Preparation method of cobalt sulfide micro tube with hiberarchy structure

A technology of hierarchical structures and microtubes, which is applied in separation methods, microstructure devices without moving elements, chemical instruments and methods, etc., can solve the problem of microtubes that cannot be synthesized with hierarchical cobalt sulfide, irregular cobalt sulfide morphology, Synthetic method is complicated to operate and other problems, and achieves the effect of excellent electrical and magnetic properties, simple equipment, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

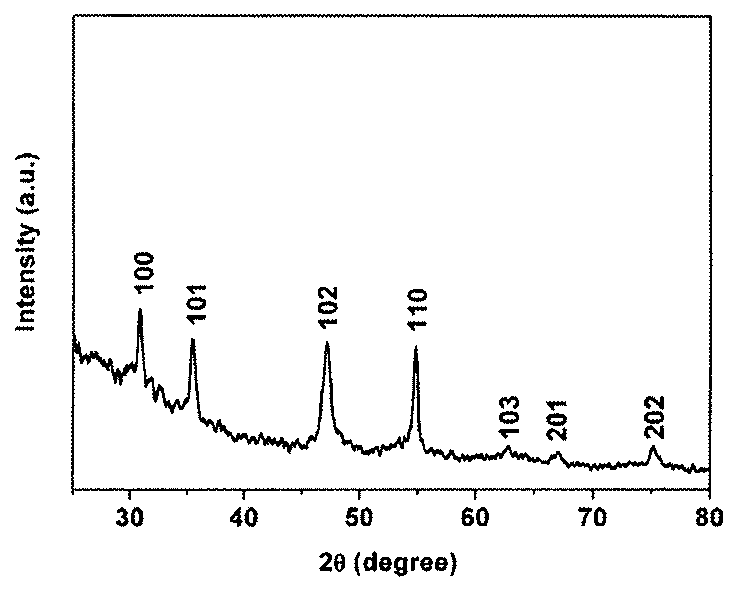

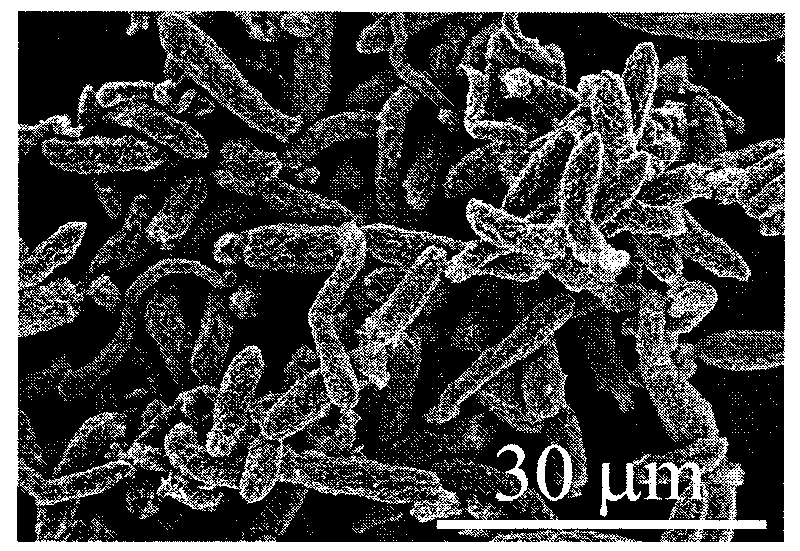

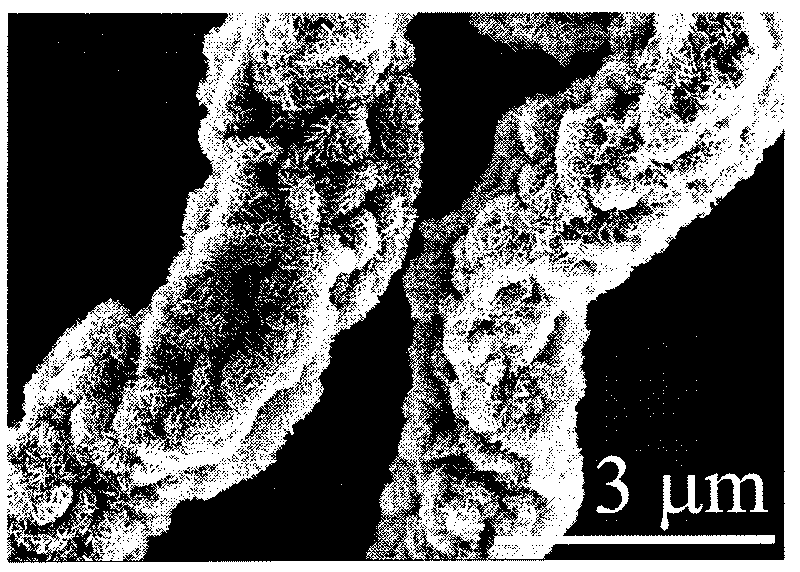

[0016] First, fully mix 4 ml of deionized water with 4 ml of ethylenediamine, weigh 0.0001 mole of cobalt acetate, add it to the above solution under stirring, and continue stirring the mixed solution for 5 minutes; Ammonium bromide CTAB was added to the above solution, slightly heated to dissolve it; then 0.0003 moles of thioacetamide was added to the above mixture, stirred for 15 minutes and then loaded into a stainless steel reactor with a Teflon liner , sealed the reactor, and reacted at 160°C for 24 hours. Then cool to room temperature, open the reactor, filter with Buchner funnel, wash with deionized water and absolute ethanol to obtain a black powder. The product was identified as hexagonal cobalt sulfide (Co 1-x S) (X=0.75) (attached figure 1 ), the black powder was identified as a micron tube by a low-magnification scanning electron microscope, and the average length of the tube was about 15 microns (attached figure 2 ). High-magnification scanning electron micro...

Embodiment 2

[0018] First, fully mix 4 milliliters of deionized water with 4 milliliters of ethylenediamine, weigh 0.0001 moles of cobalt nitrate, add it to the above solution under stirring conditions, and continue to stir the mixed solution for 5 minutes; Ammonium bromide CTAB was added to the above solution, slightly heated to dissolve it; then 0.0003 moles of thioacetamide was added to the above mixture, stirred for 15 minutes and then loaded into a stainless steel reactor with a Teflon liner , sealed the reactor, and reacted at 160°C for 24 hours. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water and absolute ethanol to obtain cobalt sulfide microtubes with the same length as in Example 1.

Embodiment 3

[0020] First, fully mix 4 milliliters of deionized water with 4 milliliters of ethylenediamine, weigh 0.0001 moles of cobalt chloride, add it to the above solution under stirring conditions, and continue to stir the mixed solution for 5 minutes; Add methyl ammonium bromide CTAB to the above solution, heat it slightly to dissolve it; then add 0.0003 moles of thioacetamide to the above mixture, stir for 15 minutes and then put it into a stainless steel with Teflon lining for reaction In the kettle, seal the reaction kettle, and react at 160° C. for 24 hours. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water and absolute ethanol to obtain cobalt sulfide microtubes with the same length as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com