Microporous heater structure

A heater and microporous technology, applied in heating methods, heating elements, heating element materials, etc., can solve the problems of potential safety hazards, large power consumption, heavy weight, etc., and achieve light weight, safe use, and high heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

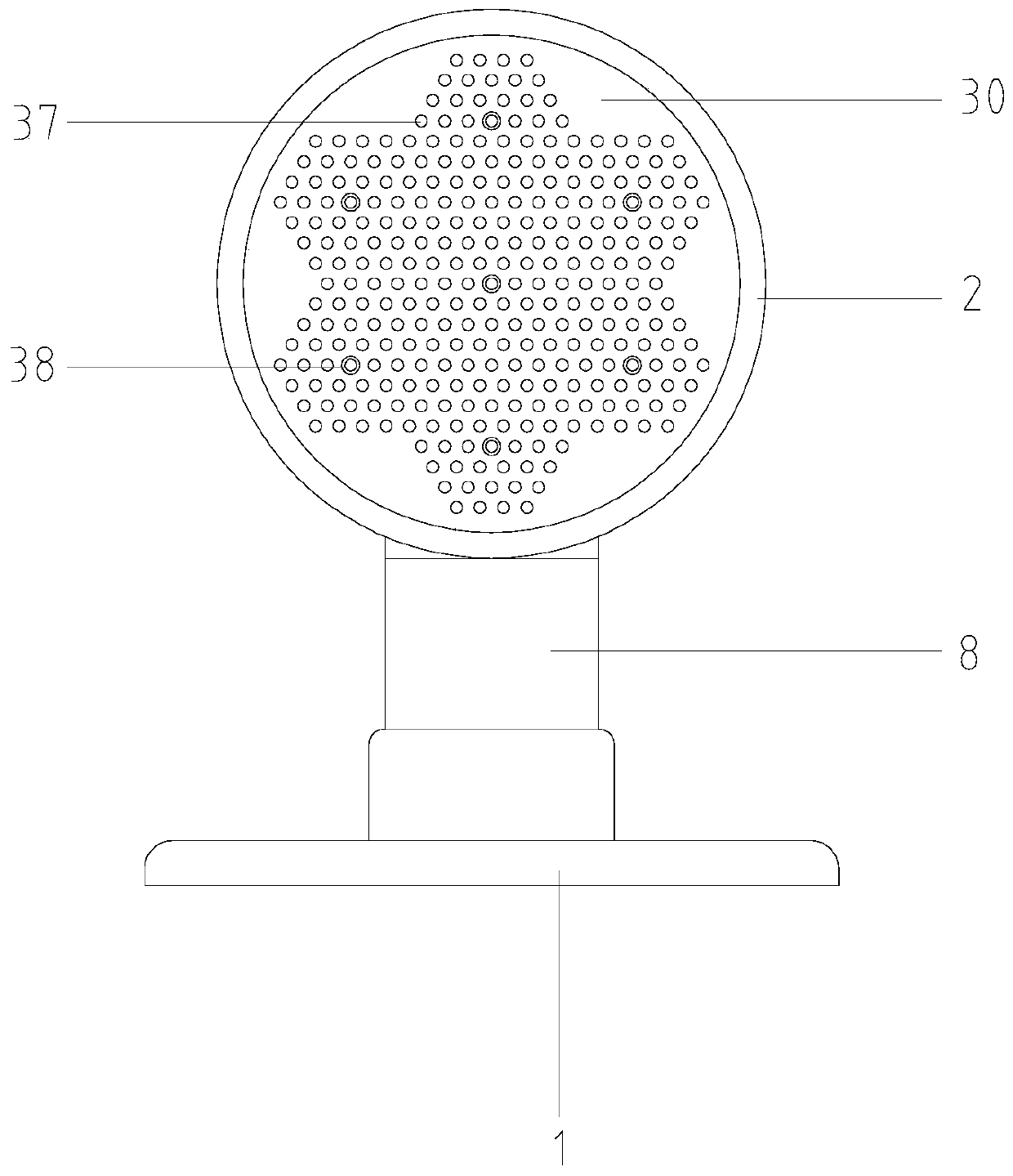

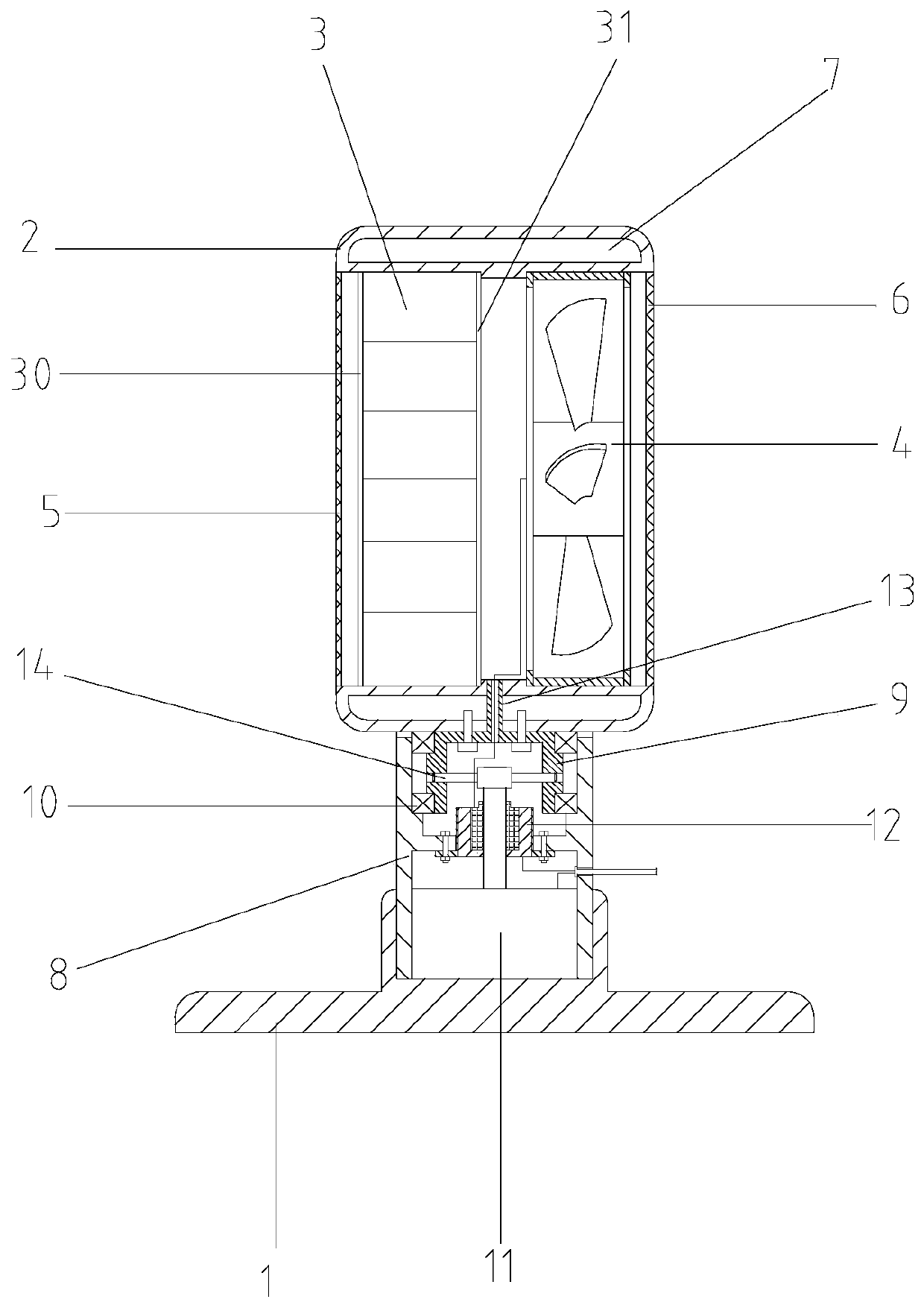

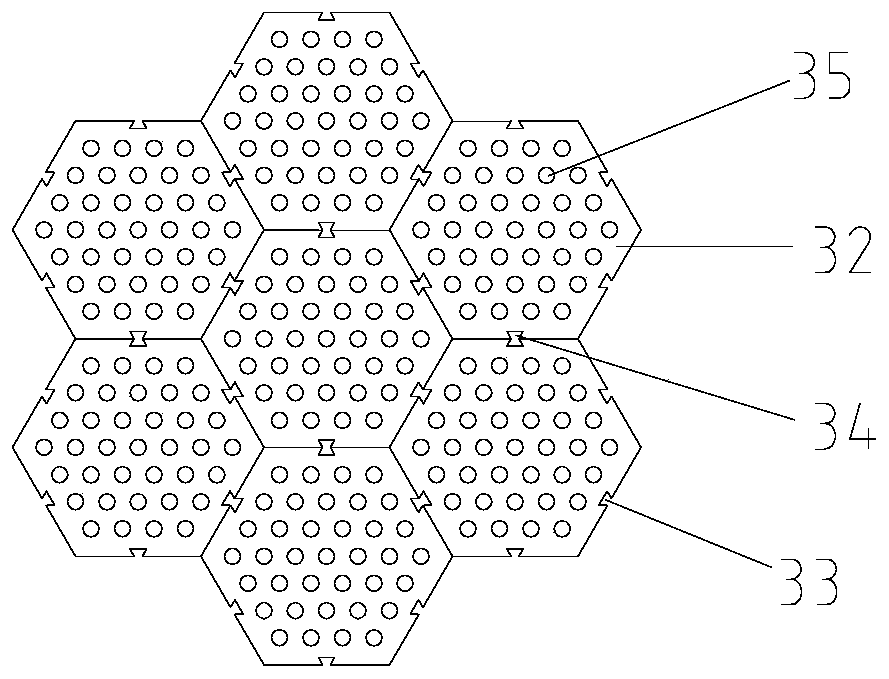

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 The structure of a microporous heater shown includes a base 1 and a shell 2 arranged on the upper end of the base. The shell 2 is provided with a heater body 3. The heater body 3 includes a front electrode plate 30, a rear electrode plate 31, and a Some ceramic membrane substrates 32 between the front electrode plate and the rear electrode plate, micropores are distributed in the ceramic membrane substrates 32, and graphene powder is filled in the micropores, and the ceramic membrane substrates 32 are columnar. The ceramic membrane substrates in this embodiment 32 is in the shape of a hexagonal column, and each side of the ceramic membrane substrate 32 is provided with a dovetail connection groove 33, and the dovetail connection grooves 33 on the sides where two adjacent ceramic membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com