Carpet edge cutting mechanism with water spraying function

A technology of edge trimming and water spraying, applied in the mechanical field, can solve the problems of undisclosed edge trimming and leftover materials without clear instructions, etc., and achieve the effect of good effect, uniform watering, and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

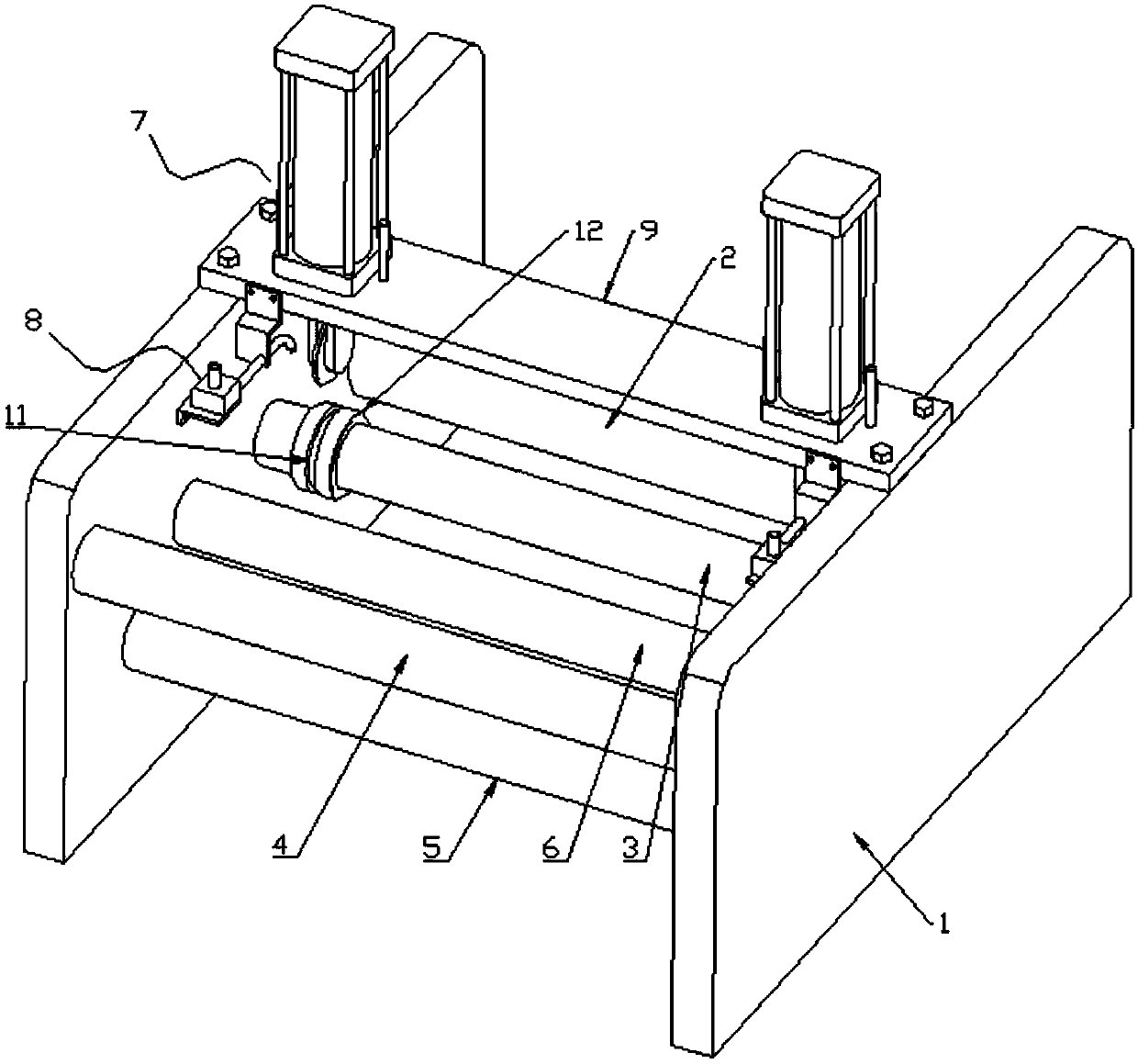

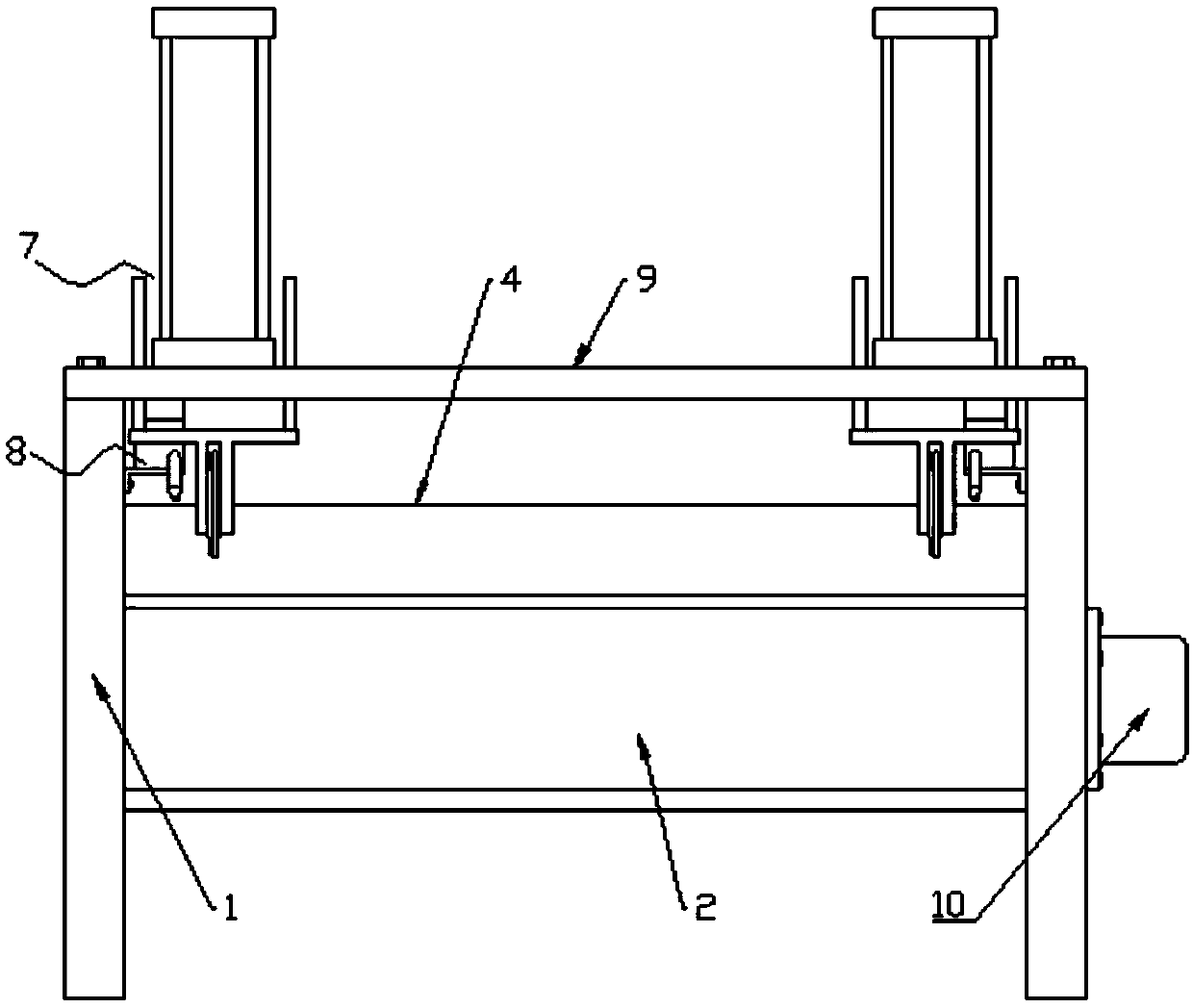

[0027] Such as Figure 1 to Figure 4 As shown, a carpet edge trimming mechanism with water spraying function includes a frame 1, a driving roller 2, an edge trimming roller 3, an edge trimming mechanism 7, a water spraying mechanism 8 and several driven rollers, and the driving roller 2 , edge trimming roller 3 and several driven rollers are rotatably connected in frame 1, edge trimming roller 3 is positioned between driving roller 2 and driven roller, and wherein one end of driving roller 2 is connected to driving motor 10, and described cutting Two ring sleeves 12 are symmetrically arranged on the side roller 3, and an annular cutter groove 11 is arranged on the ring sleeve 12, and a transverse support 9 is also installed on the top of the frame 1 and is located directly above the edge trimming roller 3;

