A kind of preparation method of velvet fabric blank, velvet fabric and velvet fabric

A fabric and velvet-feeling technology, applied in the velvet-feeling fabric and its preparation, and in the field of nylon long velvet-feeling fabric blanks, can solve the problems of low strength of velvet-feeling fabrics and weak velvet feel, and achieve good velvet feel, good hand feeling, The effect of strong transmission and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

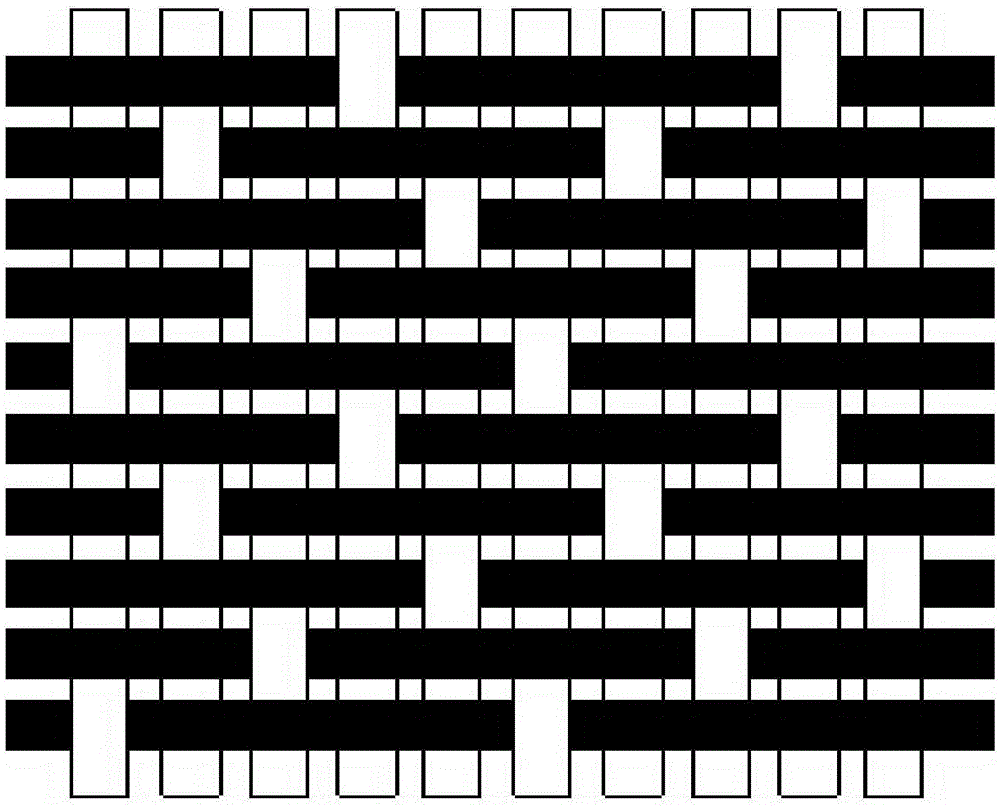

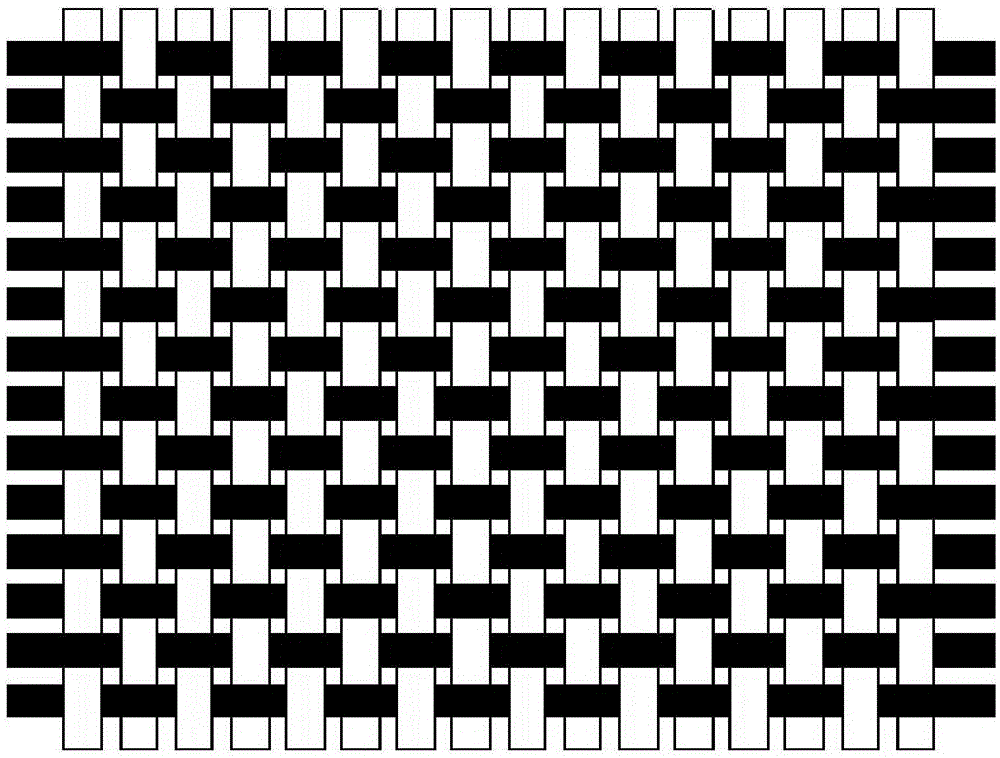

Image

Examples

Embodiment 1

[0028]The warp yarn is 40D / 34F nylon yarn, and the weft yarn is composite yarn of modified high-shrinkage nylon and ordinary polyester. The mass ratio of nylon and polyester is 7:3, and the composite yarn is 50D / 24F. The weave is 3 / 1 twill weave on an air jet loom. The woven fabric blank adopts the following post-processing technology:

