Dyeing and finishing process of high-shrinkage and easy-to-dye polyester-nylon composite yarn fabric

A composite yarn, dyeing and finishing technology, applied in the field of textile dyeing and finishing, can solve the problems of low color fastness, poor dyeing property, and affecting product quality, etc., achieve natural velvet feeling, best wool effect, and increase saturation and vividness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

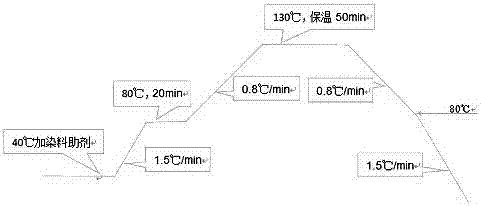

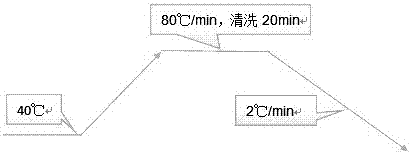

Method used

Image

Examples

Embodiment 1

[0035] The dyeing and finishing process of the high-shrinkage and easy-to-dye polyester-nylon composite silk fabric of the present invention is carried out according to the following process: reducing the weight of the cloth → opening → pre-setting → overflow dyeing → dehydration and drying → finalizing, wherein the reduction of the cloth is first. The gray cloth is subjected to cold-stack reduction treatment, and then enters the open-width refining reduction step, and the process conditions of the cold-stack reduction step are as follows:

[0036] Liquid caustic soda 110 g / L

[0037] Alkali rate 8%

[0038] Speed 18r / min

[0039] time 24 h;

[0040] The technological condition of described open-width scouring reduction step:

[0041] NaOH concentration 15g / L

[0042] Accelerator MK concentration 2g / L

[0043] Liquid alkali concentration 45g / L

[0044] Bath ratio 1:20

[0045] Refining speed 40 m / min;

[0046] The open-width scouring reduction is carried out accordin...

Embodiment 2

[0057] The dyeing and finishing process of the high-shrinkage and easy-to-dye polyester-nylon composite silk fabric of the present invention is carried out according to the following process: reducing the weight of the cloth → opening → pre-setting → overflow dyeing → dehydration and drying → finalizing, wherein the reduction of the cloth is first. The gray cloth is subjected to cold-stack reduction treatment, and then enters the open-width refining reduction step, and the process conditions of the cold-stack reduction step are as follows:

[0058] Liquid caustic soda 135 g / L

[0059] Alkali rate 9%

[0060] Speed 17r / min

[0061] time 24 h;

[0062] The technological condition of described open-width scouring reduction step:

[0063] NaOH concentration 15g / L

[0064] Accelerator MK concentration 2g / L

[0065] Liquid alkali concentration 45g / L

[0066] Bath ratio 1:20

[0067] Refining speed 40 m / min;

[0068] The open-width scouring reduction is carried out according ...

Embodiment 3

[0079] The dyeing and finishing process of the high-shrinkage and easy-to-dye polyester-nylon composite silk fabric of the present invention is carried out according to the following process: reducing the weight of the cloth → opening → pre-setting → overflow dyeing → dehydration and drying → finalizing, wherein the reduction of the cloth is first. The gray cloth is subjected to cold-stack reduction treatment, and then enters the open-width refining reduction step, and the process conditions of the cold-stack reduction step are as follows:

[0080] Liquid caustic soda 150 g / L

[0081] Alkali rate 8.5%

[0082] Speed 17r / min

[0083] time 24 h;

[0084] The technological condition of described open-width scouring reduction step:

[0085] NaOH concentration 15g / L

[0086] Accelerator MK concentration 2g / L

[0087] Liquid alkali concentration 45g / L

[0088] Bath ratio 1:20;

[0089] Refining speed 40 m / min

[0090] The open-width scouring reduction is carried out accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com