A kind of flame retardant foaming agent and its preparation method and application

A technology of foaming agent and foam material, which is applied in the field of flame retardant foaming agent and its preparation, which can solve the problems of increased processing difficulty, high coating content, and destroyed cell structure, and achieves excellent flame retardant effect and excellent mechanical properties. Excellent, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

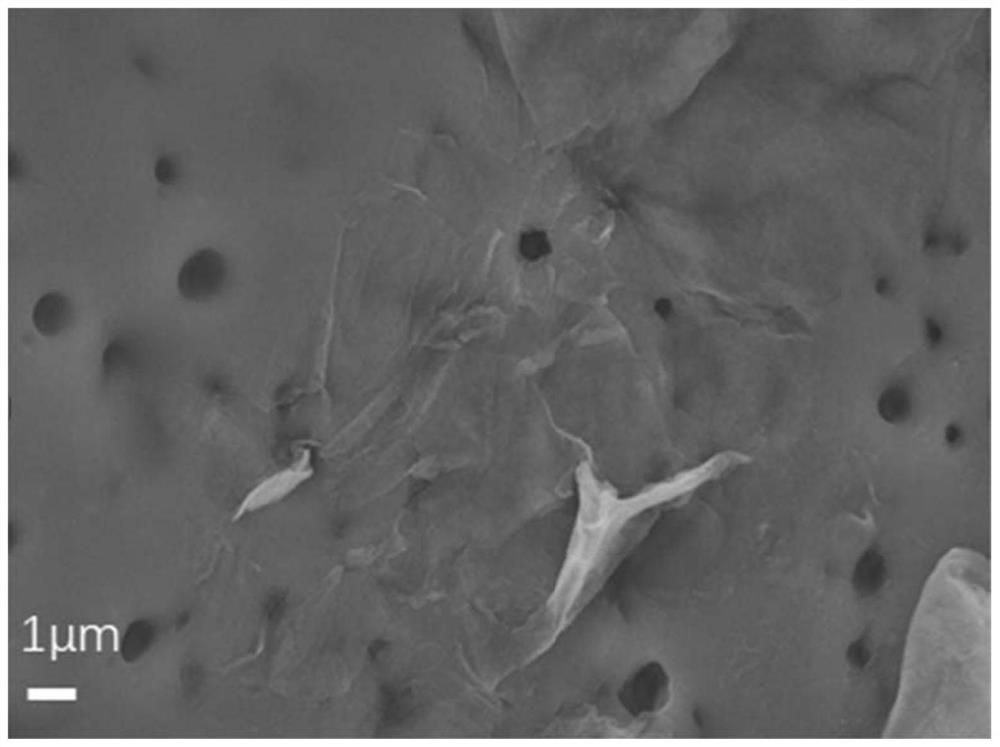

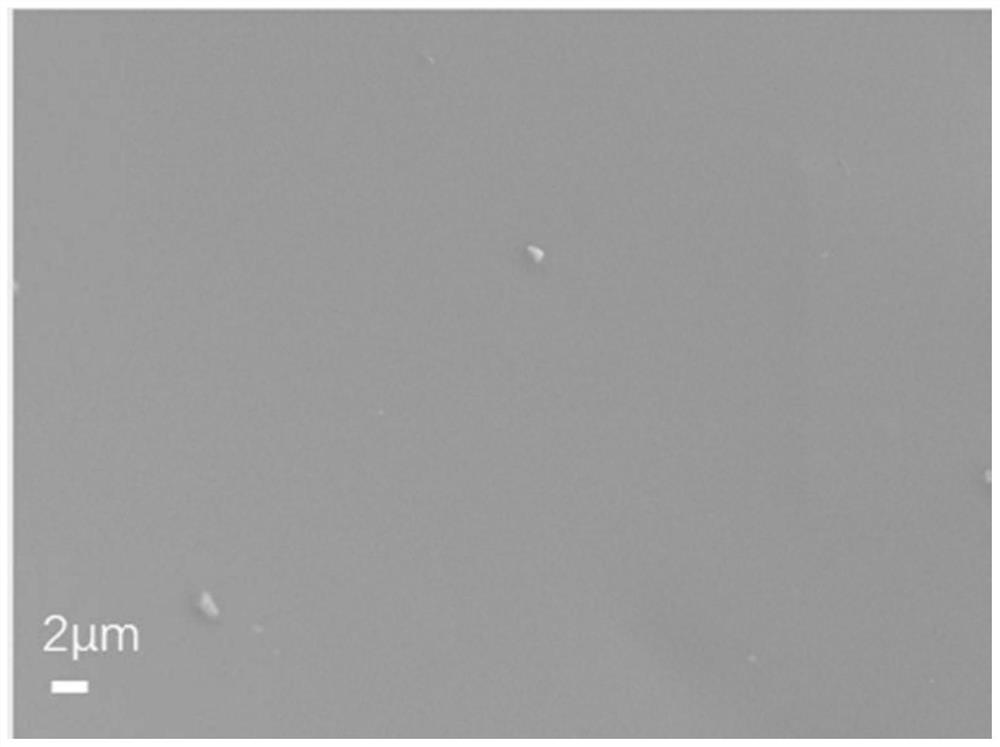

[0051] Take 0.2g of graphene oxide flakes with a diameter of 15μm and 20g of ethylene glycol, mix them evenly and place them at 100°C for 2 hours, then add 0.2g of trimethylsilanol and 20g of hydroxyl silica gel with a viscosity of 5000mPa·s, and stir them mechanically The foaming aid with flame retardant function can be prepared after mixing well and evenly.

