Full pre-mix condensing heating hot-water dual-purpose device

A fully premixed condensing, dual-purpose device technology, applied in water heaters, indirect heat exchangers, fluid heaters, etc., can solve the problems of difficult promotion and high manufacturing costs, achieve low cost, protect the environment, reduce The effect of exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

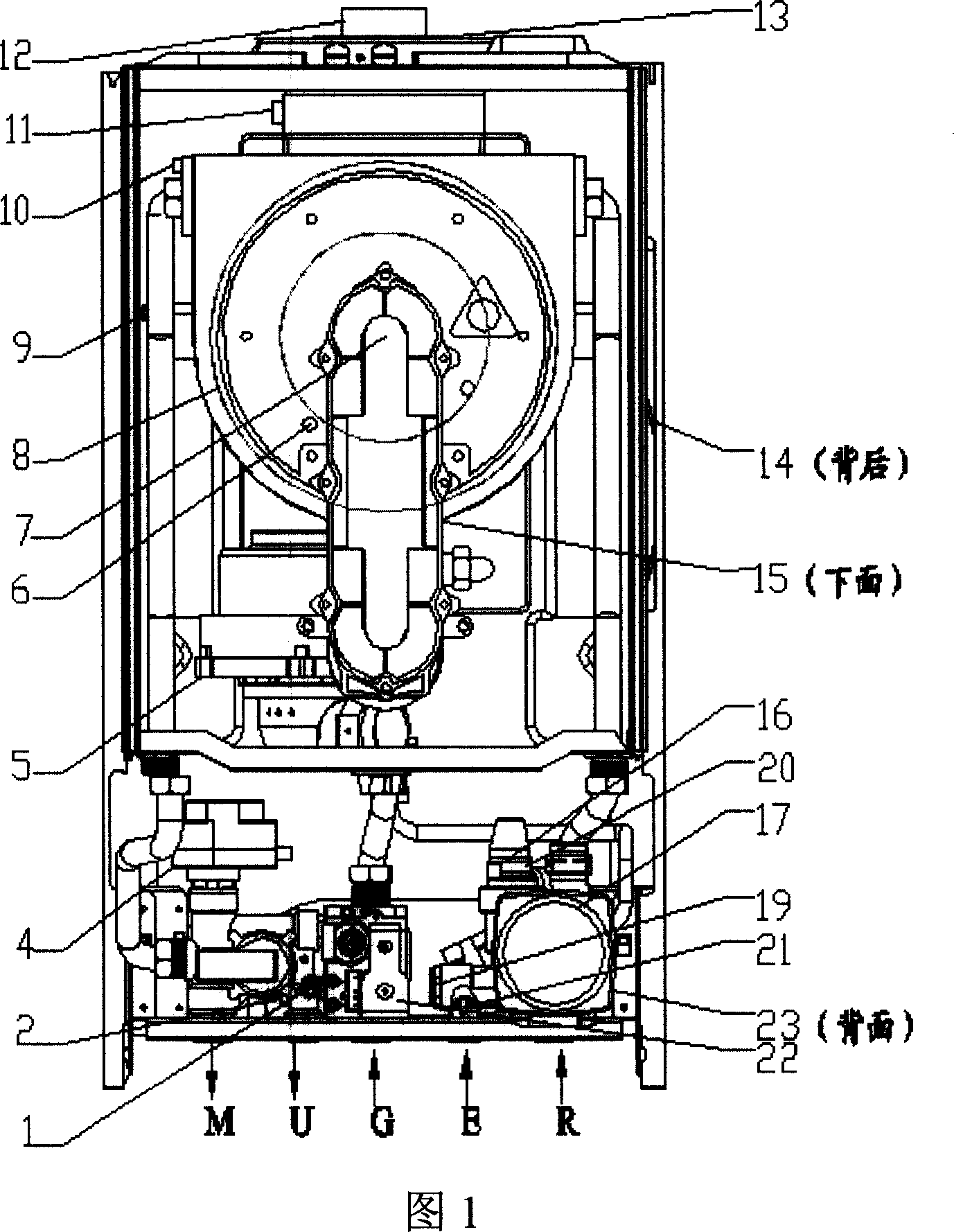

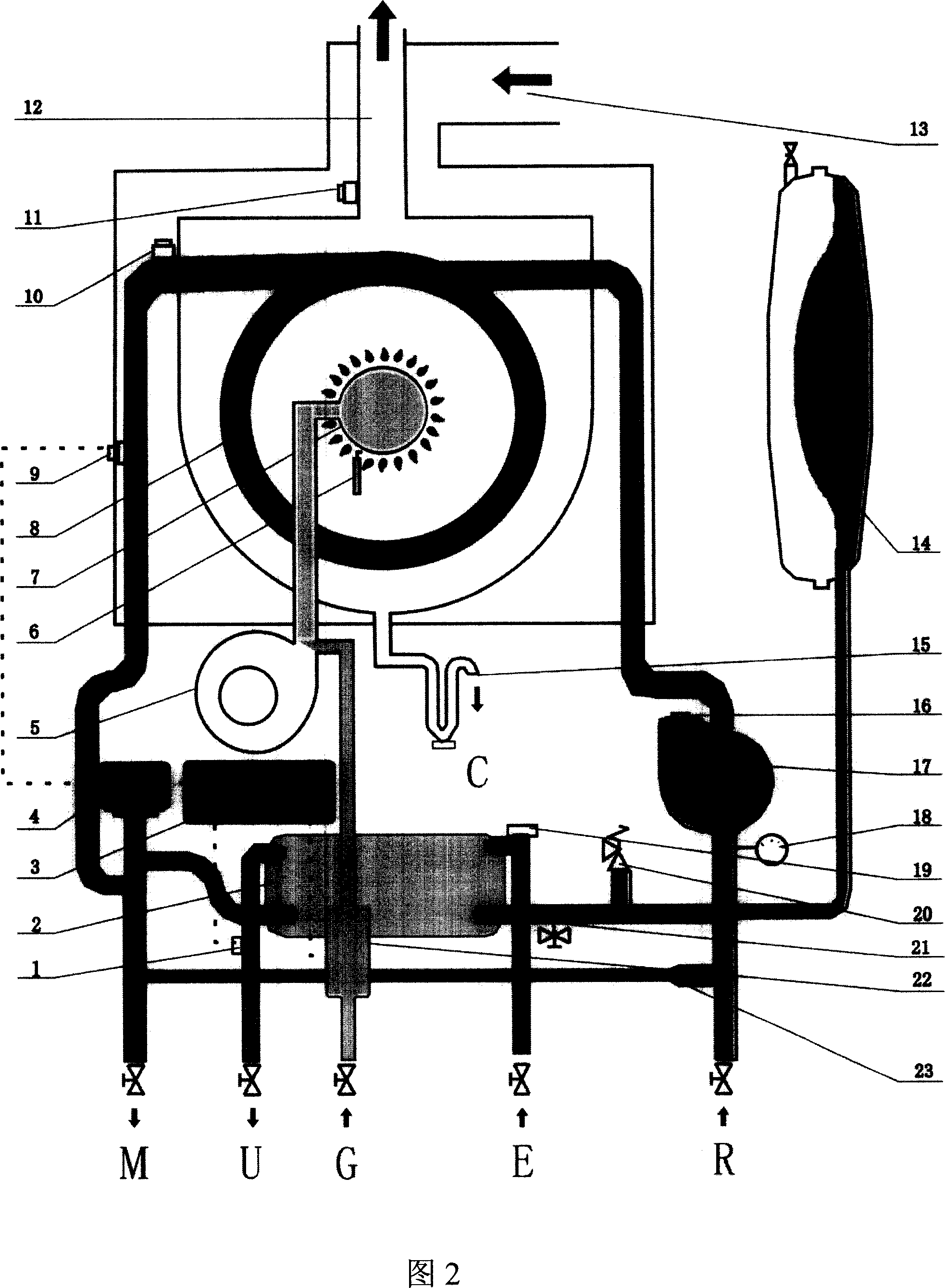

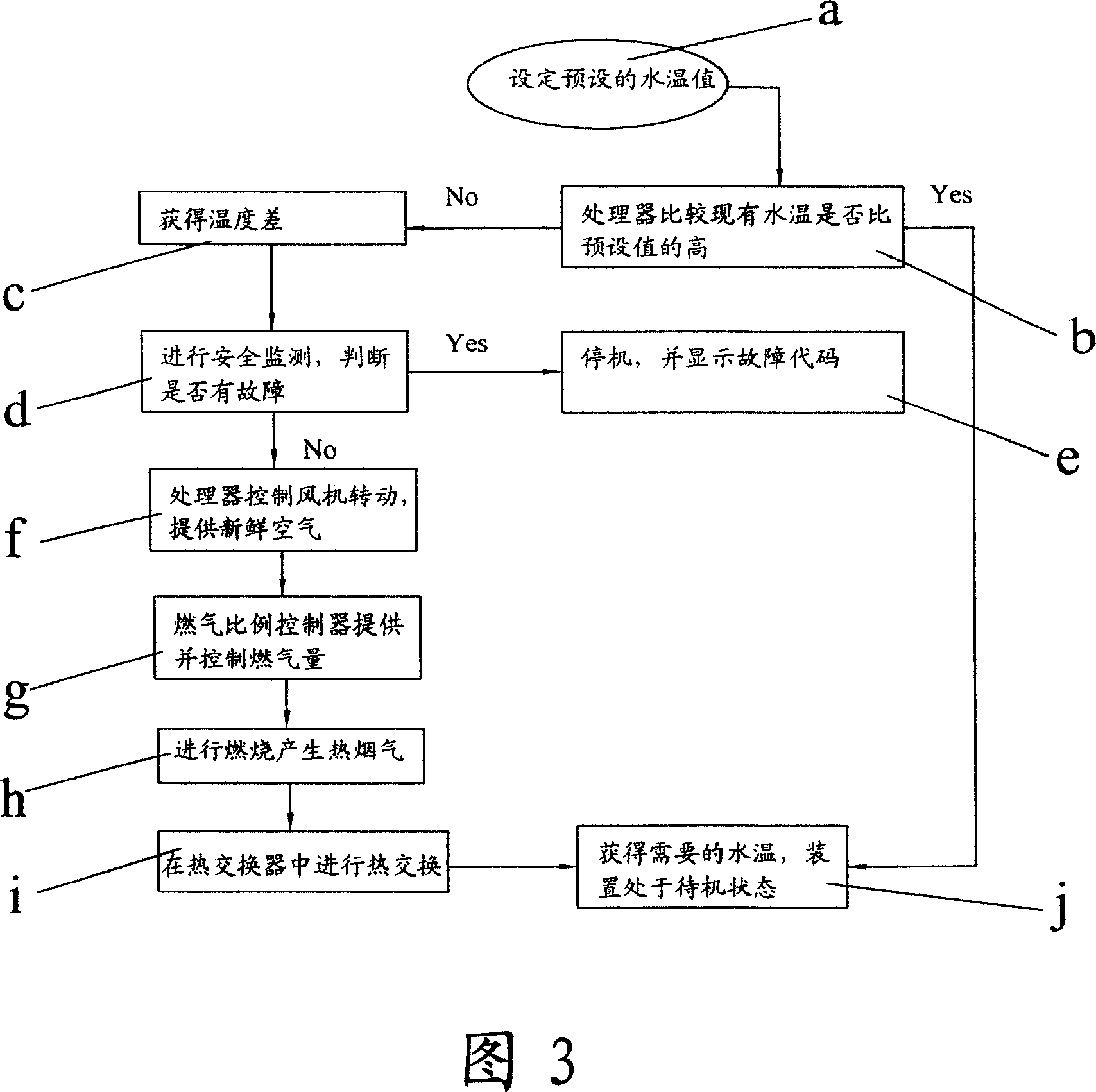

[0034] Please refer to Figure 1, which is a structural diagram of a fully premixed condensing heating and hot water dual-purpose device of the present invention; it includes a combustion generation part, a circulation delivery part, a heat exchange part, a control part and a safety auxiliary device. The combustion generation part is mainly used for combustion to provide the working heat of the heating and hot water dual-purpose device, which includes a full premix burner 7 and a gas-air ratio controller 22;

[0035] The main function of the heat exchange part is to realize heat exchange between hot flue gas and water, which includes a heat exchanger and a plate heat exchanger 2;

[0036] The circulation conveying part mainly provides circulation space for smoke, gas and water and provides power, which includes smoke three-way valve motor 4, DC frequency conversion fan 5, smoke exhaust pipe 12, air inlet pipe 13, condensed water discharge Pipe 15 and circulating water pump 17; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com