Power battery system and charging method for optimizing heating strategy through low-temperature charging

A technology of power battery and charging method, which is applied in the charging field of power battery system and low-temperature charging optimization heating strategy, can solve the problems of long charging time at low temperature, long charging time, unreasonable heating strategy, etc., and achieve short charging time and shorten charging time, to avoid the effect of repeatedly starting the heating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

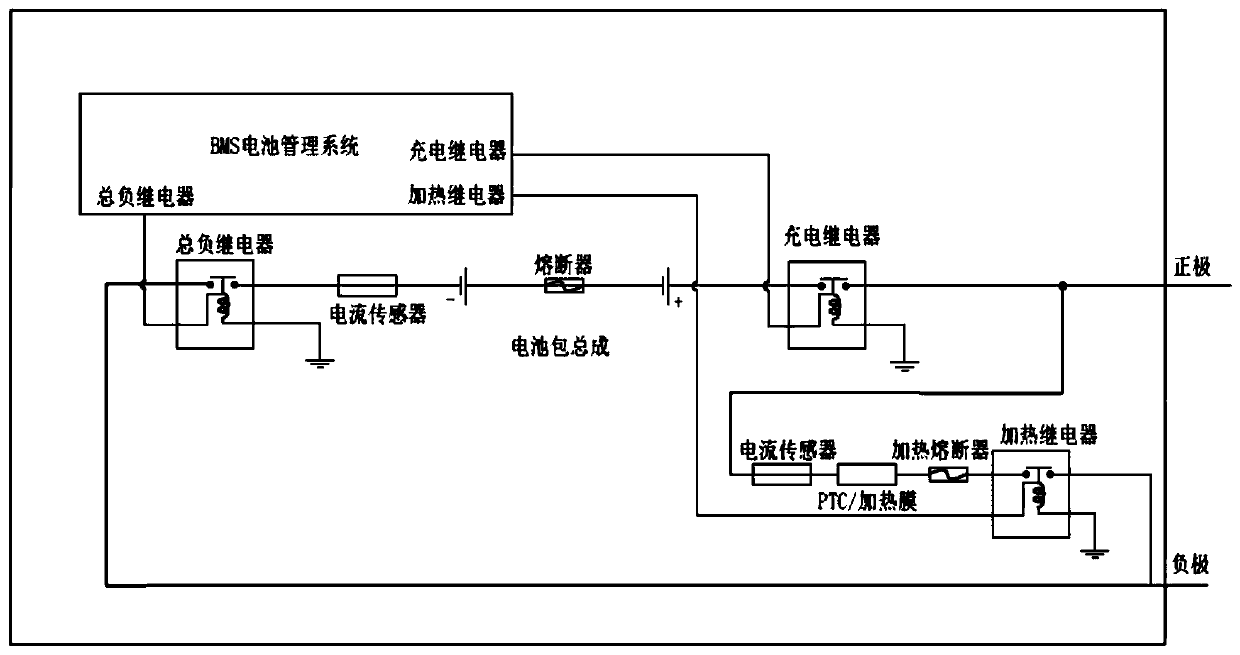

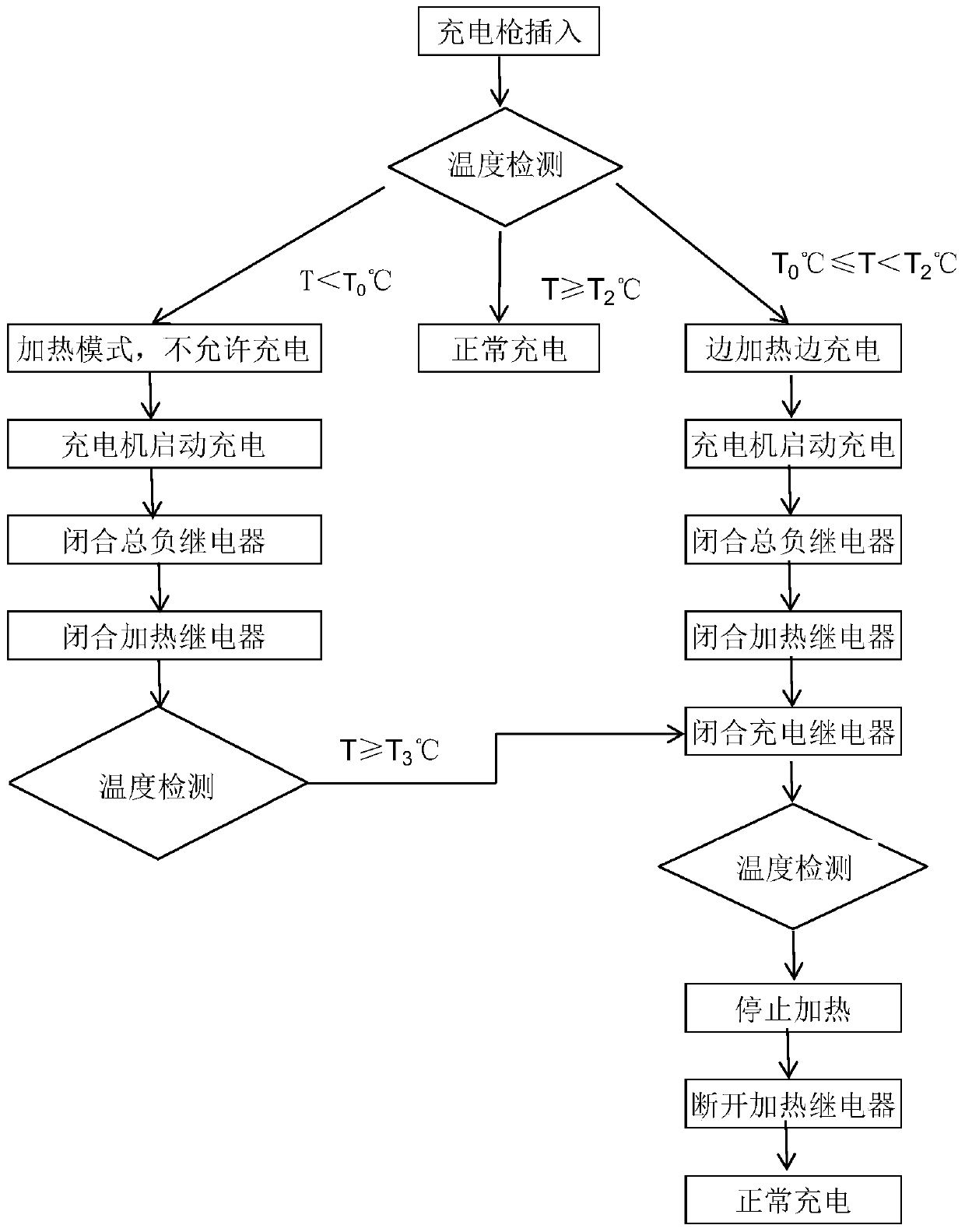

[0031]Embodiment: A low-temperature charging optimization heating strategy charging method for charging a power battery system under low temperature conditions. The power battery system includes a charging circuit, a heating circuit, and a battery management system. The charging circuit is equipped with a total negative relay, a charging relay, a current sensor, and a fuse. The heating circuit is equipped with a heating system. The heating system includes a heating relay, a heater, and a current sensor. , Fuse, heating circuit and total negative relay, charging relay are set in parallel. The heater is a PTC heating plate or heating film, and the current sensor on the charging circuit and the current sensor on the heating circuit are connected to the battery management system. The total negative relay, charging relay, and heating relay are all connected to the battery management system, and the battery management system can collect the battery temperature in the power battery s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com