Method for connecting TiNi shape memory alloy and austenitic stainless steel heterogenetic material

A technology of austenitic stainless steel and memory alloy, which is applied in the fields of machinery, medical treatment, materials, and electricity to achieve automatic welding, good plasticity, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

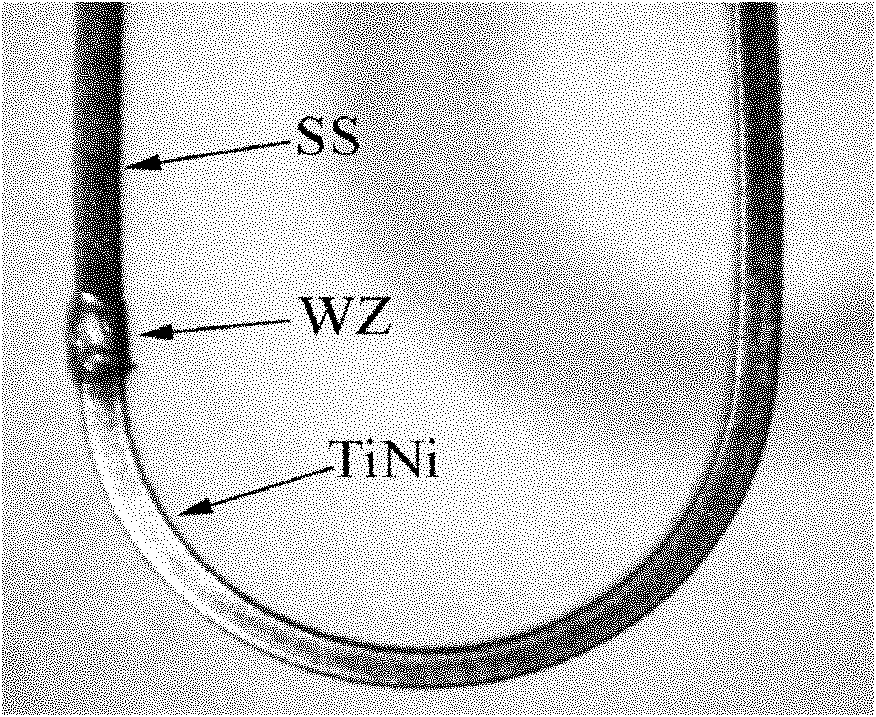

Embodiment 1

[0019] Embodiment 1. Using the method of the present invention to carry out laser welding of TiNi alloy wire and stainless steel wire to prepare dental compound orthodontic arch wire. The cross-sectional dimensions of TiNi alloy wire and stainless steel wire are both 0.64mm (width)×0.48mm (thickness). A copper intermediate layer (thickness 80 μm) was placed on the interface between TiNi alloy wire and stainless steel wire (without leaving a gap), and a pulsed laser heat source was used to melt the interface area to form a welded joint of TiNi alloy-stainless steel dissimilar materials. Laser welding process parameters: pulse energy 7.2J; pulse width 6ms; shielding gas (Ar) flow rate 8L / min. The tensile strength of TiNi alloy-stainless steel dissimilar material laser welding joint is 520MPa (compared with the joint without copper interlayer, the joint strength is increased by more than 2 times); the bending angle of the laser welding joint is 180° (compared with the joint witho...

Embodiment 2

[0020] Embodiment 2, adopt the method of the present invention to carry out the laser welding of TiNi alloy and stainless steel plate. The thickness of both the TiNi alloy and the stainless steel is 0.54 mm. The copper interlayer (thickness 90 μm) is placed on the TiNi alloy and stainless steel interface (without leaving a gap), and the interface area is melted by a pulsed laser heat source to form a TiNi alloy-stainless steel welded joint. Laser welding process parameters: pulse frequency 30Hz; pulse width 5ms; laser power 312W; welding speed 1m / min; shielding gas (Ar) flow rate 9L / min. The tensile strength of the TiNi alloy-stainless steel laser welded joint is 510MPa; the bending angle of the joint is >120°; the shape memory effect recovery rate of the TiNi alloy heat-affected zone of the joint is >90%.

Embodiment 3

[0021] Embodiment 3, adopt the method of the present invention to carry out micro-beam plasma arc welding of TiNi alloy and stainless steel plate. The thickness of the TiNi alloy and stainless steel plates is 0.75 mm. The copper intermediate layer (thickness 120 μm) is placed on the TiNi alloy and stainless steel interface (without leaving a gap), and the micro-beam plasma arc heat source is used to heat and melt the interface area to form a TiNi alloy-stainless steel welded joint. Micro-beam plasma arc welding process parameters: welding current 10A; welding speed 12.5cm / min; ion gas (Ar) flow rate 0.28L / min; shielding gas (H21%+Ar) flow rate 9.5L / min; nozzle aperture 0.75mm. The tensile strength of the TiNi alloy-stainless steel micro-beam plasma arc welding joint is 500 MPa; the bending angle of the joint is >80°; the shape memory effect recovery rate of the TiNi alloy heat-affected zone of the welded joint is >85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com