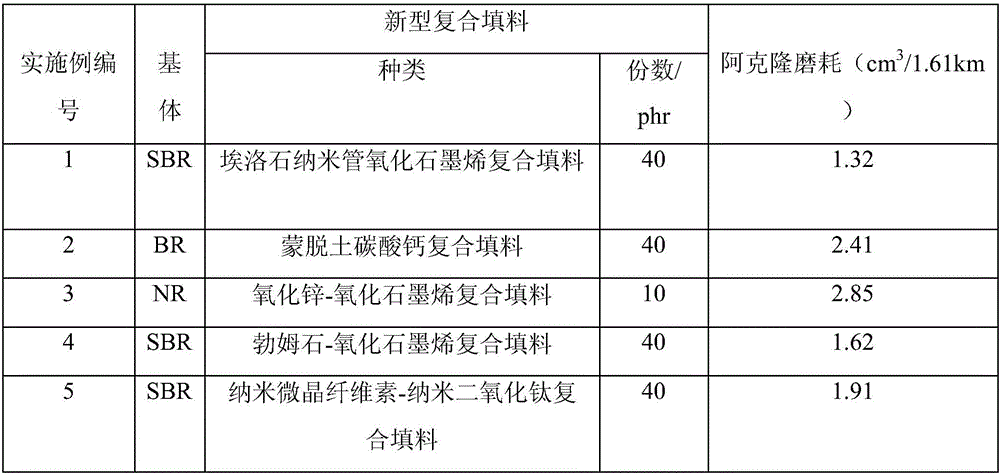

Examples

Embodiment 1

[0023] (1) In a 1L three-neck flask, add 100 g of halloysite nanotubes and 500 mL of 95% ethanol, stir and ultrasonically disperse at room temperature for 30 minutes, so that the halloysite nanotubes are flocculent turbid liquid. Accurately weigh 9.94g (0.04mol) of γ-methacryloxypropyltrimethoxysilane (silane coupling agent KH570) into the halloysite nanotube suspension, raise the temperature to 30°C, add glacial acetic acid to adjust the pH To 6, mechanical stirring at this temperature, reflux reaction for 48 hours, all mechanical stirring speed is 20r / min. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the filter cake was washed with absolute ethanol until the pH value of the washing liquid was 7. The solid product was collected, dried at 80° C. for 48 hours, pulverized, and sieved to obtain halloysite nanotubes modified with γ-methacryloxypropyltrimethoxysilane.

[0024] (2) In a 1L three-neck flask, weigh 1.0g graphene oxid...

Embodiment 2

[0028](1) In a 500mL three-neck flask, add 10g of montmorillonite and disperse it in a mixed solvent composed of 180mL of n-propanol and 20mL of deionized water, stir and ultrasonicate for 30min at room temperature, until the montmorillonite is uniformly dispersed to form a stable suspension, and Add 1.48g (0.01mol) of vinyltrimethoxysilane (silane coupling agent A171) solution dropwise into the montmorillonite suspension, raise the temperature to 80°C, add glacial acetic acid, adjust the pH to 4.5, and mechanically stir (20r / min) , reacted for 24 hours. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the filter cake was washed with absolute ethanol until the pH value of the filtrate was 7. The collected solid product was dried at 90° C. for 36 hours, and ground into powder to obtain a modified montmorillonite whose surface was grafted with vinyltrimethoxysilane.

[0029] (2) In a 500mL three-neck flask, add 10g of untreated nan...

Embodiment 3

[0033] (1) In a 500mL three-neck flask, add 180mL of isopropanol and 20mL of deionized water, then weigh 10g of nano-zinc oxide and add it to the mixed solvent, stir and ultrasonically disperse at room temperature for 30min, and accurately weigh 3.23g (0.02mol) of vinyl triethylene Chlorosilane (silane coupling agent A150) was added to the nano-zinc oxide suspension, the temperature was raised to 60°C, glacial acetic acid was added, the pH was adjusted to 6, mechanically stirred at this temperature, refluxed for 48 hours, all mechanical stirring speed was 200r / min. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the filter cake was washed with absolute ethanol until the pH value of the washing liquid was 7. The collected solid product was dried at 80° C. for 48 hours, pulverized, and sieved to obtain the modified nano-zinc oxide surface-grafted with vinyltrichlorosilane.

[0034] (2) In a 500mL three-neck flask, add 180mL of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com