Converter large scrap ratio smelting composite slagging heat supplementing agent and preparation and use method thereof

A technology of scrap steel ratio and heating agent, which is applied in the field of converter steelmaking, can solve the problems of no heating agent, etc., achieve low heating cost, shorten the smelting cycle, and reduce the consumption of converter heating agent and flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

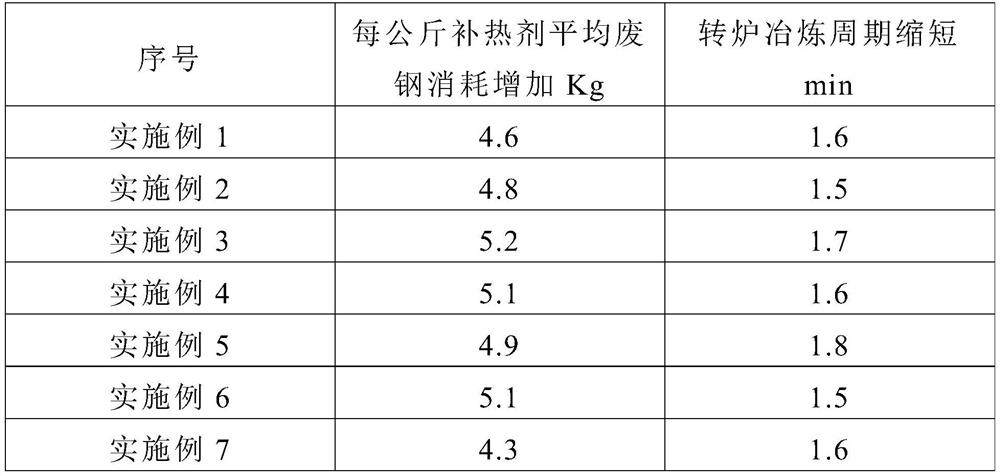

Examples

Embodiment 1

[0040] A composite slag-forming heat supplement for converter smelting with large scrap ratio is prepared from the following raw materials by weight percentage: 55% of silicon-aluminum-calcium-carbon alloy, 10% of sintered calcium aluminate, 8% of wood charcoal, 6% of sintered return ore, Manganese ore 13%, light burning dolomite 7.5%, sodium stearate 0.5%.

[0041] The silicon-aluminum-calcium-carbon alloy is composed of Si, Al, Ca, C and Fe, and the impurity elements are P, S, among which, the weight percentage content range of Si, Al, Ca, and C is: Si, 35%, Al, 12%, Ca, 18%, C, 9%, the weight percentage content range of metal Fe is: 25%, the weight percentage content range of impurity elements P and S is: P≤0.05%, S≤0.1%.

[0042] The composition of sintered calcium aluminate is 12CaO 7Al 2 O 3 , 12CaO 7Al 2 O 3 The weight percent is 85%.

[0043] Among them, wood charcoal is a carbonaceous material obtained by distillation from vitex wood as raw material, sintered ore...

Embodiment 2

[0053]A composite slag-making heat supplement for converter smelting with large scrap ratio is prepared from the following raw materials by weight: 60% of silicon-aluminum-calcium-carbon alloy, 12% of sintered calcium aluminate, 10% of wood charcoal, 5% of sintered ore, Manganese ore 7%, light burning dolomite 5.7%, sodium stearate 0.3%.

[0054] The silicon-aluminum-calcium-carbon alloy is composed of Si, Al, Ca, C and Fe, and the impurity elements are P and S. Among them, the weight percentage of Si, Al, Ca, and C ranges from: Si, 45%, Al, 10%, Ca, 9%, C, 12%, the weight percentage content range of metal Fe is: 24%, the weight percentage content range of impurity elements P and S is: P≤0.05%, S≤0.1%.

[0055] The composition of sintered calcium aluminate is 12CaO 7Al 2 O 3 , 12CaO 7Al 2 O 3 The weight percent is 83%.

[0056] Wood charcoal is a carbonaceous material obtained by distillation from wood chips as raw material. The sintered ore is the sintered sinter after c...

Embodiment 3

[0066] A composite slag-making heat supplement for converter high-waste steel ratio smelting is prepared from the following raw materials by weight percentage: 58% of silicon-aluminum-calcium-carbon alloy, 15% of sintered calcium aluminate, 5% of wood charcoal, 6.6% of sintered return ore, Manganese ore 10%, light burning dolomite 5%, sodium stearate 0.4%.

[0067] The silicon-aluminum-calcium-carbon alloy is composed of Si, Al, Ca, C and Fe, and the impurity elements are P and S. Among them, the weight percentage of Si, Al, Ca, and C ranges from: Si, 43%, Al, 10%, Ca, 19%, C, 12%, the weight percentage content range of metal Fe is: 15%, the weight percentage content range of impurity elements P and S are: P≤0.05%, S≤0.1%.

[0068] The composition of sintered calcium aluminate is 12CaO 7Al 2 O 3 , 12CaO 7Al 2 O 3 The weight percent is 82%.

[0069] Wood charcoal is a carbonaceous material obtained by distillation from wood blocks as raw materials. The sintered ore is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com