Preparation method of cupronickel strip for ship engine heat exchange

An engine and cupronickel technology, which is applied in the field of preparation of cupronickel strips for ship engine heat exchange, can solve the problems of serious peeling on the surface of the finished strips, affecting the use of domestic products, and failing to meet the comprehensive performance standards, so as to achieve the comprehensive performance of the strips. Superior, easy to mass industrial production, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

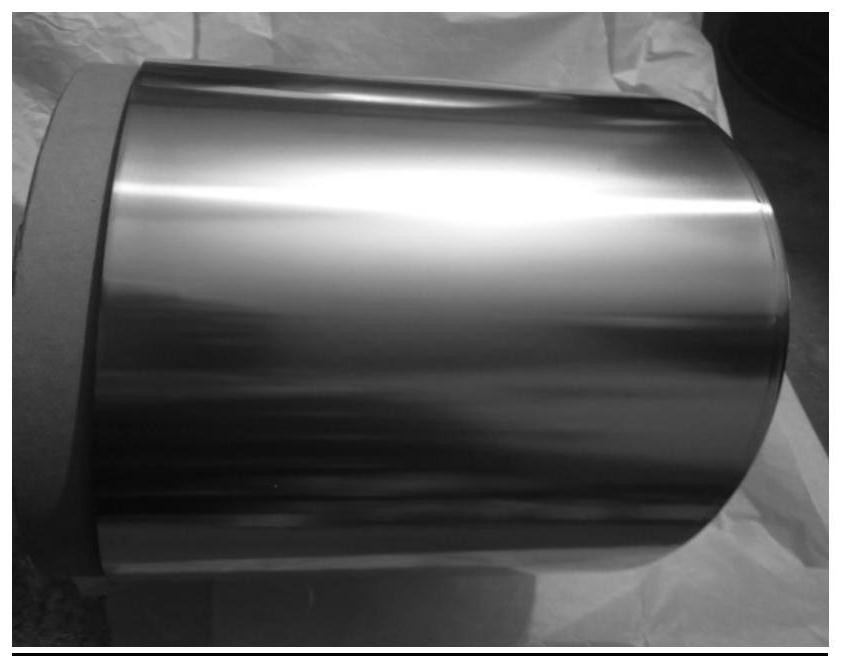

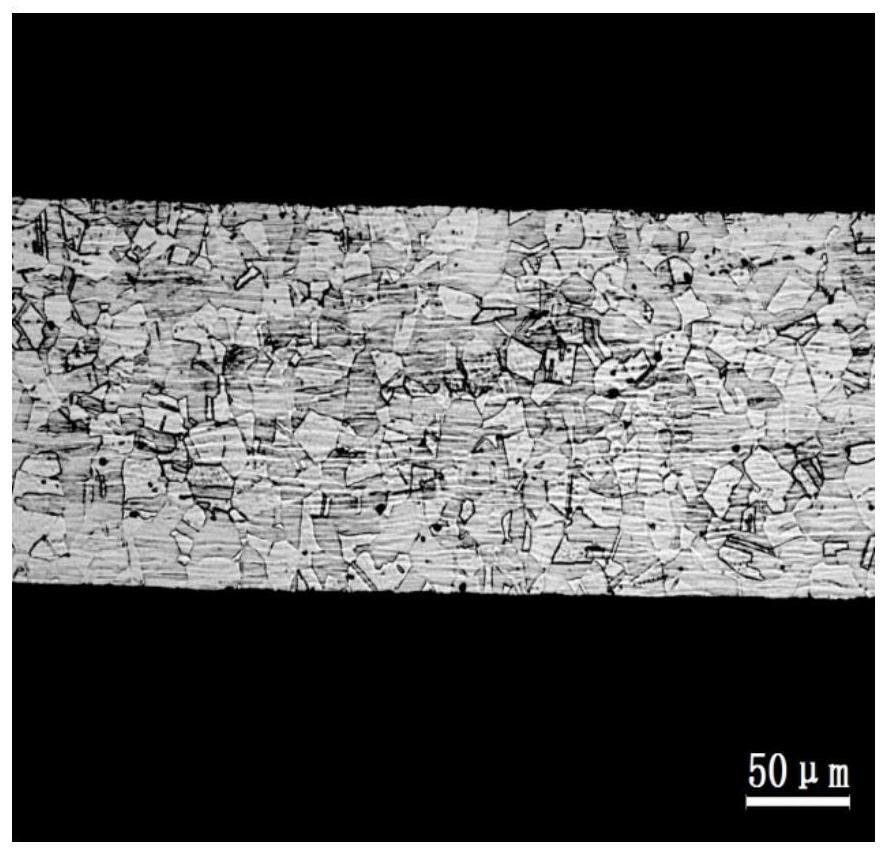

[0030] The embodiment of the present invention provides a method for preparing a cupronickel strip for ship engine heat exchange. The prepared cupronickel strip has specifications of 0.15×400×Lmm, 0.35×400×Lmm, and 1.56×400×Lmm, and the weight of a single roll is ≧500kg. δ mentioned in the embodiments of the present invention represents thickness, L represents length, and Φ represents diameter.

[0031] Specifically include the following steps:

[0032] Step 1: Mixing raw materials and smelting additives according to the following weight ratio, wherein the raw materials include cathode copper, electrolytic nickel, pure iron, and electrolytic manganese; the smelting additives include: carbon powder, pure titanium, nickel-magnesium alloy, and boron-iron alloy; The proportion of each component is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com