Energy-saving engineering machinery hydraulic oil with high viscosity index and ultralow temperature

A technology of construction machinery and viscosity index, applied in the field of hydraulic oil, can solve the problems of difficult to meet the hydraulic system, block the filter device, poor oxidation stability, etc., and achieve the effect of improving work efficiency, low temperature rise and easy start-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

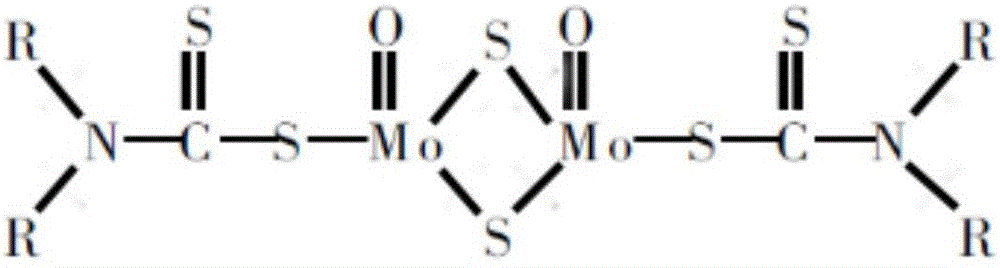

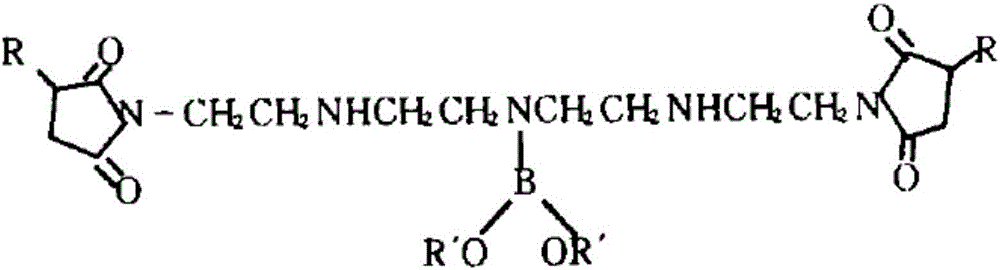

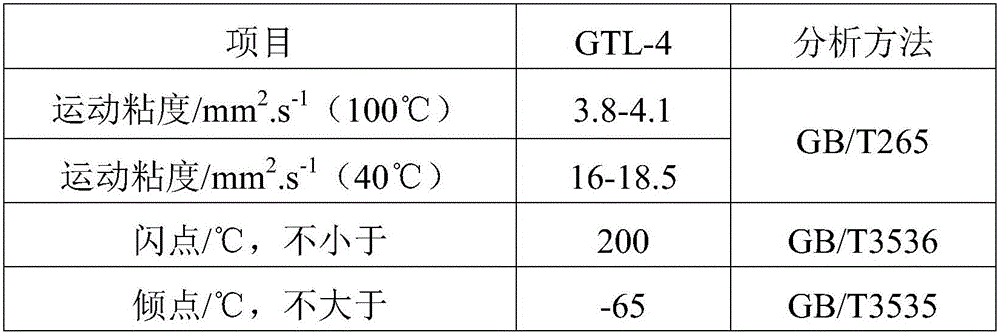

[0053] High viscosity index ultra-low temperature energy-saving engineering machinery hydraulic oil raw materials (parts by weight): 0.6 part of tricresyl phosphate, 1 part of molybdenum N,N-di(dodecyl)alkyl dithiocarbamate, 5 octadecylamine salt of benzotriazole 3 parts of ethylene glycol oleate, 80 parts of ethylene-propylene copolymer, 0.5 parts of borated polyisobutylene succinimide, 2.1 parts of antioxidant, 3.4 parts of 4,4'-dioctyl diphenylamine, poly 5 parts of methacrylate, 0.01 part of simethicone, 650 parts of GTL-4 base oil, and 150 parts of 500N base oil.

[0054] The antioxidant is obtained by uniformly stirring and mixing 2,6-di-tert-butylphenol, 3,5-di-tert-butylphenol and 2,4-di-tert-butylphenol in a mass ratio of 1:1:1.

[0055] Add GTL-4 base oil into the blending kettle, stir at 400 rpm and heat up to 75°C, add polymethacrylate into the blending kettle, stir at 400 rpm for 0.5h, add antioxidant, 4,4'- Dioctyldiphenylamine, borated polyisobutylene succinimi...

Embodiment 5

[0057] Prepare high-viscosity index ultra-low temperature energy-saving construction machinery hydraulic oil according to the method of Example 4, the difference is only: the antioxidant is composed of 3,5-di-tert-butylphenol, 2,4-di-tert-butylphenol in mass ratio For 1:1 stirring and mixing to obtain uniformity. The high-viscosity index ultra-low temperature energy-saving engineering machinery hydraulic oil of Example 5 was obtained.

Embodiment 6

[0059] Prepare high-viscosity index ultra-low temperature energy-saving engineering machinery hydraulic oil according to the method of Example 4, the difference is only: the antioxidant is composed of 2,6-di-tert-butylphenol, 2,4-di-tert-butylphenol in mass ratio For 1:1 stirring and mixing to obtain uniformity. The high-viscosity index ultra-low temperature energy-saving engineering machinery hydraulic oil of Example 6 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com