Process for producing wafer

A manufacturing method and wafer technology are applied in the manufacture of epitaxial wafers, which can manufacture wafers at low cost and anneal the wafers, and can solve problems such as surface roughness, corrosion treatment equipment, and long time, so as to shorten the heat treatment process. effect of time, increased productivity, and reduced metal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

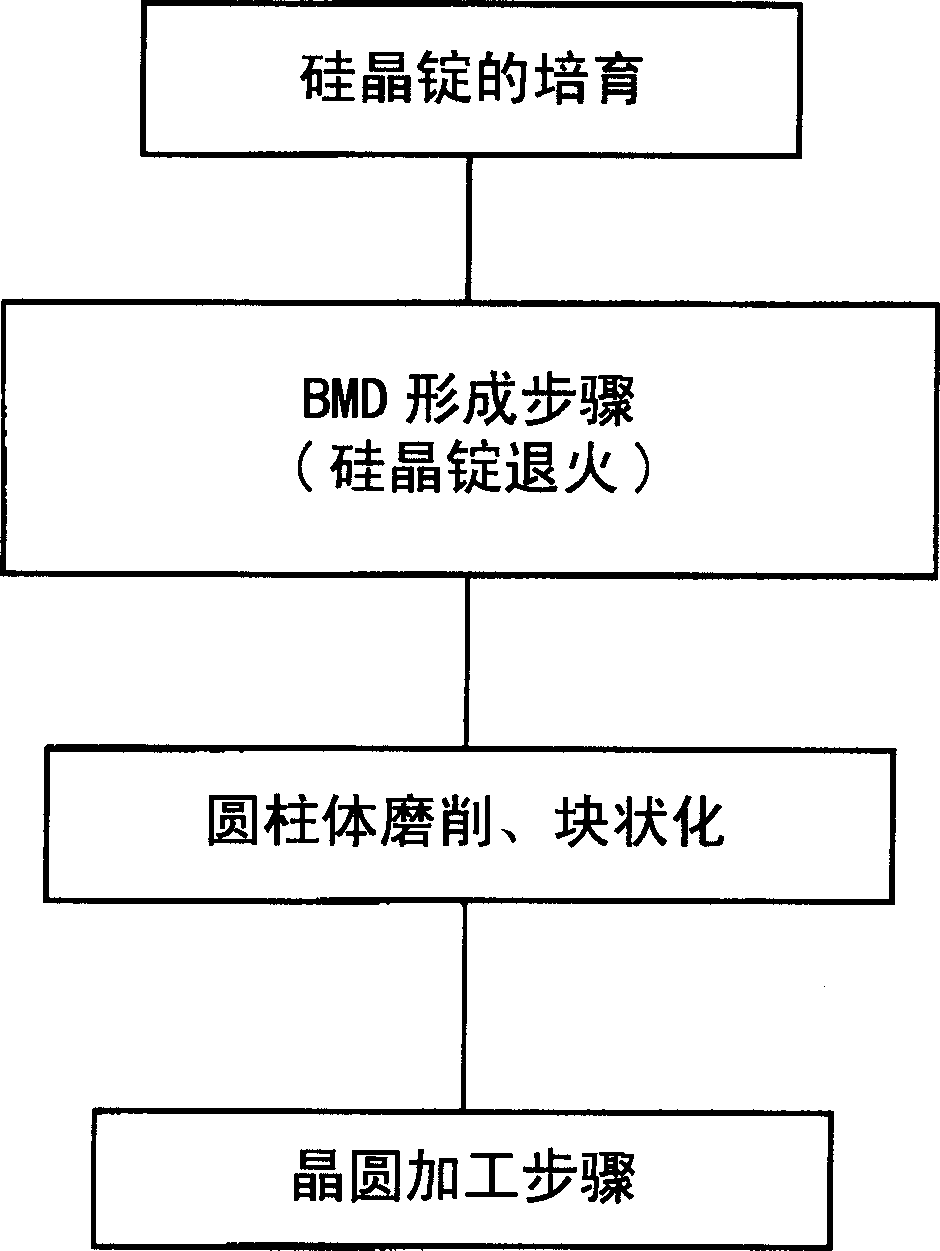

[0167] (Cultivation of silicon ingots)

[0168] By CZ method, the growth oxygen concentration is 13~15×10 17 atoms / cm 3 [oldASTM], the nitrogen concentration is 5~9×10 12 atoms / cm 3 silicon monocrystalline silicon ingot. The silicon ingot is cylindrically ground and cut into a plurality of silicon ingots to obtain a silicon ingot with a diameter of about 300 mm and a length of about 30 cm.

[0169] (Silicon ingot annealing: BMD formation step)

[0170] The above-mentioned silicon crystal ingot is heat-treated as it is in the state of the silicon crystal ingot, and a BMD forming step of forming a BMD inside is performed. First, use the HF / HNO 3 The formed acidic etchant performs about 200 micron etching to remove metal impurities that contaminate the surface.

