Collosol of yttrium barium cupper oxygen superconducting film and process for preparing high temp. superconducting film thereof

A technology of high-temperature superconducting thin film and yttrium-barium-copper-oxygen is applied in superconducting/high-conducting conductors, usage of superconducting elements, and superconducting devices. The effect of simple adjustment and preparation process and low fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the sol for the above-mentioned yttrium barium copper oxide high temperature superconducting thin film comprises the following steps:

[0024] 1) Dissolving yttrium acetate in methanol, adding a small amount of diethylenetriamine, making yttrium acetate:methanol:diethylenetriamine=1:(10-40):(1.5-5), forming solution A after stirring;

[0025] 2) Dissolve barium acetate in a mixed solution containing water and trifluoroacetic acid, so that barium acetate: water: trifluoroacetic acid = 1: (10-80): (2-5), after stirring and dissolving, after 65 ° C ~ Dry at 85°C, and dissolve the resulting product in methanol solution so that the molar ratio Ba 2+ : Methanol=1: (10~40), obtain solution B;

[0026] 3) Dissolve copper acetate in methanol, add a small amount of α-methacrylic acid, so that copper acetate: methanol: α-methacrylic acid = 1: (10-40): (2-10), after stirring slightly Solution C is formed;

[0027] 4) Mix the solutions A, B and C obtaine...

Embodiment 1

[0034] Dissolve yttrium acetate in methanol, add diethylenetriamine so that the molar ratio of each component is: yttrium acetate:methanol:diethylenetriamine=1:27:1.5, and form solution A after stirring and clarification.

[0035]Dissolve barium acetate in a mixed liquid containing water and trifluoroacetic acid so that barium acetate: water: trifluoroacetic acid = 1:40:3. After stirring and dissolving, the substance obtained after drying at 80°C was redissolved in methanol solution so that the molar ratio Ba 2+ :methanol=1:20, and solution B was obtained after stirring and clarification.

[0036] Dissolve copper acetate in methanol, add a small amount of α-methacrylic acid to make copper acetate:methanol:α-methacrylic acid=1:22:2, and form solution C after slight heating and stirring.

[0037] Mix the above solutions A, B, and C, and stir, so that Y 3 +: Ba 2+ : Cu 2+ =1:2:3.2, forming the required sol.

