Microcapsule preparation method

A technology of microcapsules and capsule cores, which is applied in the field of microcapsule preparation, can solve the problems of high heat consumption, large medium consumption, and low thermal efficiency of equipment, and achieve the effects of easy amplification, simple operation process, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

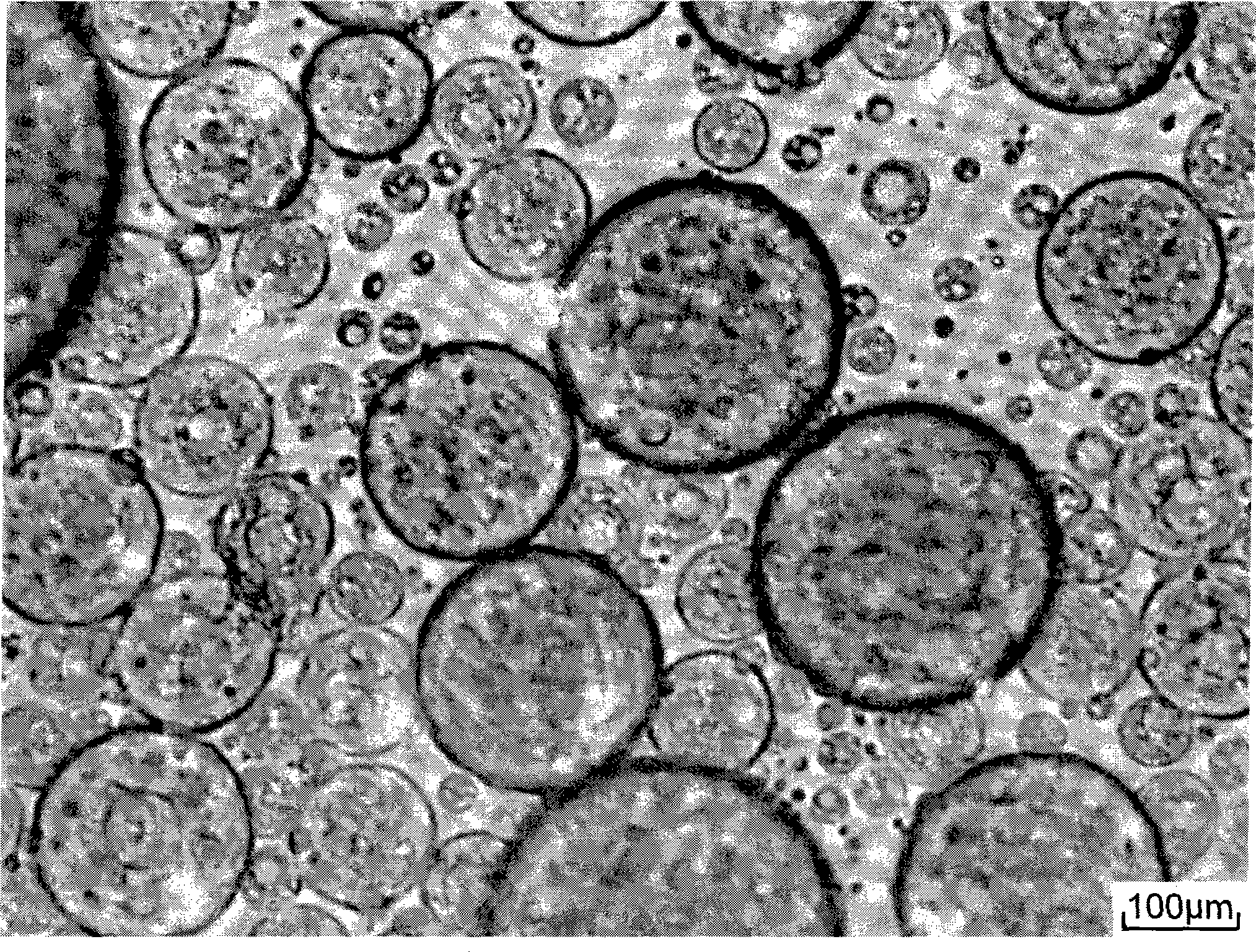

Image

Examples

Embodiment 1

[0032] Weigh 1.2 g of ethyl cellulose and dissolve it in 40 ml of chloroform, weigh 0.6 g of diclofenac sodium and dissolve it in 5 ml of methanol, and mix the two to make a mixed solution. Then it was added into 90 ml of distilled water dissolved with 0.18 g of sodium lauryl sulfate, and a stable emulsion was obtained by electromagnetic stirring at 800 r / min. At this time, due to the transfer of part of methanol to water, diclofenac sodium phase-separated and was dispersed in the inner phase of the emulsion in the form of solid particles. Then transfer the emulsion to a rotary evaporator to evaporate under reduced pressure to remove volatile chloroform and part of methanol until the wall material is precipitated to obtain microcapsules. Then carry out suction filtration, wash with deionized water, and vacuum-dry to obtain ethyl cellulose microcapsules encapsulating diclofenac sodium.

[0033] Gained microcapsules are dissolved in dehydrated alcohol, filter with filter paper ...

Embodiment 2

[0035] Weigh 0.4g of ethyl cellulose and dissolve it in 40ml of chloroform, weigh 0.4g of acetaminophen and dissolve it in 5ml of methanol, and mix the two to make a mixed solution. It was then added to 45 ml of distilled water dissolved with 0.0135 g of sodium lauryl sulfate, and a stable emulsion was obtained by electromagnetic stirring. The particulate form is dispersed in the inner phase of the emulsion. Then transfer to a rotary evaporator to evaporate under reduced pressure to remove volatile chloroform and part of methanol until the wall material is precipitated to obtain microcapsules. Then carry out suction filtration, wash with deionized water, and vacuum-dry to obtain ethyl cellulose microcapsules encapsulating acetaminophen.

[0036] Gained microcapsules are dissolved in dehydrated alcohol, filter with filter paper after sonication, record its absorbance value at 208nmnm place with ultraviolet spectrophotometry, compare the standard curve of absorbance and concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com