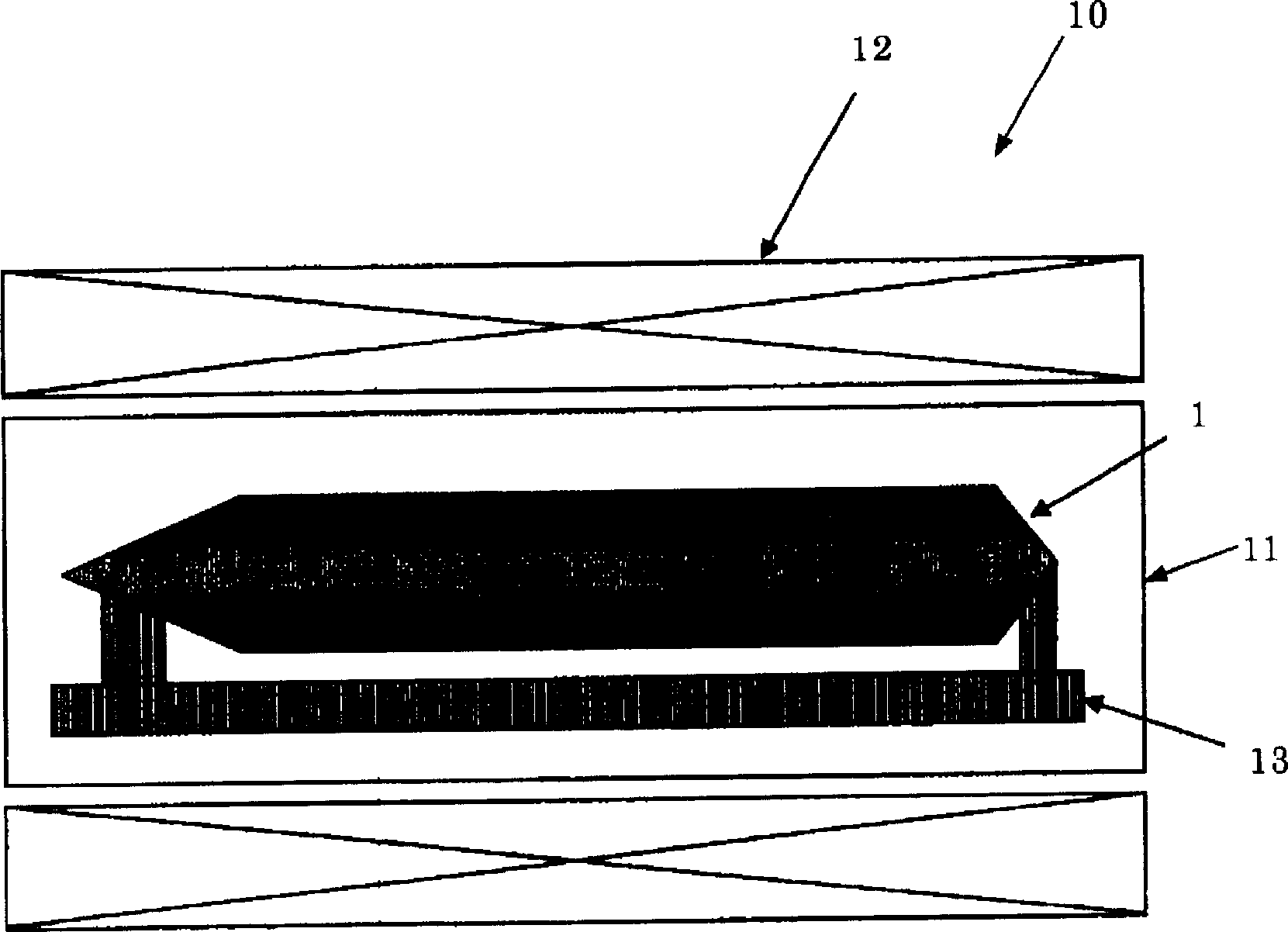

[0171] Next, in the state of the crystalline silicon ingot as it is, put Figure 4 Heat treatment is performed in the heat treatment furnace shown.

[0172] The heat treatment was carried out from room temperatu...

Embodiment 2

[0178] (Cultivation of silicon ingots)

[0179] By CZ method, the growth oxygen concentration is 13~15×10 17 atoms / cm 3 [oldASTM] silicon monocrystalline silicon ingot. This silicon single crystal is a crystal in which the NPC region is grown by controlling the crystal growth rate. By cutting the silicon crystal ingot into a plurality of silicon crystal blocks, a silicon crystal ingot with a diameter of about 300 mm and a length of about 30 cm was obtained.

[0180] Subsequently, in the same manner as in Example 1, the BMD formation step and wafer processing were performed to obtain about 300 silicon wafers with a diameter of 300 mm. As a result of evaluating the BMD density of the wafer thus obtained using infrared photography, it was 3×10 9 piece / cm 3 , with sufficient BMD density, wafers with high IG capability can be obtained.