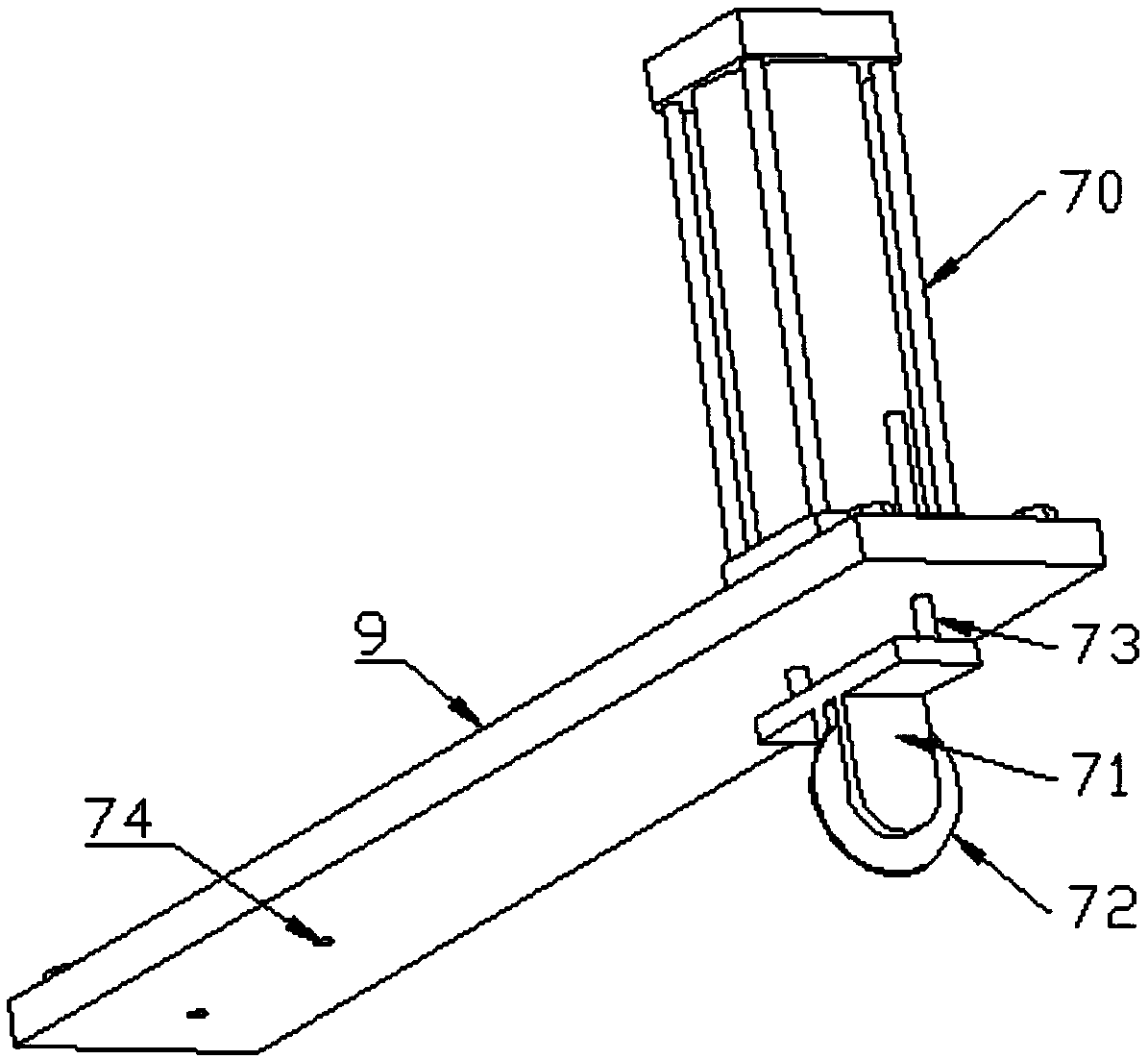

[0028] Described trimming mechanism 7 has two and is arranged symmetrically, and it specifically comprises telescopic mechanism 70, cutter frame 71 and cutter 72, and tele...

Embodiment 2

[0033] Such as image 3 , Figure 5 , Figure 6 and Figure 7 As shown, a carpet edge trimming mechanism with water spraying function includes a frame 1, a driving roller 2, an edge trimming roller 3, an edge trimming mechanism 7, a water spraying mechanism 8 and several driven rollers, and the driving roller 2 , edge trimming roller 3 and several driven rollers are rotatably connected in frame 1, edge trimming roller 3 is positioned between driving roller 2 and driven roller, and wherein one end of driving roller 2 is connected to driving motor 10, and described cutting Two ring sleeves 12 are symmetrically arranged on the side roller 3, and an annular cutter groove 11 is arranged on the ring sleeve 12, and a transverse support 9 is also installed on the top of the frame 1 and is located directly above the edge trimming roller 3;

[0034] Described trimming mechanism 7 has two and is arranged symmetrically, and it specifically comprises telescopic mechanism 70, cutter fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com