[0052] Take 25g of hydrogen-containing silicone oil with a hydrogen content of 0.5% and a viscosity of 20mPa s, 55g of hydroxyl silica gel with a viscosity of 1 Pa s, 3.2g of a foaming aid and 0.01g of diallyl maleate, and stir them evenly to prepare A component; at the same time, take 40g of 1 Pa s hydroxy silica gel, 40g of vinyl silicone oil with a vinyl content of 0.3%, a viscosity of 1 Pa s and 0.4g of Castel platinum catalyst of 2000ppm, and mechanically mix them uniformly to prepare B component .

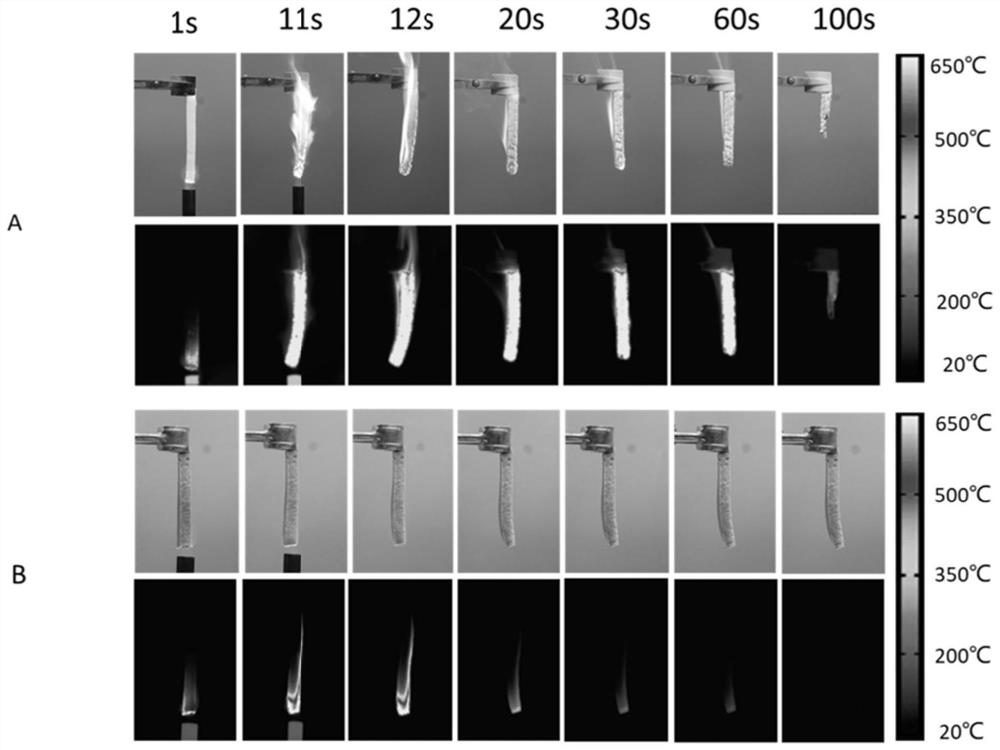

[0053] Take 20g of component A and 20g of component B respectively, mix well and evenly with mechanical stirring, p...

Embodiment 2

[0058] Take 0.15g of graphene nanobelts with a diameter of 20μm and 20g of neopentyl glycol, mix them evenly and place them at 100°C for 2 hours, then add 0.2g of L580 silicone surfactant and 20g of hydroxyl silica gel with a viscosity of 1Pa s , mechanically stirred and thoroughly mixed to obtain a foaming aid.

[0059] Take 30g of hydrogen-containing silicone oil with a hydrogen content of 0.5%, a viscosity of 50mPa·s, 50g of a hydroxyl silica gel with a viscosity of 2Pa·s, 4.5g of a foaming aid and 0.05g of 3-methyl-1-yn-3-ol, and mechanically Stir evenly to prepare component A; at the same time, take 40 g of 1 Pa s hydroxy silica gel, 40 g of vinyl silicone oil with a vinyl content of 0.3% and a viscosity of 1 Pa s, and 0.4 g of Castel platinum catalyst of 5000 ppm, and mechanically mix them uniformly to prepare B components.

[0060] Take 20g of component A and 20g of component B respectively, mix them well with mechanical stirring, place them in an oven at 80°C for 10 m...

Embodiment 3

[0062] Take 0.3g of lamellar nano-aluminum hydroxide with a diameter of 30 μm and 15g of diethylene glycol, mix them uniformly and place them at 100°C for 2 hours, then add 0.3g of Dow Corning 5562 alcohol ether silicone oil and 20g of them with a viscosity of 2Pa. s hydroxy silica gel, mechanically stirred and thoroughly mixed to obtain a foaming aid.

[0063] Take 30g of hydrogen-containing silicone oil with a hydrogen content of 0.5% and a viscosity of 200mPa·s, 50g of a hydroxyl silica gel with a viscosity of 2Pa·s, 3.0g of a foaming aid and 0.2g of ethynyl cyclohexanol, and mechanically stir to obtain component A Simultaneously, take 1Pa·s hydroxy silica gel 30g, vinyl content 0.4%, vinyl silicone oil 50g of viscosity 1Pa·s and 2000ppm Castel platinum catalyst 0.6g, mechanically mix to obtain B component.

[0064] Take 20g of component A and 20g of component B respectively, mix them well with mechanical stirring, place them in an oven at 80°C for 10 minutes to crosslink a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com