A kind of high temperature and high pressure resistant electrolyte solution for sulfur lithium battery and preparation method thereof

An electrolyte and high-temperature-resistant technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as increased battery impedance, damage to battery performance, and accelerated thermal decomposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

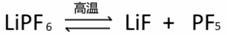

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a high-temperature and high-pressure-resistant electrolyte solution for lithium-sulfur batteries, comprising the following steps: placing lithium hexafluorophosphate in a vacuum drying oven, and drying at a temperature of 80°C for 5 hours; then, using gloves under the protection of an inert gas In the box, dissolve the dried lithium hexafluorophosphate in the propylene carbonate solvent, shake well, and let it stand for 10 hours to obtain the basic electrolyte; finally, in the glove box under the protection of inert gas, the o-(diethyl)aminoacid Oxysilane and bis(diethyl)aminoacyloxysilane mixed electrolyte additive and trimethyl phosphate flame retardant additive were added to the base electrolyte.

[0034] More specifically, the synthesis method of the electrolyte additive, the specific process is as follows: add the dehydrated ethylenediamine and isopropanol solvent into a dry reaction kettle, and add acyloxysilane under the protection of an ine...

Embodiment 2

[0036] A method for preparing a high-temperature and high-pressure-resistant electrolyte solution for lithium-sulfur batteries, comprising the following steps: placing lithium hexafluorophosphate in a vacuum drying oven, and drying at a temperature of 80°C for 5 hours; then, using gloves under the protection of an inert gas In the box, dissolve the dried lithium hexafluorophosphate in the propylene carbonate solvent, shake well, and let it stand for 10 hours to obtain the basic electrolyte; finally, in the glove box under the protection of inert gas, the o-(diethyl)aminoacid Oxysilane electrolyte additives and trimethyl phosphate flame retardant additives are added to the base electrolyte.

[0037] More specifically, the synthesis method of the electrolyte additive, the specific process is as follows: add the dehydrated ethylenediamine and isopropanol solvent into a dry reaction kettle, and add acyloxysilane under the protection of an inert gas. ℃, reacted for 8 hours, wherein, ...

Embodiment 3

[0039] A method for preparing a high-temperature and high-pressure-resistant electrolyte solution for lithium-sulfur batteries, comprising the following steps: placing lithium hexafluorophosphate in a vacuum drying oven, and drying at a temperature of 80°C for 5 hours; then, using gloves under the protection of an inert gas In the box, dissolve the dried lithium hexafluorophosphate in the propylene carbonate solvent, shake well, and let it stand for 10 hours to obtain the basic electrolyte; finally, in the glove box under the protection of inert gas, the o-(diethyl)aminoacid Oxysilane electrolyte additives and trimethyl phosphate flame retardant additives are added to the base electrolyte.

[0040] More specifically, the synthesis method of the electrolyte additive, the specific process is as follows: add the dehydrated ethylenediamine and isopropanol solvent into a dry reaction kettle, and add acyloxysilane under the protection of an inert gas. ℃, reacted for 8 hours, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com