Preparation method for polyamide-modified epoxy resin emulsion

A technology of epoxy resin emulsion and polyamide resin, which is applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of poor heat resistance and toughness, and achieve high heat resistance, strong toughness, and excellent bundling properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

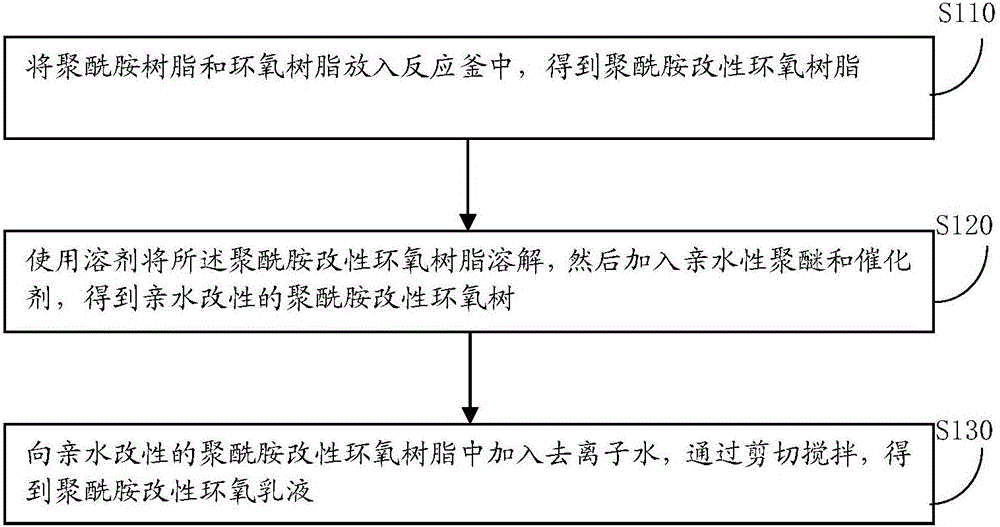

[0024] Such as figure 1 as shown, figure 1 A schematic flow diagram of a method for preparing a polyamide-modified epoxy resin emulsion is provided for the embodiment of the present application. The method for preparing a polyamide-modified epoxy resin emulsion provided in the embodiment of the present application includes:

[0025] Step 110: Put the polyamide resin and epoxy resin into a reaction kettle to obtain a polyamide-modified epoxy resin.

[0026] Specifically, determine that the molar weight of hydrogen repellent in the polyamide resin is a, and determine that the epoxy group molar weight of the epoxy resin is b; The amide resin and the epoxy resin are put into a reaction kettle to obtain the polyamide-modified epoxy resin.

[0027] Step 120, using a solvent to dissolve the polyamide-modified epoxy resin, and then adding a hydrophilic polyether and a catalyst to obtain a hydrophilic-modified polyamide-modified epoxy resin.

[0028] Specifically, the polyamide-modi...

Embodiment 1

[0039] (1) Add 10g of polyamide resin 650 (the active hydrogen molarity is 0.051 moles) and 100g bisphenol A epoxy E51 (the epoxy group molarity is 0.51 moles) into a four-necked flask, and heat up under stirring to 120° C. and react for 2 hours to obtain a polyamide-modified epoxy resin.

[0040] (2) After the prepared polyamide modified epoxy resin solution is cooled to 40°C, add 40g of acetone, 0.24g of boron trifluoride ether solution and 66g of an average molecular weight of 2000 polyethylene glycol resin, after completely mixing, After stirring and reacting at 40° C. for 2 hours, acetone was distilled off to obtain a hydrophilic-modified polyamide-modified epoxy resin.

[0041](3) The polyamide-modified epoxy resin of hydrophilic modification is warmed up to 60 ℃, after adding 30% deionized water of resin quality and stirring evenly, cool down to 40 ℃, then add 30% of resin quality in the mixing system again 1 times of deionized water post-stirring or high-shear emulsif...

Embodiment 2

[0043] (1) Add 10g polyamide resin 250 (wherein the active hydrogen molarity is 0.092 moles) and 110g bisphenol A type epoxy E51 (the epoxy group molarity is 0.56 moles) into a four-necked flask, and heat up under stirring After reacting for 3 hours at 100° C., a polyamide-modified epoxy resin was obtained.

[0044] (2) After cooling the prepared polyamide-modified epoxy resin solution to 20°C, add 100g of dichloromethane, 0.6g of boron trifluoride ether solution and 60g of polyethylene glycol resin with an average molecular weight of 4000, and keep it at 20°C After reacting with stirring for 4 hours, the methylene chloride was distilled off to obtain a hydrophilic-modified polyamide-modified epoxy resin.

[0045] (3) Heating the hydrophilic modified polyamide-modified epoxy resin to 40° C., adding deionized water twice the mass of the resin, stirring or high-shear emulsification to prepare a polyamide-modified epoxy emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com