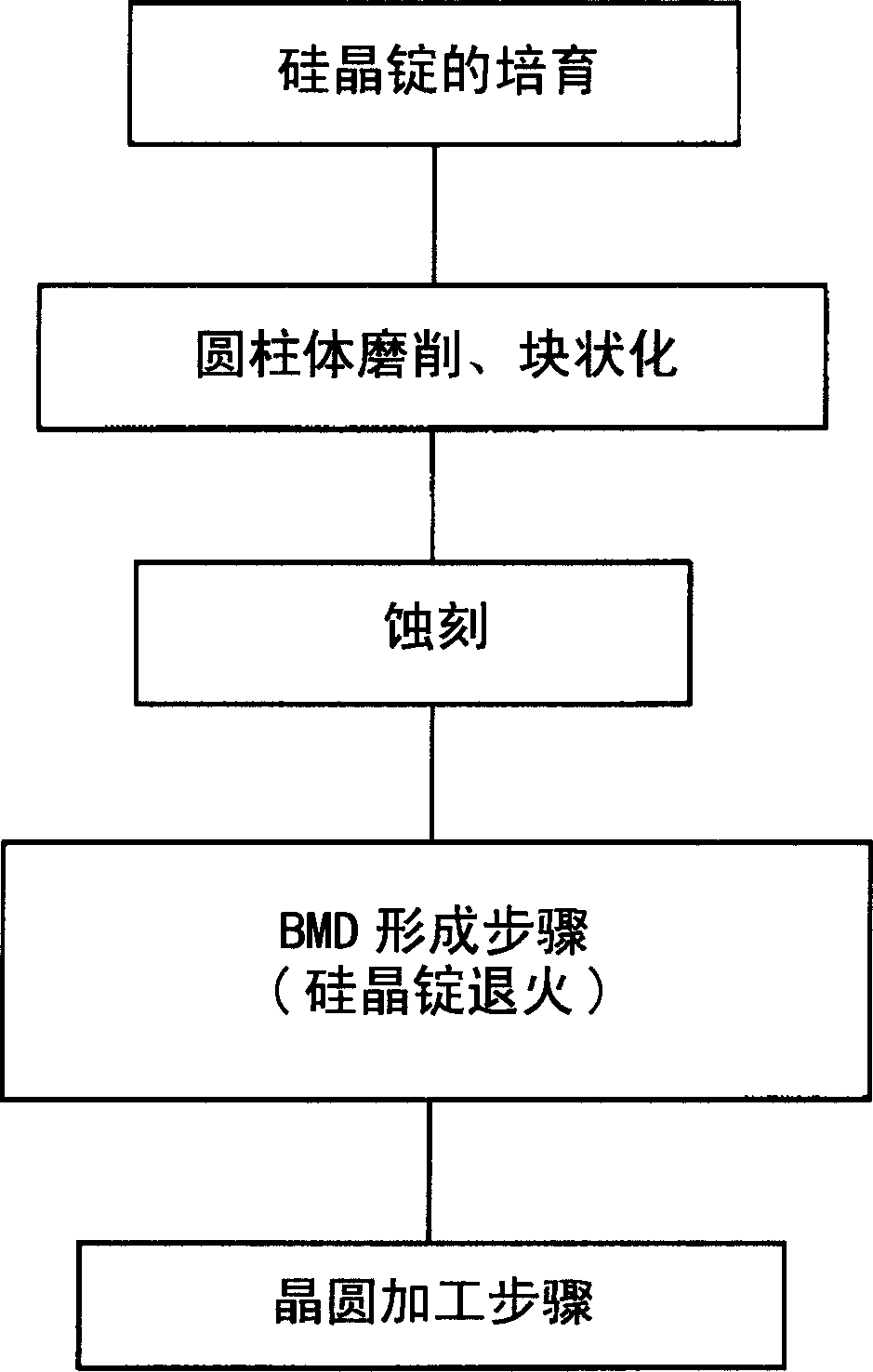

Embodiment 3

[0185] (Cultivation of silicon ingots)

[0186] By CZ method, the growth oxygen concentration is 13~15×10 17 atoms / cm 3 [oldASTM], the nitrogen concentration is 5~9×10 12 atoms / cm 3 silicon monocrystalline silicon ingot. The silicon ingot is cylindrically ground and cut into a plurality of silicon ingots to obtain a silicon ingot with a diameter of about 300 mm and a length of about 30 cm.

[0187] (Silicon ingot annealing: first heat treatment step)

[0188] To above-mentioned silicon crystal ingot, carry out the first heat treatment with the state of silicon crystal ingot as it is, at first, use by HF / HNO 3 The formed acidic etchant performs about 200 micron etching to remove metal impurities that contaminate the surface.

[0189] Next, in the state of the crystalline silicon ingot as it is, put Figure 4 Heat treatment is performed in the heat treatment furnace shown.

[0190] The heat treatment was carried out from room temperature to 500°C at a heating rate of 10°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com