Preparation method of diisobutyl phthalate

A technology of diisobutyl phthalate and isobutanol, which is applied in the field of preparation of diisobutyl phthalate, can solve the problems of harmful crops, unfavorable crop growth, unsuitable and other problems, and achieves no by-products, good The effect of industrial application value and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

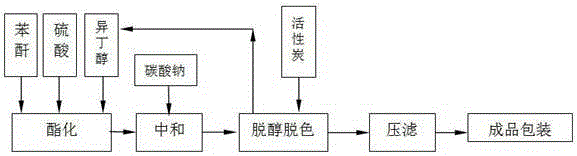

[0028] Example: such as figure 1 Shown, the preparation method of this diisobutyl phthalate comprises the following steps:

[0029] (1) Preliminary preparation: Weigh the raw materials in proportion, and test the reaction equipment; the raw materials are composed of the following ingredients in parts by weight: 6000KG of phthalic anhydride, 6000KG of isobutanol and 30KG of sulfuric acid;

[0030] (2) Esterification reaction: Put the weighed raw materials into the esterification kettle, and heat to 140°C for esterification reaction; after 2 hours of reaction, add 2500KG of isobutanol. When replenishing isobutanol, the temperature is controlled at 135°C. Alcohol supplementation time is 1h; esterification reaction time is 8h, after the reaction, take a sample to test the acidity value; after the esterification reaction, the acidity value is 0.3KOHmg / g up to the standard.

[0031] (3) Neutralization reaction: transport the material whose acid value reaches the standard after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com