Preparation method of ultrathin continuous fiber reinforced thermoplastic prepreg

A technology for enhancing thermoplasticity and continuous fibers, applied in the direction of coating, etc., can solve problems such as the difficulty of the molten resin matrix penetrating into the interior of continuous fiber bundles, and achieve good fiber opening effect and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

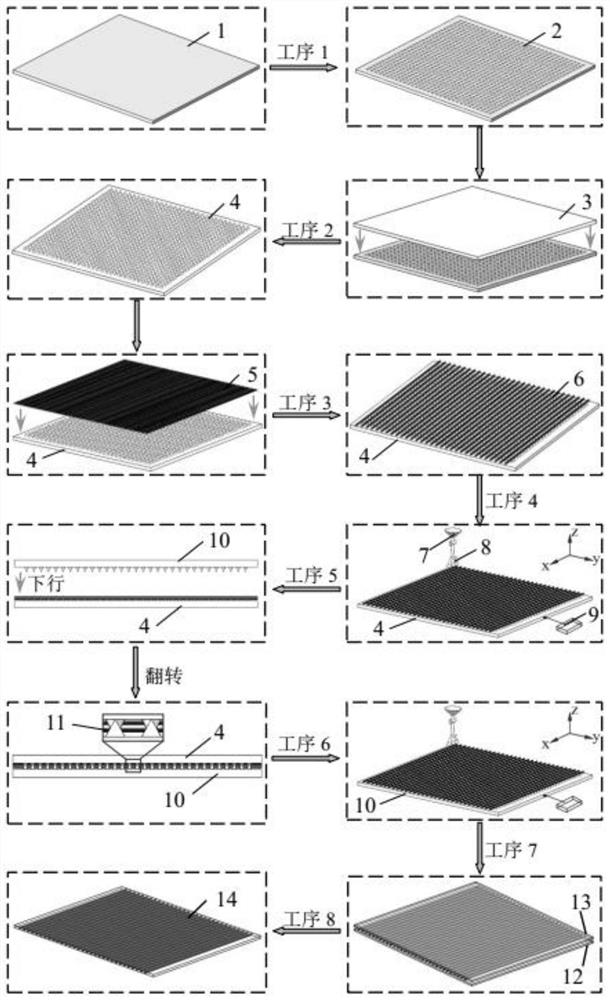

[0022] Such as figure 1 Shown, a kind of preparation method of ultra-thin continuous fiber reinforced thermoplastic prepreg of the present invention specifically comprises the following steps:

[0023] Step (1), using laser drilling, by controlling the laser frequency 20KHz, laser power 16W, spot diameter Parameters such as the number of impacts 20 times, on the surface of 1050-H14 aluminum sheet 1 with a length and width of 100mm×100mm and a thickness of 1mm, an array of tapered holes with 30 rows×30 columns, a diameter of 0.8mm, and a depth of 1mm is processed. A metal mold 2 with a micro-taper hole array feature is taken, wherein the diameter, number of rows, and number of columns of the array of tapered holes are determined by the degree of fiber opening, and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com