Heating electrode paste, heating electrode and planar oxygen sensor comprising heating electrode

A technology for heating electrodes and slurry, which is applied in the field of oxygen sensors, can solve the problems of high cost of heating electrodes and low heating efficiency, and achieve the effects of cost reduction, high heating efficiency, and lower resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In the preparation method of the heating electrode slurry of the present invention, the inorganic powder and the organic slurry carrier are directly mixed evenly; wherein, the inorganic powder contains tantalum silicide, niobium alloy, aluminum oxide and silicon dioxide. In order to mix the components in the heating electrode slurry evenly, preferably, first mix the inorganic powder evenly and then ball mill to the required particle size; then mix the components in the organic slurry carrier evenly; finally mix the inorganic powder It is mixed with an organic slurry carrier, stirred evenly, and finally ground to obtain the heating electrode slurry of the present invention. In the present invention, there are no special restrictions on the grinding conditions. Preferably, the grinding conditions are such that the fineness of the obtained heating electrode slurry is less than 10 μm, and the viscosity of the heating electrode slurry is 120-250Pa. S. The term "fineness" is...

Embodiment 1

[0029] This example is used to illustrate the heating electrode slurry and its preparation method of the present invention.

[0030] (1) Take the inorganic powder according to the ratio in Table 1:

[0031] Table 1

[0032] Inorganic components

Tantalum silicide

Niobium alloy

Aluminum oxide

Silicon oxide

Lanthanum oxide

Ceria

Content (wt%)

85

3.5

6

4

0.8

0.7

Particle size (μm)

≤1.2

≤1.5

≤1.2

≤0.8

≤1.0

≤1.0

Median diameter (μm)

≤0.8

≤0.5

≤0.6

≤0.5

≤0.6

≤0.6

[0033] Mix the components in the inorganic powder in a planetary ball mill, and ball mill for 40 hours to obtain the inorganic component; wherein, the ball milling medium is absolute ethanol, the mass ratio of zirconia ceramic balls to the inorganic powder is 2:1, and the ball milling tank speed is 300rpm .

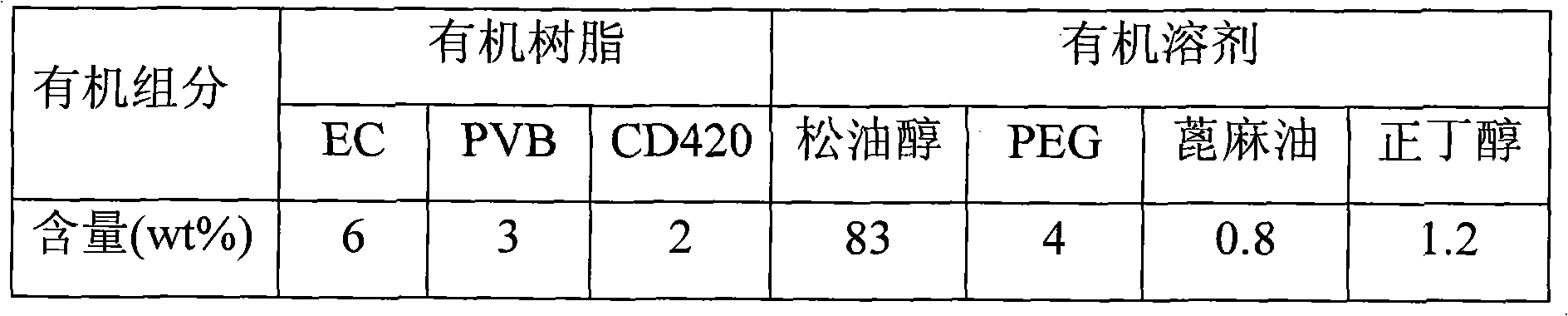

[0034] (2) take t...

Embodiment 2

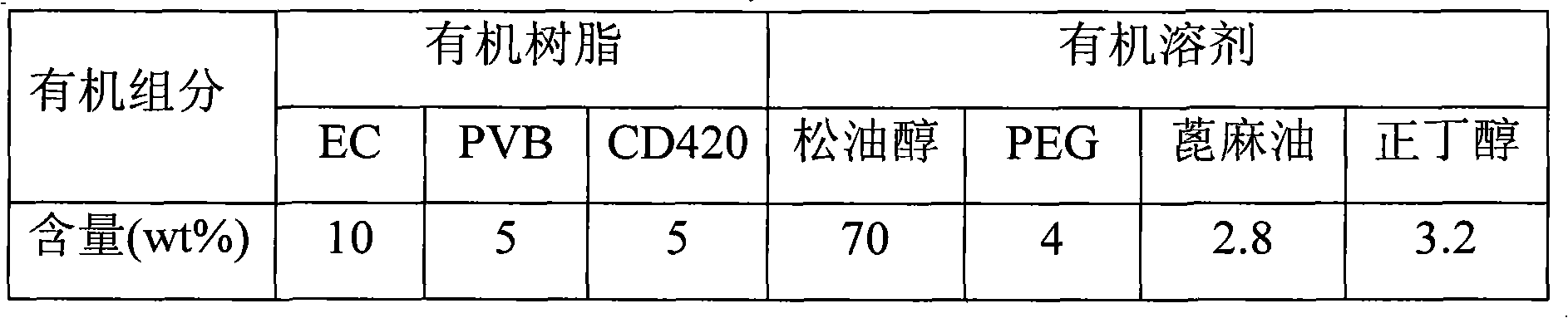

[0047] The same steps as in Example 1 were used to prepare the heating electrode slurry of this example, except that in step (1), the ratio of the inorganic components is shown in Table 4 below:

[0048] Table 4

[0049] Inorganic components

[0050] Through the above steps, the heating electrode slurry of this embodiment is obtained, which is denoted as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com