[0029] 1. Desizing: Put the aforementioned woven fabric blank into the dyeing vat for desizing treatment. The components of the desizing finishing solution are: 30% caustic soda 14.5g / L, degreasing agent 1.5g / L, chelating Dispersant 0.5g / L. The following desizing process is adopted: add water according to the bath ratio of 1:10, raise the temperature of the water to 40°C, add the desizing finishing solution, and circulate the water for 5 to 10 minutes, and raise the temperature to 1.5°C / min. 100°C and then keep warm for 85 minutes, then cool down to 65°C at a rate of 1.5°C / min, then overflow and cool down to 40°C, and drain the water out of ...

Embodiment 2

[0033] Each parameter is shown in Table 1, and all the other are with embodiment 1.

Embodiment 3-5

[0035] Each parameter is shown in Table 1, and all the other are with embodiment 1.

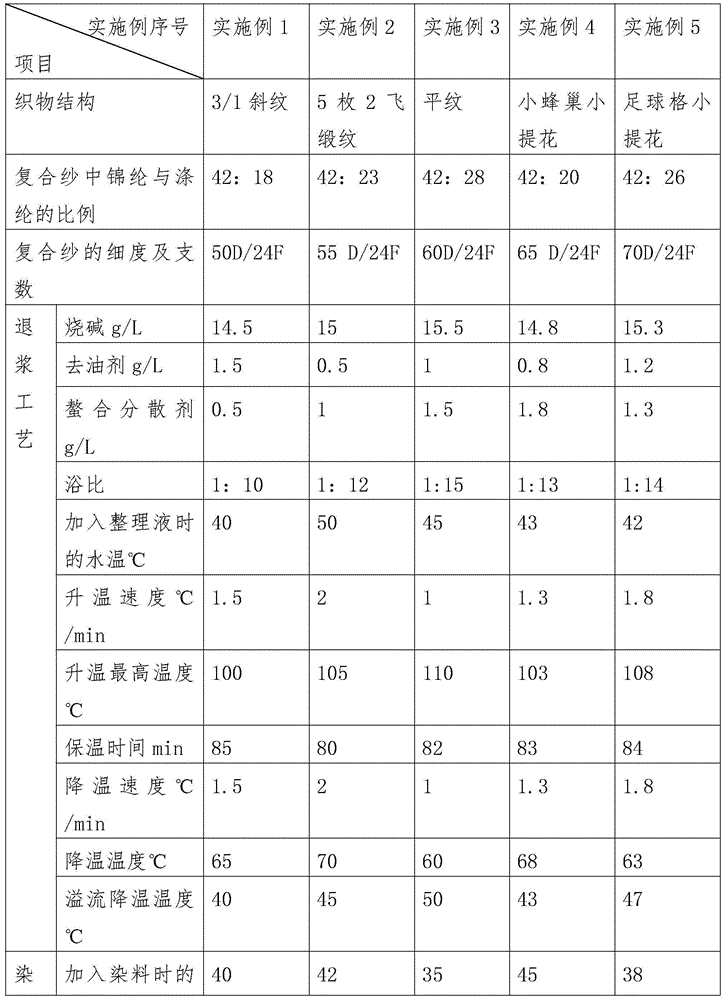

[0036] Table 1: Parameters and performance indicators of cashmere fabric examples

[0037]

[0038]

[0039] Table 2: The performance index table of the cashmere fabric prepared by conventional methods such as fiber opening, napping, napping, and cutting pile:

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com