Sealing rubber strip for automobile window and preparation method of sealing rubber strip

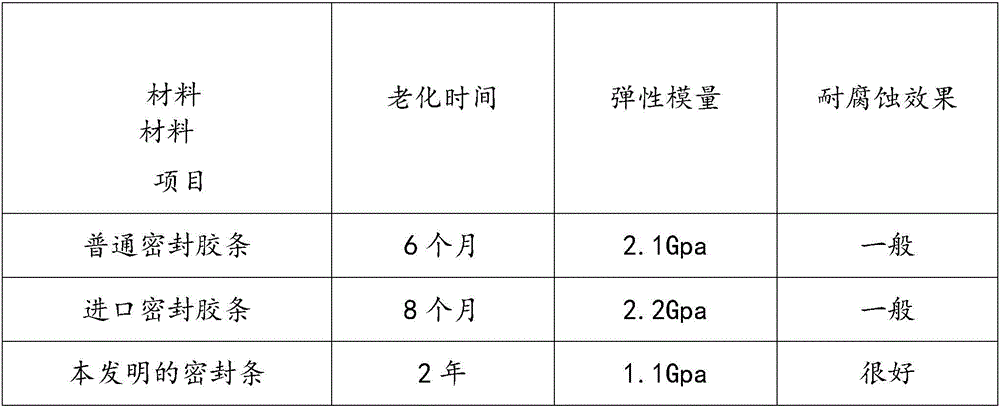

A technology for sealing strips and car windows, which is applied in the field of sealing strips for automobile windows and its preparation, which can solve the problems of poor elasticity, no air bubbles in the sealing strip, and corrosion-resistant materials, etc., and achieve long service life and elasticity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of sealing rubber strip of automobile window, is made of the following materials in proportion by weight, including 22 parts of polyvinyl chloride, 40 parts of EPDM rubber, 6 parts of paraffin wax, 7 parts of polypropylene adiene siloxane, 12 parts of tert-butyl hydroquinone, 18 parts of diisobutyl phthalate, 9 parts of mercapto ester, 8 parts of polyoxyethylene lauryl ether, 6 parts of sodium fluorosilicate, 2 parts of coal gangue, carbon black 15 parts, 2 parts of trichlorofluoromethane, 4 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 6 parts of aluminum borate whiskers, 12 parts of hydrated silicic acid, 9 parts of sodium antimonate, 3 parts of diisopropylamine and tristearic acid 7 parts of glycerides.

[0020] A preparation method of a sealing strip for an automobile window, comprising the following steps:

[0021] 1) 22 parts of polyvinyl chloride, 40 parts of EPDM rubber, 6 parts of paraffin wax, 7 parts of polyacrylsiloxane, 12 parts of te...

Embodiment 2

[0028] A kind of sealing rubber strip of automobile window, is made of the following materials of proportioning by weight, comprises polyvinyl chloride 24 parts, EPDM rubber 42.5 parts, paraffin wax 8 parts, polypropylene adiene siloxane 9 parts, 13.5 parts of tert-butyl hydroquinone, 19 parts of diisobutyl phthalate, 11.5 parts of mercaptoester, 10 parts of polyoxyethylene lauryl ether, 9 parts of sodium fluorosilicate, 3 parts of coal gangue, carbon black 17.5 parts, 2.5 parts of trichlorofluoromethane, 6 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 8.5 parts of aluminum borate whiskers, 13 parts of hydrated silicic acid, 12 parts of sodium antimonate, 5.5 parts of diisopropylamine and tristearic acid 9 parts of glycerides.

[0029] A preparation method of a sealing strip for an automobile window, comprising the following steps:

[0030] 1) 24 parts of polyvinyl chloride, 42.5 parts of EPDM rubber, 8 parts of paraffin wax, 9 parts of polypropylene adiene sil...

Embodiment 3

[0037] A kind of sealing rubber strip of automobile window, is made of the following materials of proportioning by weight, comprises polyvinyl chloride 26 parts, EPDM rubber 45 parts, paraffin wax 10 parts, polypropylene adiene siloxane 11 parts, 15 parts of tert-butyl hydroquinone, 20 parts of diisobutyl phthalate, 14 parts of mercapto ester, 12 parts of polyoxyethylene lauryl ether, 12 parts of sodium fluorosilicate, 4 parts of coal gangue, carbon black 20 parts, 3 parts of trichlorofluoromethane, 8 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 11 parts of aluminum borate whiskers, 14 parts of hydrated silicic acid, 15 parts of sodium antimonate, 8 parts of diisopropylamine and tristearic acid 11 parts of glycerides.

[0038] A preparation method of a sealing strip for an automobile window, comprising the following steps:

[0039] 1) 26 parts of polyvinyl chloride, 45 parts of EPDM rubber, 10 parts of paraffin wax, 11 parts of polypropylene adiene siloxane, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com