Megawatt level composite material wind electricity blade vacuum guiding and forming technique

A technology of vacuum introduction molding and composite materials, applied in the direction of sustainable manufacturing/processing, household components, applications, etc., can solve the problems of poor quality stability, low efficiency, high cost, etc., and achieve high product performance, good quality stability, and harmful The effect of less volatilization of inert gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

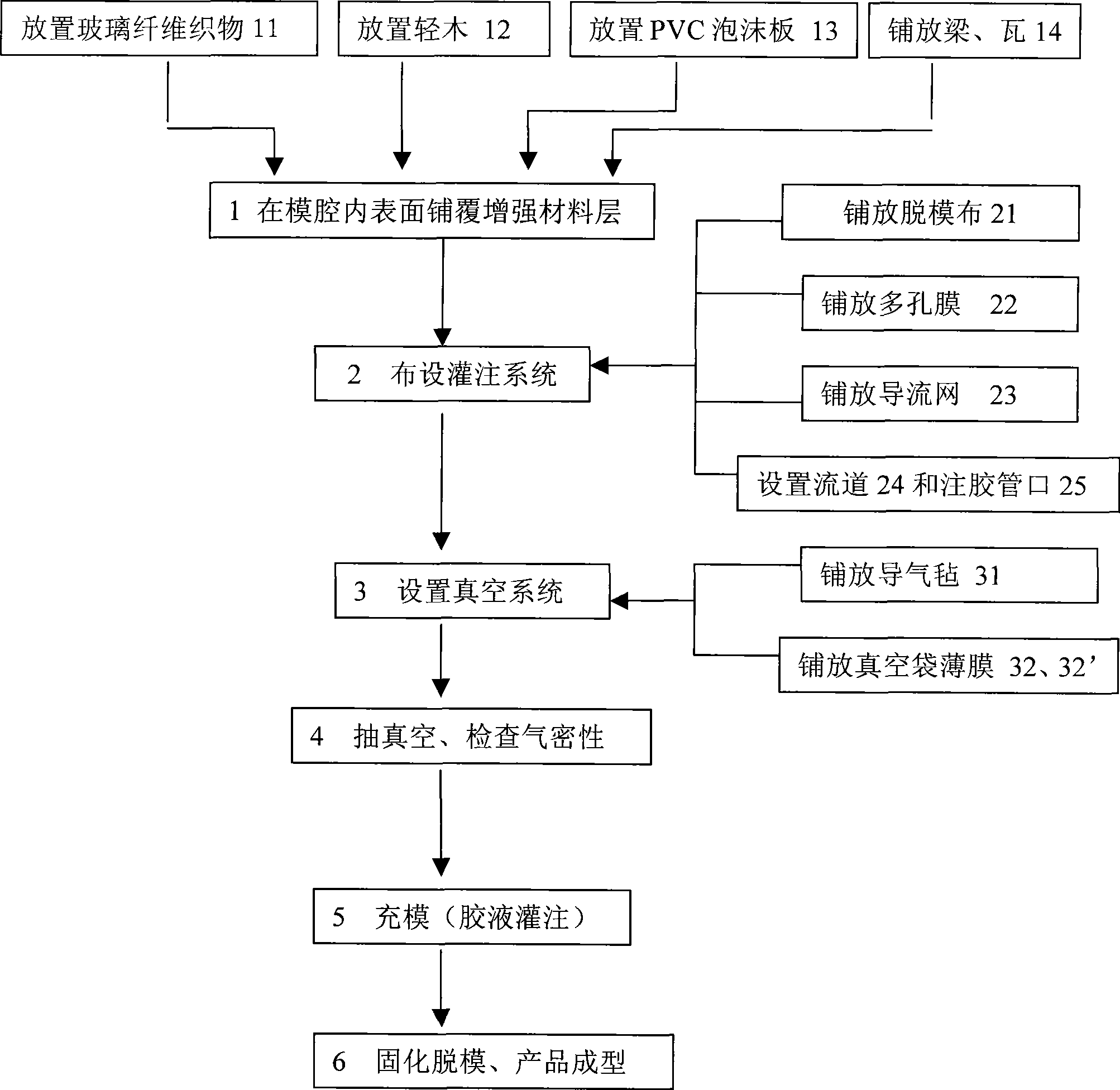

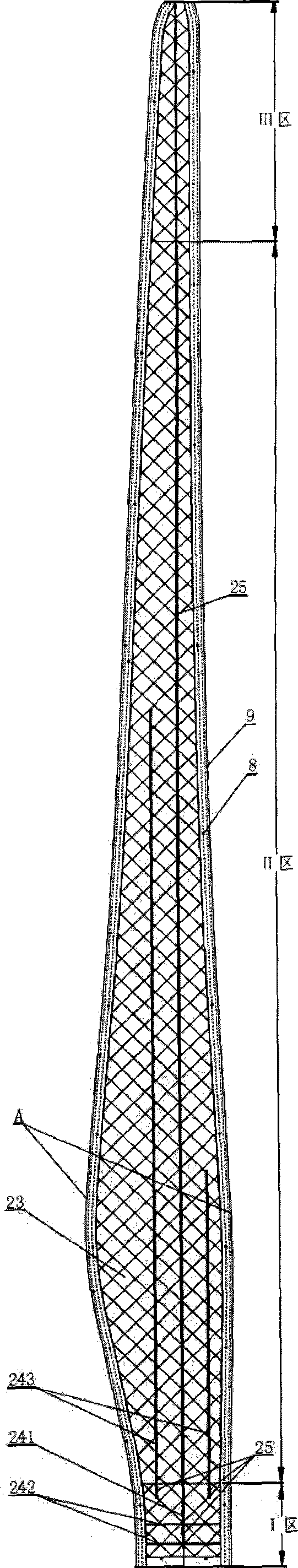

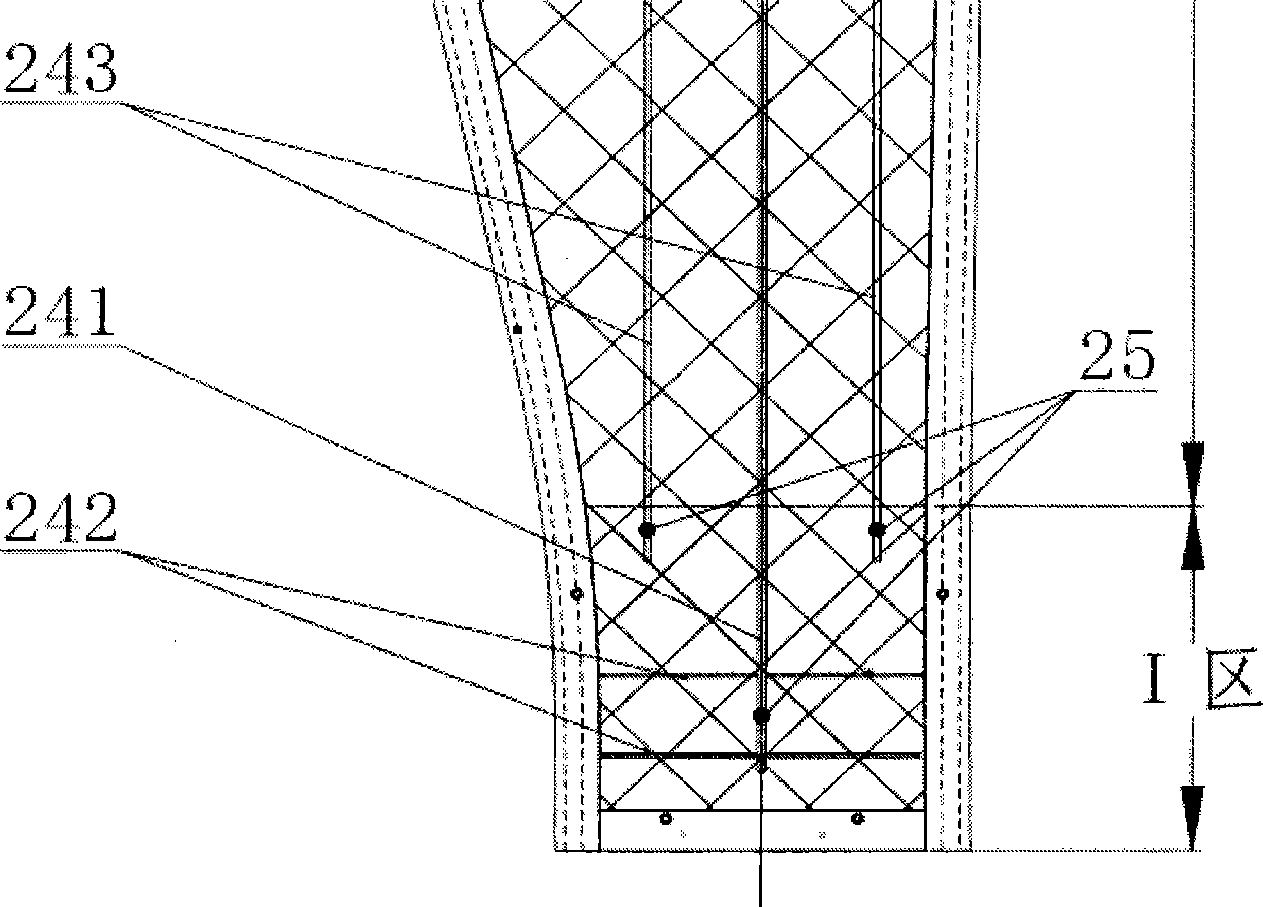

[0031] Such as figure 1 , figure 2As shown, the vacuum introduction molding process of the present invention is realized by a wind power blade mold including zone I of blade root, zone II of blade middle and zone III of blade tip, wherein zone I of blade root refers to 0 to 7% of the longitudinal length of the mold Zone II in the middle of the leaf refers to 7% to 85% of the longitudinal length of the mold, and then zone III of the tip. The mold is composed of an upper mold and a lower mold. The opposite surface of the upper mold and the lower mold is the parting surface A of the mould. The main molding process is as follows:

[0032] 1) pave the reinforcing material layer in the mold cavity respectively;

[0033] 2) Layout perfusion system;

[0034] 3) Set the vacuum system;

[0035] 4) Vacuumize and check the airtightness;

[0036] 5) mold filling, (glue filling);

[0037] 6) Curing and demoulding, product molding.

[0038] Wherein, the mold cavity in step 1) refers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com