Infrared carbon crystal electronic heating panel and processing method thereof

A processing method and technology of carbon crystal heating sheets, applied in the direction of electric heating devices, ohmic resistance heating, chemical instruments and methods, etc., can solve the problems of low heat resistance temperature and heating efficiency of heating plates, and inability to obtain different temperature distribution areas, etc., to achieve Low cost, long service life, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1, prepare superconducting gel:

[0044] Weigh the following raw materials according to the parts by mass: 100g of flame-retardant high-temperature-resistant brominated epoxy resin, 50g of superconducting carbon crystal powder, 30g of magnesium hydroxide, 3.6g of dicyandiamide, and 283g of acetone, and grind and mix the above-mentioned raw materials to prepare into superconducting gel for use;

[0045] Step 2, prepare heating sheet:

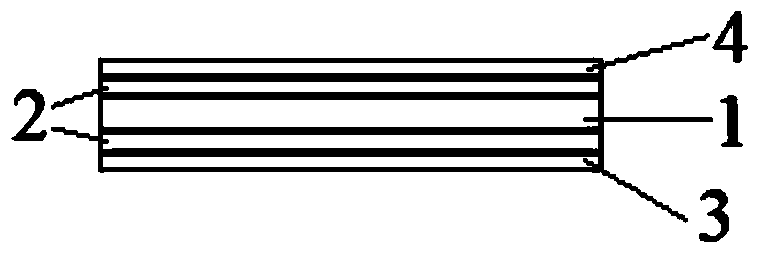

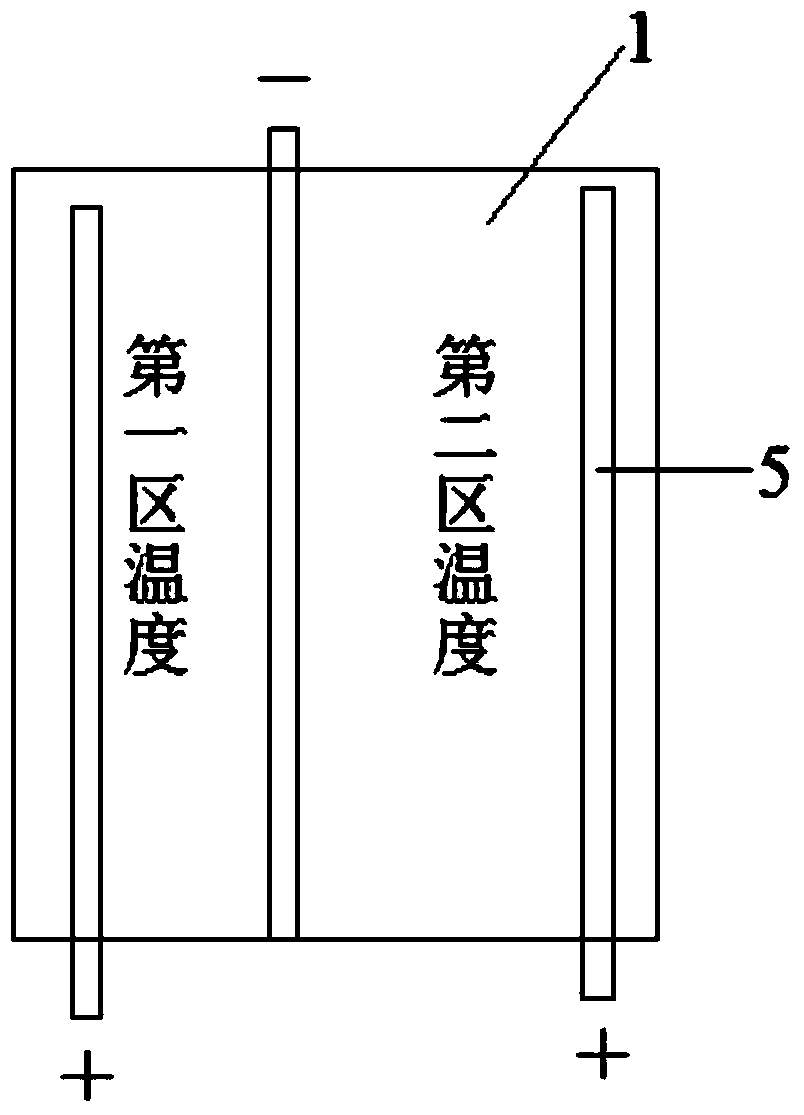

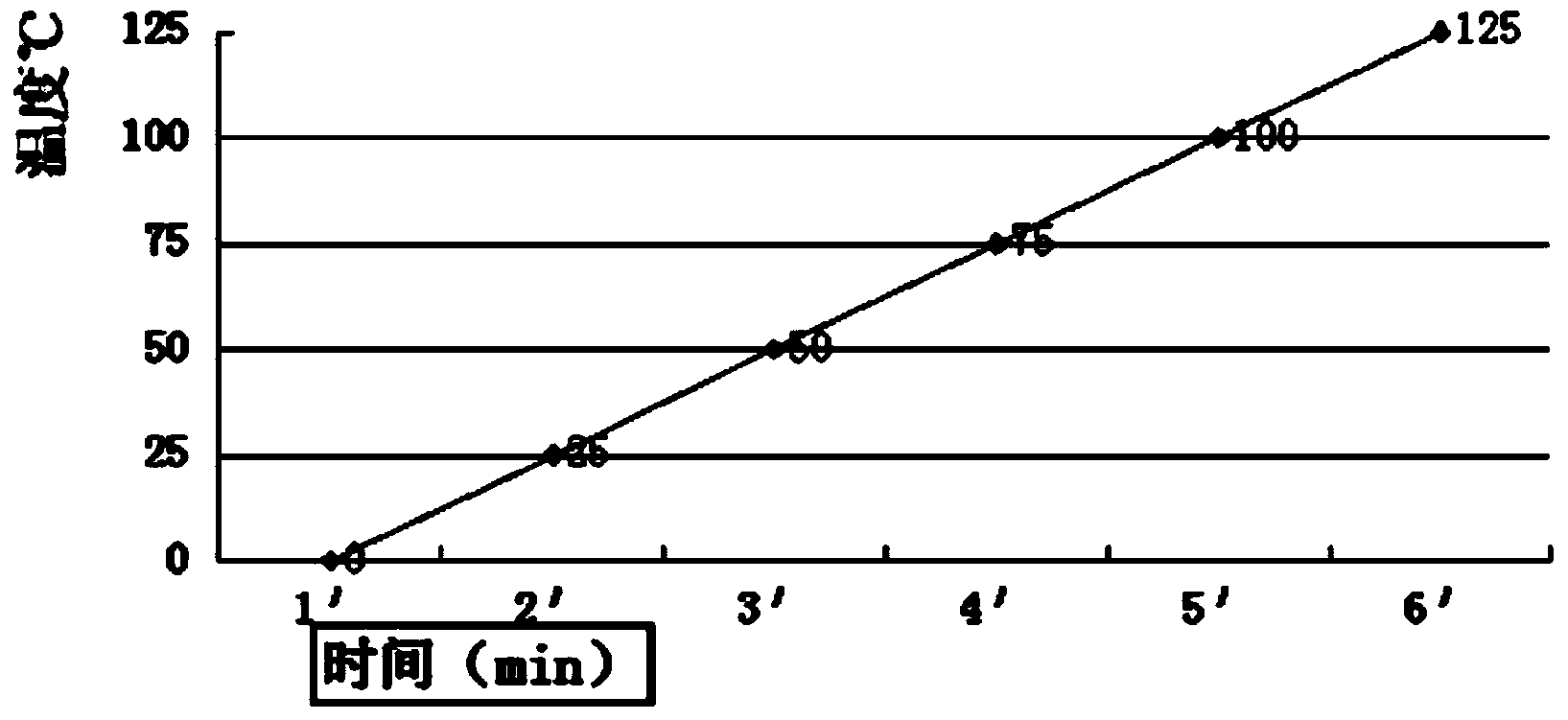

[0046] Use a gluing machine to dip and extrude the superconducting adhesive obtained in step 1 into a non-woven glass fiber cloth, dry it at 150°C, and then treat it for 90 minutes at a vacuum of 0.09MPa, a temperature of 180°C, and a pressure of 3MPa to obtain carbon crystals. Heating sheet, slice the carbon crystal heating sheet according to the required size and heating temperature, and then divide 3 copper wire electrodes on the carbon crystal heating sheet according to the requirements of heating power and temperature, and reser...

Embodiment 2

[0053] Step 1, prepare superconducting gel:

[0054] Weigh the following raw materials according to the parts by mass: 100g of flame-retardant high-temperature-resistant brominated epoxy resin, 100g of superconducting carbon crystal powder, 50g of magnesium hydroxide, 3.8g of dicyandiamide, and 430g of acetone, and grind and mix the above-mentioned raw materials to prepare into superconducting gel for use;

[0055] Step 2, prepare heating sheet:

[0056] Use a gluing machine to dip and extrude the superconducting adhesive obtained in step 1 into a non-woven glass fiber cloth, dry it at 160°C, and then treat it at a vacuum of 0.1MPa, a temperature of 170°C, and a pressure of 3.5MPa for 80min to obtain carbon Crystal heating sheet, slice the carbon crystal heating sheet according to the required size and heating temperature, and then divide 4 copper wire electrodes on the carbon crystal heating sheet according to the requirements of heating power and temperature, and reserve th...

Embodiment 3

[0062] Step 1, prepare superconducting gel:

[0063] Weigh the following raw materials according to the parts by mass: 100g of flame-retardant high-temperature resistant brominated epoxy resin, 75g of superconducting carbon crystal powder, 35g of magnesium hydroxide, 3.1g of dicyandiamide, and 300g of acetone, and grind and mix the above-mentioned raw materials to prepare into superconducting gel for use;

[0064] Step 2, prepare heating sheet:

[0065] Use a gluing machine to dip and extrude the superconducting adhesive obtained in step 1 into a non-woven glass fiber cloth, dry it at 170°C, and then treat it at a vacuum of 0.092MPa, a temperature of 190°C, and a pressure of 4MPa for 120min to obtain carbon crystals Heating sheet, slice the carbon crystal heating sheet according to the required size and heating temperature, and then divide 3 copper wire electrodes on the carbon crystal heating sheet according to the requirements of heating power and temperature, and reserve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com