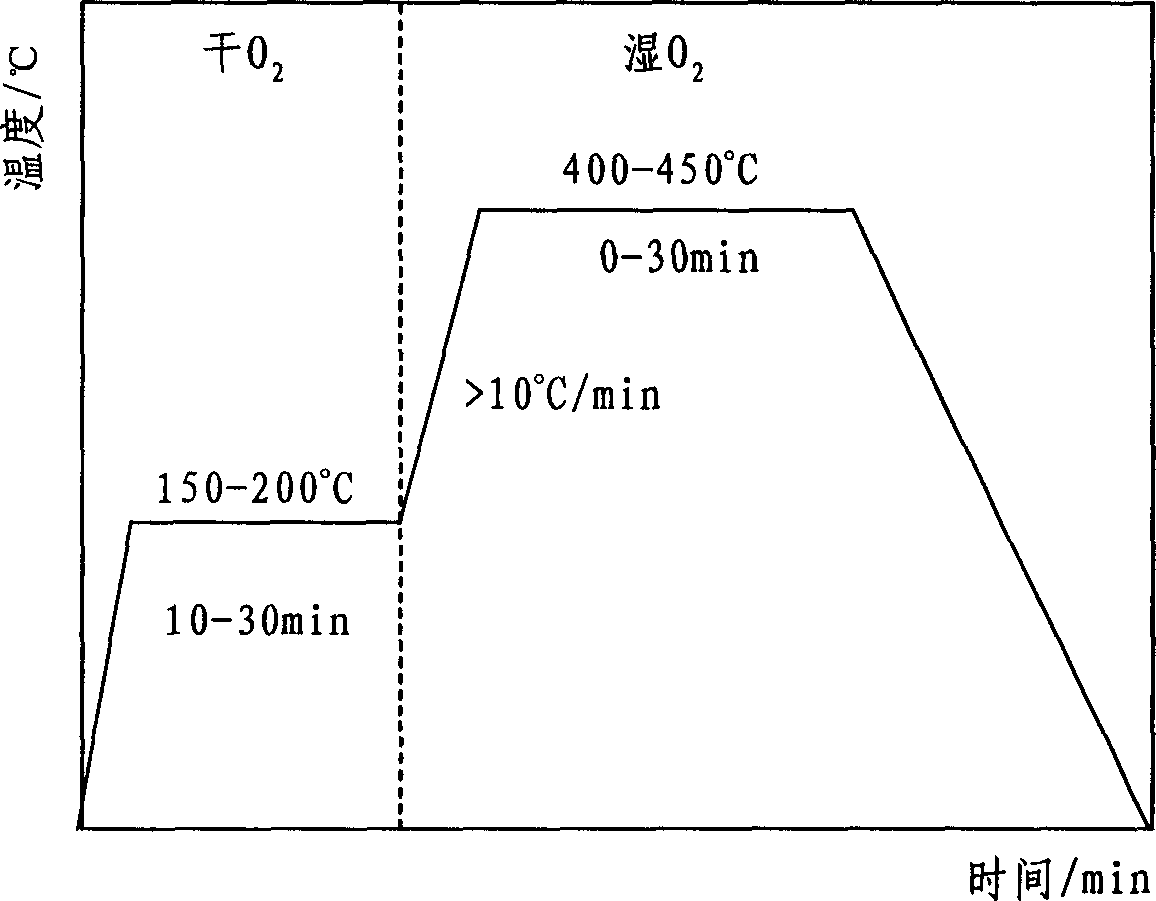

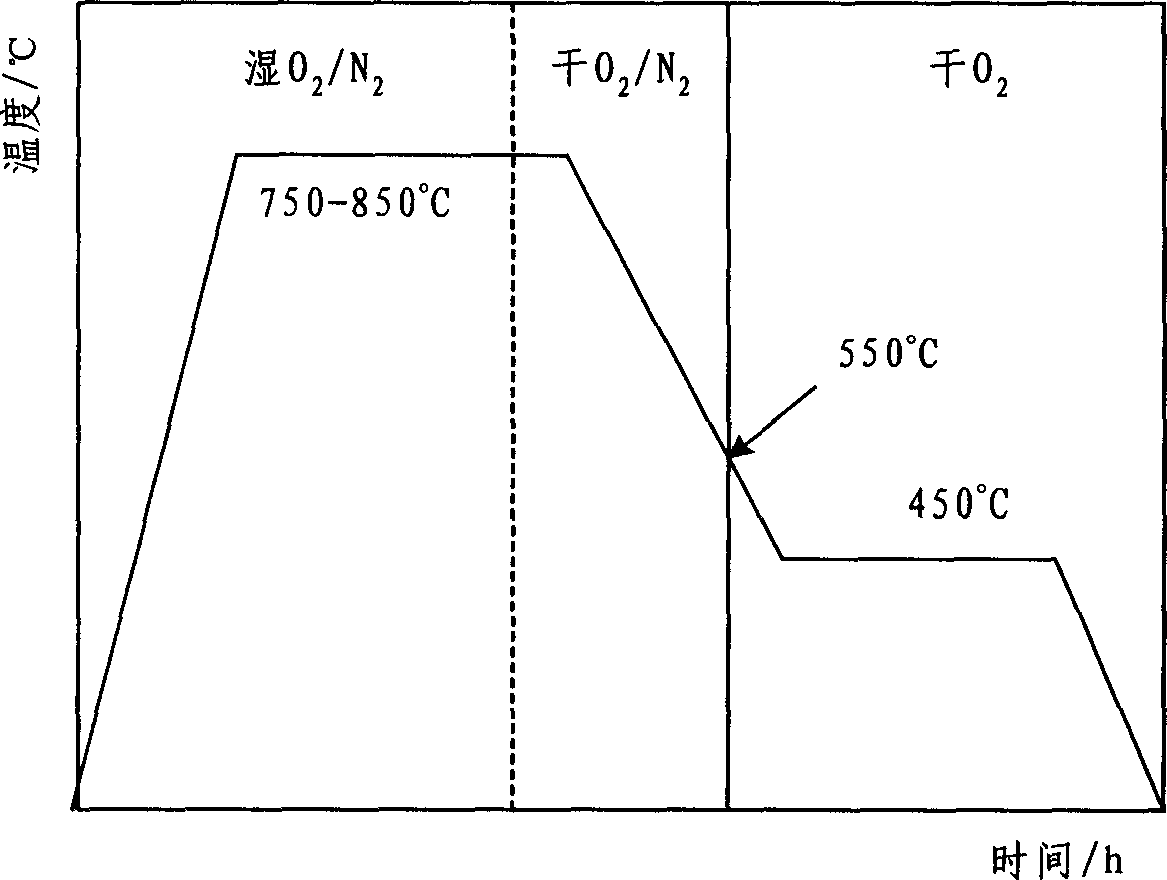

[0038] Using the sol, a layer of gel film was coated on the single...

Embodiment 2

[0040] Dissolve yttrium acetate in methanol, add diethylenetriamine so that the molar ratio of each component is: yttrium acetate:methanol:diethylenetriamine=1:25:1.5, and form solution A after stirring and clarification.

[0041] Dissolve barium acetate in a mixed solution of water and trifluoroacetic acid so that barium acetate: water: trifluoroacetic acid = 1:40:3, stir and dissolve, and dry at 75°C to form a viscous glassy substance. and redissolved in methanol solution such that the molar ratio Ba 2+ :methanol=1:16, and solution B was obtained after stirring and clarification.

[0042] Take copper acetate as the raw material, dissolve it in methanol, add a small amount of propionic acid to make copper acetate: methanol: propionic acid = 1:25:3, and form solution C after slight heating and stirring.

[0043] Mix the above three solutions A, B, and C and stir, so that Y 3+ : Ba 2+ : Cu 2+ =1:2:4, forming the required sol. The above-mentioned copper acetate can be repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com