Reinforcing short fiber for cement molding

A technology for forming bodies and short fibers, applied in the directions of fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the problems of unable to obtain reinforced short fibers, insufficient fiber opening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

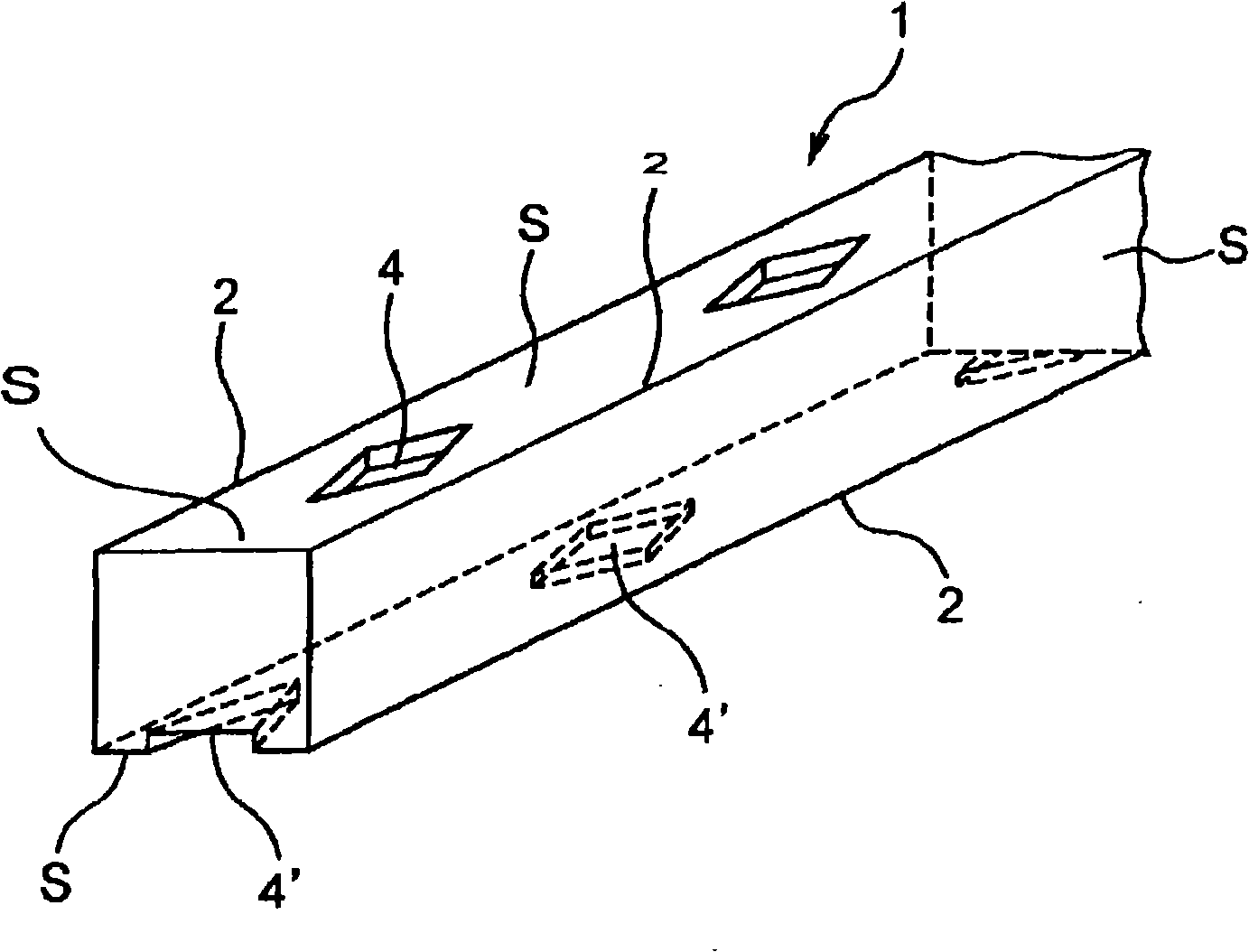

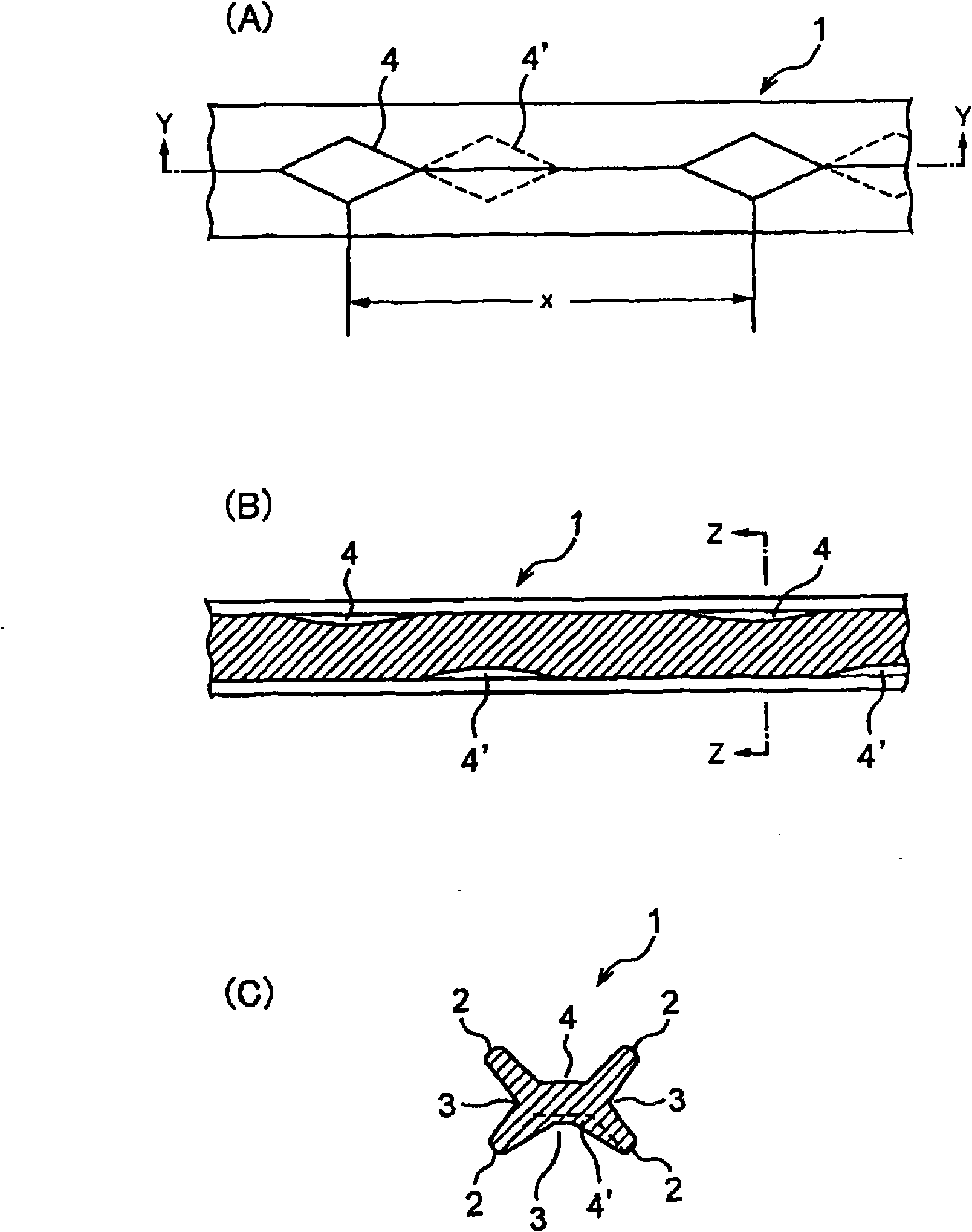

[0086] Using a single-axis melt extruder equipped with a nozzle with 16 holes and an X-shaped hole, the isotactic polypropylene resin (WF464N, manufactured by Sumitomo Chemical) with MFR = 2g / 10 minutes was extruded at a temperature of 255°C In melt extrusion, the extruded resin is put into a cooling water tank, and while it is solidified, it is drawn out at a constant speed with 5 parallel stretching rolls. The drawn fiber strands were directly and continuously put into a 95°C hot water heating drawing tank, and stretched 6.9 times by the second drawing roll. Then, it was put into a steam-heated stretching tank at 120° C., and stretched to 1.74 times with a third stretching roll to perform a two-stage stretching of 12 times in total.

[0087] Next, use a pair of upper and lower file pattern embossing rolls (φ101mm, width 160mm, circumferential convexity interval 2.93mm, width convexity interval 1.33mm, convexity height 0.9mm, and the tip of the convexity The shape is a rhombus wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com