Glass fiber sizing agent and application thereof

A technology of glass fiber and sizing agent, applied in the field of glass fiber sizing agent for sewage degradation tanks, to achieve the effect of beautiful surface, uniform distribution of glass fiber, and excellent fiber opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

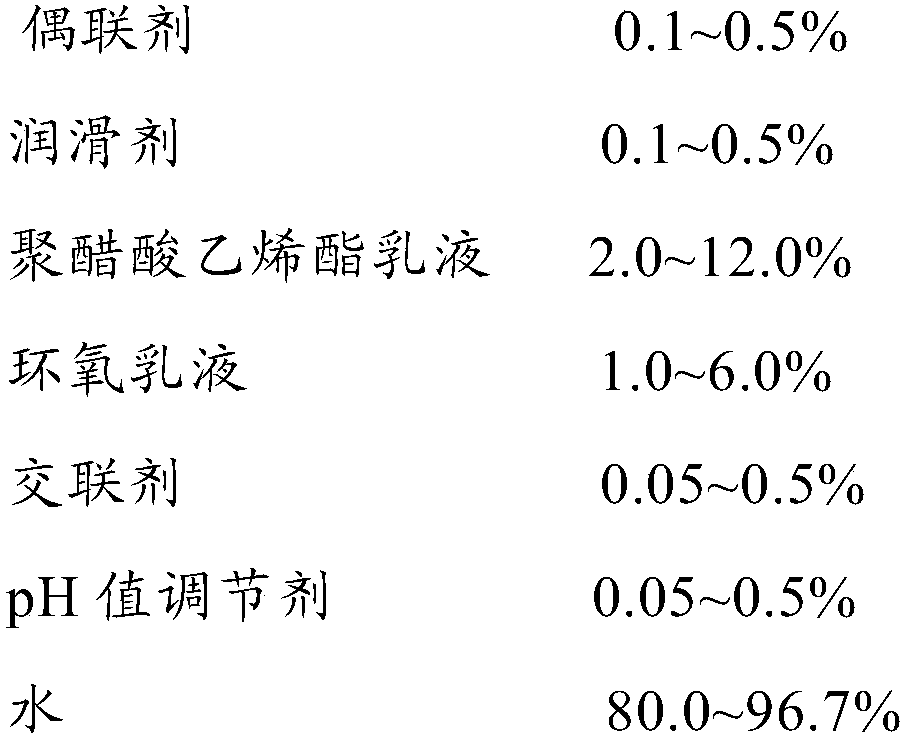

[0058] A glass fiber sizing agent, comprising coupling agent, lubricant, polyvinyl acetate emulsion, epoxy emulsion, crosslinking agent, pH regulator and water, wherein the content of each component is expressed as follows in mass percent:

[0059]

[0060] The glass fiber composite material prepared by the glass fiber sizing agent in Example 1 has a glass fiber content of 25.07%, a hairiness of 8.6 mg / kg, an unnotched impact strength of 63.4 MPa, and a tensile strength of 101 MPa. The glass fiber content is high and evenly distributed. The surface is smooth and the overall appearance is good.

Embodiment 2

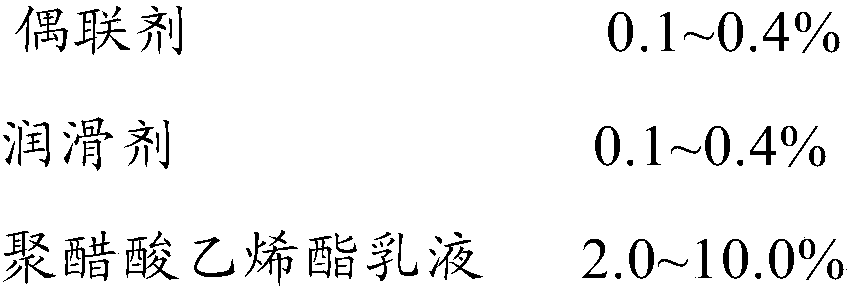

[0062] A glass fiber sizing agent, comprising coupling agent, lubricant, polyvinyl acetate emulsion, epoxy emulsion, crosslinking agent, pH regulator and water, wherein the content of each component is expressed as follows in mass percent:

[0063]

[0064] The glass fiber composite material prepared by the glass fiber sizing agent in Example 2 has a glass fiber content of 18.83%, a hairiness of 6.12mg / kg, an unnotched impact strength of 60.6MPa, and a tensile strength of 105.8MPa, and the low hairiness of the prepared glass Fiber composites have better bundling properties.

Embodiment 3

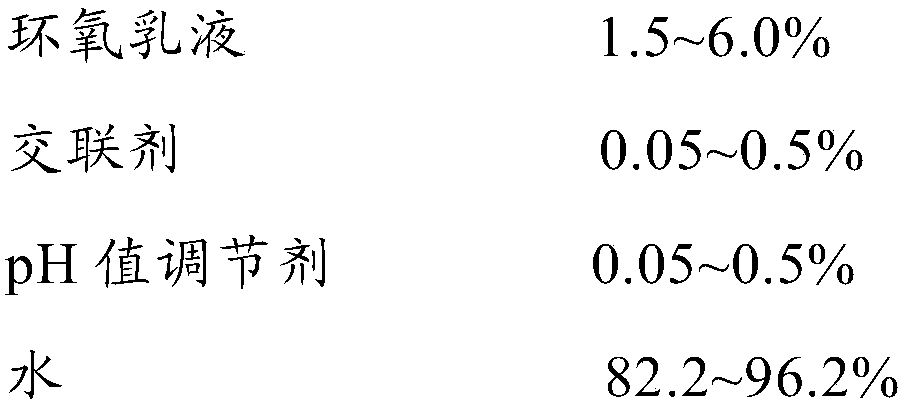

[0066] A glass fiber sizing agent, comprising coupling agent, lubricant, polyvinyl acetate emulsion, epoxy emulsion, crosslinking agent, pH regulator and water, wherein the content of each component is expressed as follows in mass percent:

[0067]

[0068] The glass fiber composite material prepared by the glass fiber sizing agent in Example 3 has a glass fiber content of 19.63%, a hairiness of 7.55mg / kg, an unnotched impact strength of 73.56MPa, and a tensile strength of 110.6MPa. The prepared glass fiber composite material has Better mechanical properties.

[0069] Among them, the coupling agent used in the glass fiber sizing agent in the embodiment of the present invention is γ-methacryloxypropyltrimethoxysilane whose production model is MEMO and γ-aminopropyl triethylsilane whose production model is AMEO. One or two of oxysilanes, the lubricant is polyimide lubricant, the crosslinking agent is F42, the polyvinyl acetate emulsion is JS-135 and JS218-2 of CELENESE, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com