Fiber sizing agent composition

A composition and fiber technology, which is applied in the field of fiber sizing agent, can solve the problems at the same time, and achieve the effects of quality improvement, excellent impregnation, and good bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

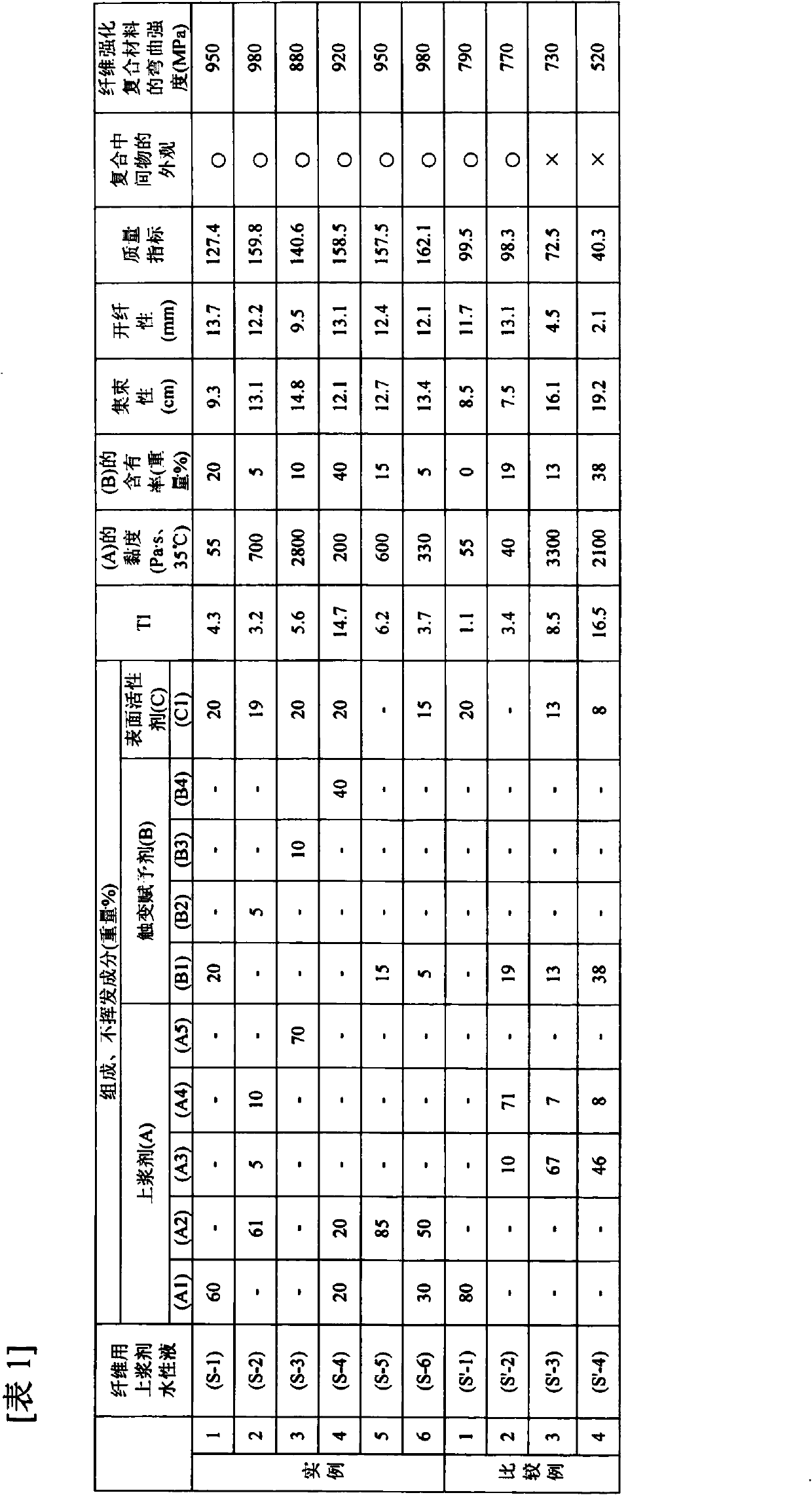

Examples

manufacture example 1

[0096] Polyester resin (A2):

[0097] Bisphenol A ethylene oxide 2 mole adduct "Newpol BPE-20" (trade name) [manufactured by Sanyo Chemical Industry Co., Ltd.] 2,212 parts by weight, 996 parts by weight of terephthalic acid (alcohol / acid = 7 / 6 molar ratio) and 3 parts by weight of potassium oxalate titanate were reduced to 0.001 MPa in a glass reaction vessel at 230° C., and reacted for 15 hours while distilling off water. 1,500 parts by weight of polyoxyethylene glycol "PEG1500" (trade name) [manufactured by Sanyo Chemical Industry Co., Ltd.] was further added thereto, and the reaction was carried out at 180°C under normal pressure for 10 hours to obtain 4,490 parts of polyester resin (A2). parts by weight.

[0098] The viscosity at 35° C. of (A2) was 700 Pa·s.

[0099] The compositions of the sizing agent (A), the thixotropy imparting agent (B), and the surfactant (C) used in the following examples are as follows.

[0100] Sizing agent (A);

[0101] Bisphenol A type epox...

example 1

[0129] Put 600 parts by weight of epoxy resin (A1), 200 parts by weight of higher fatty acid amide (B1), and 200 parts by weight of surfactant (C1) into a universal mixer [manufactured by Sanying Works (Stock)], at 130 ° C After uniformly mixing for 30 minutes, the mixture was cooled to 50° C. to obtain a sizing agent composition (E1) for fibers. Next, 1,500 parts by weight of water was added dropwise to (E1) over 6 hours to obtain 2,500 parts by weight of an aqueous sizing agent solution (S-1) for fibers having a nonvolatile content concentration of 40% by weight. The viscosity at 35° C. of (A1) was 55 Pa·s.

example 2

[0131]Put 650 parts by weight of polyester resin (A2), 50 parts by weight of fatty acid ester (B2), 50 parts by weight of polyether resin (A4), and 200 parts by weight of surfactant (C1) into a universal mixer [Sanying Manufacturing Co., Ltd. (Stock) Manufacturing], uniformly mixed at 50°C for 30 minutes. Then, 1,450 parts by weight of water was added dropwise over 6 hours, and 100 parts by weight of polyurethane emulsion (A3) was added thereto to obtain an aqueous sizing agent for fibers with a non-volatile component concentration of 42% by weight (S-2 ) 2,500 parts by weight. The viscosity at 35 degreeC of (A) component [the non-volatile matter of the mixture of said (A2), (A4), (A3)] was 700 Pa*s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com